Custom solutions within production

Custom Solutions for a connected world

With increasing demand on approval and compliance, AFRY assists you in improving your manufacturing. We bring your ideas into production - software, electronics, sensors, and mechanics combined into next generation products.

At AFRY, we specialise in end-to-end embedded product development through customised solutions adapted to your needs. Our seasoned teams of engineers and designers collaborate closely with clients to transform innovative ideas into tangible, market-ready solutions. We support you in the whole process from idea to research, design, product development and production. Here’s how we can assist you:

- Conceptualisation and Ideation:

- Idea Refinement: We work closely with you to refine your product concept, ensuring it aligns with your business goals and user needs.

- Market Research: Our experts analyse market trends, competitor offerings, and user pain points to create a robust product vision.

- Technical Specifications and Planning:

- Detailed Requirements: We meticulously document technical specifications, covering both software and hardware aspects.

- Budget Estimation: Our team provides transparent cost estimates, considering features, complexity, and scalability.

- Prototyping and Design:

- Proof of Concept (PoC): We swiftly create PoCs to validate feasibility and identify potential challenges.

- Hardware and PCB Design: Our engineers design efficient PCB layouts, considering e.g. signal integrity and power management.

- Software Architecture: We architect reliable and optimized firmware, drivers, and middleware.

- Software Development:

- Embedded Firmware: Our skilled developers write efficient, bug-free firmware tailored to your product’s requirements.

- RTOS Integration: For real-time responsiveness, we integrate robust real-time operating systems.

- Connectivity Solutions: We implement seamless communication protocols (Bluetooth, Wi-Fi, etc.).

- Hardware Implementation:

- Component Selection: We carefully choose components for reliability, performance, and cost-effectiveness.

- Prototyping and Testing: Our team builds physical prototypes for rigorous testing and validation.

- Testing and Quality Assurance:

- Unit and Integration Testing: We ensure each module functions flawlessly.

- Field Testing: Real-world testing validates performance, stability, and user experience.

- Production and Deployment:

- Manufacturing Setup: We establish production services, including AFRY inhouse production, ensuring consistent quality.

- Deployment Strategy: Whether B2B or B2C, we guide you through successful product deployment.

We meet the market’s increasing demand for managed outsourced assignments

Whether you need a single consultant with a certain competence, a product development team, or your entire project to be scoped and executed, AFRY has the experience, processes and know-how to deliver with excellence. At AFRY, we have over 10 years of experience in delivering solutions through a highly efficient methodology that can be adapted to any client.

One of the keys to success is careful management and continuous improvement of our intellectual and structural capital. Our established processes with integrated governance structures enable us to take on full responsibility for an entire project or product lifecycle while keeping the client continuously involved in the assignment’s execution.

To meet the varying needs of our clients, we offer three delivery models; Managed Agile Teams, Projects and Product Lifecycle Management.

The set-up will be designed and optimised for the specific assignment as well as the client’s desired level of involvement.

In addition, AFRY is an experienced partner when it comes to coaching our clients on how to introduce, maintain and reinforce agile WoW and Lean principles within their organisations.

Our Delivery Models

- Managed Agile Teams

- Full Projects Delivery

- Product Lifecycle Management (PLM)

- Production incl. PoC & Prototyping

High performing agile teams with many years of experience

Being one of the pioneers in delivering Managed Agile Teams, AFRY has the processes, experience and know-how to build efficient teams, easily adapted to your organisation. We build highly competent and versatile teams and our client experience range from Telecom and Automotive to Medtech and IT.

In order to seize an upcoming business opportunity, client organisations often face situations where the number of products in parallel development is higher than their current capacity, or competence requirements of certain products outside of their employees’ competence set. AFRY Managed Agile Teams is an extended muscle to that client organisation with the benefits of:

- Fast ramp-up & ramp-down

- No need for time consuming & expensive recruitment process

- Access to AFRY’s competence network of 17 000 employees and 35 000 partners

- No client need for management, team coaching/follow-up

- Access to AFRY’s vast experience in Agile methodologies and ways of working

The client’s agile organisation is responsible for defining the competence & capacity needed and appoint a Product Owner steering the teams’ work through a prioritised backlog. Based on this information, the AFRY Team Manger uses well established processes and methods in order to form a high performing team ready to reinforce the client organisation bridging their current gap in competence or capacity.

Key offerings

- High performing teams

- Cross-functional teams

- Off-site teams

- Fast ramp-up

- Knowledge injection to client organisation

We take on your product development projects from start to finish

We deliver managed product development projects where we take on full responsibility throughout the entire project lifecycle, from definition of requirements to final delivery.

We design, set-up and optimise your product development project for your particular needs. A project delivery from AFRY gives you many benefits:

- It enables you to deliver technology outside your core business.

- It gives you the possibility to utilise specialist competence that does not exist within your own organisation.

- Facilitates budgeting since a forecast of the total project cost is part of the delivery.

- Eliminates the need to provide resource management since we take full responsibility for recruitment and staffing according to the project’s needs.

- Eliminates the need to provide project management since we assign a project manager who will be responsible for operative management and leadership throughout the project’s execution.

- Eliminates the need to provide office space since the project team will work from AFRY premises.

- Provides an established governance structure that ensures you the desired level of involvement and control throughout the project execution.

- Allows the possibility to agree on the delivery of pre-defined objectives and goals for each project phase.

Our projects include development of products containing embedded systems and mechanics. Examples of delivered products are control units, monitoring systems and control panels for various applications in various sectors.

We deliver:

- Pre-Studies

- Requirements Analysis

- Product Development Projects

- Functional Safety Expertise

Life Cycle Management (LCM) involves overseeing the entire lifespan of a product or service, from conception to end-of-life. It encompasses concept, design, development, production, maintenance, support, and eventually, the end of its lifecycle. We provide two main delivery models:

- Fully outsourced LCM: Assuming responsibility for all product generations, past, present, and future.

- Maintenance and Support: End-stage maintenance and support.

Our aim is to relieve clients of product-related tasks, enabling you to focus on strategic activities. Outsourcing such responsibilities is common for non-core products, allowing internal resources to concentrate on high-value tasks.

Benefits:

- Reduced product management burden

- Enhanced focus on strategic tasks

- Leveraging external expertise for non-core products

- Cost savings, improved product quality, and shorter time-to-market durations

- Efficient resource allocation

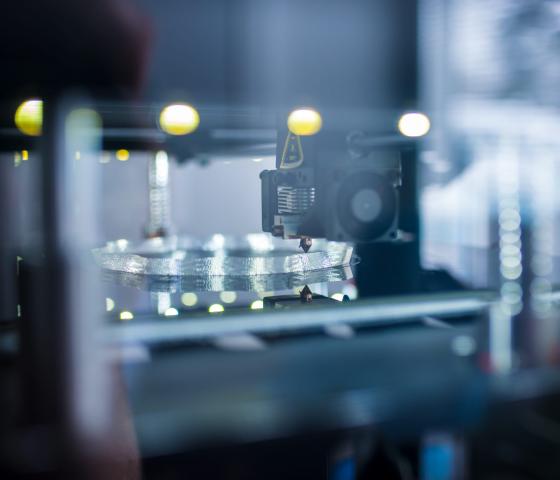

Product development with small volume production capability

AFRY Production Center has specialist expertise in high quality production for smaller series of electronics units. AFRY Production Center has established products in the market and established platforms and customers.

We conduct design, development and small-scale high-quality production. Today, a number of projects and serial deliveries are underway for customers in the industry, aeronautics, marine and defense industries. The products include sound systems, support systems, pilot microphones, moisture control systems and the production of electronics units for underwater systems.

Established routines and processes to handle quality level set by the authorities and by the customers. The processes include vendor management and evaluation, continuous improvement, review, export control regulations, internal and external audits, resource management, sales and marketing, R&D, testing tools and calibration.

Key offerings

- High quality small-scale production and R&D including all parts in product development

- Complete box build with PCB coating and casting

- Wiring and contracting and harnessing, design and manufacturing

- Mechanical machining and assembly

- Production test, functional test, FAI Packaging, delivery and control.

- Maintenance & Support

Proof of Concept & Prototyping

Demonstrate product feasibility by prototyping functional samples

Our experience in a wide range of industries will help you identify technologies that are available to solve problems in your design. This process typically begins with research and ends with proof-of-concept prototyping to prove out the solutions.

With the concepts approved, our mechanical, electrical and software engineers work in parallel to dig into the details and set out to prove the efficacy of the approach. We start building quickly and even crudely in order to first solve fundamental issues. We progressively mature the ideas through successive builds.

A Proof of Concept (POC) is a small exercise to test the design idea or assumption. The main purpose of developing a POC is to demonstrate the functionality and to verify a certain concept or theory that can be achieved in development.

Prototyping is a quick and effective way of bringing a client’s ideas to life and serves a sample for the potential users to evaluate, test and share their feedback to make improvements. This technique also helps in documentation and provides the team with a more accurate estimation how long it will take to complete.

We will assist you in both stages of development and assure your product will fulfil your requirements.

Key offerings

- Mechanical mechanisms

- Electronical hardware and software verification

- Additive Manufacturing methods and production

- Value increasing results

- Test rigs for e.g. endurance and cycling

- Verification of subsystems and/or complete systems

- Geometric assurance

Interested in our offering? Contact us!