Green Steel

Decarbonising the steel industry with new fossil-free production methods

At AFRY we are decarbonising the steel industry, and we are turning it fossil-free. Fossil reductants can be removed from steel production by adopting new processes, reducing CO2 emissions significantly.

The Green steel manufacturing process focuses on using electricity and non-fossil fuels, consequently reducing greenhouse gas emissions compared to conventional steel production.

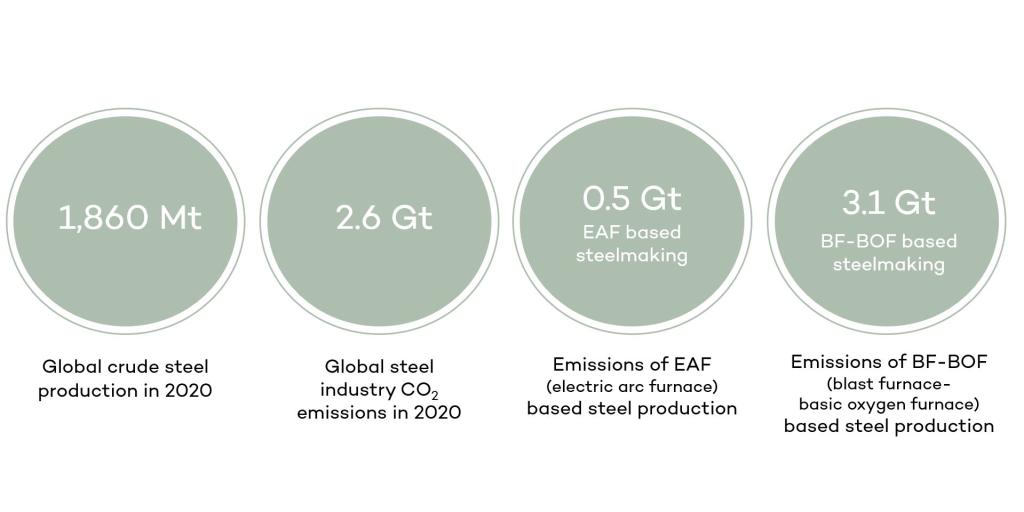

The Green steel process creates near zero CO2 emissions, while steelmaking currently contributes more than 7% of global carbon dioxide emissions. This makes decarbonisation a global priority in the steel industry.

A significant proportion of global steel production is currently based on the conventional blast furnace-basic oxygen furnace (BF-BOF) which contributed 3 Gt of CO2 emissions in 2019. Since fossil fuels, mainly in form of coal and coke, are used in conventional steelmaking in considerable quantities, shifting to non-fossil fuels is an important step for decarbonisation.

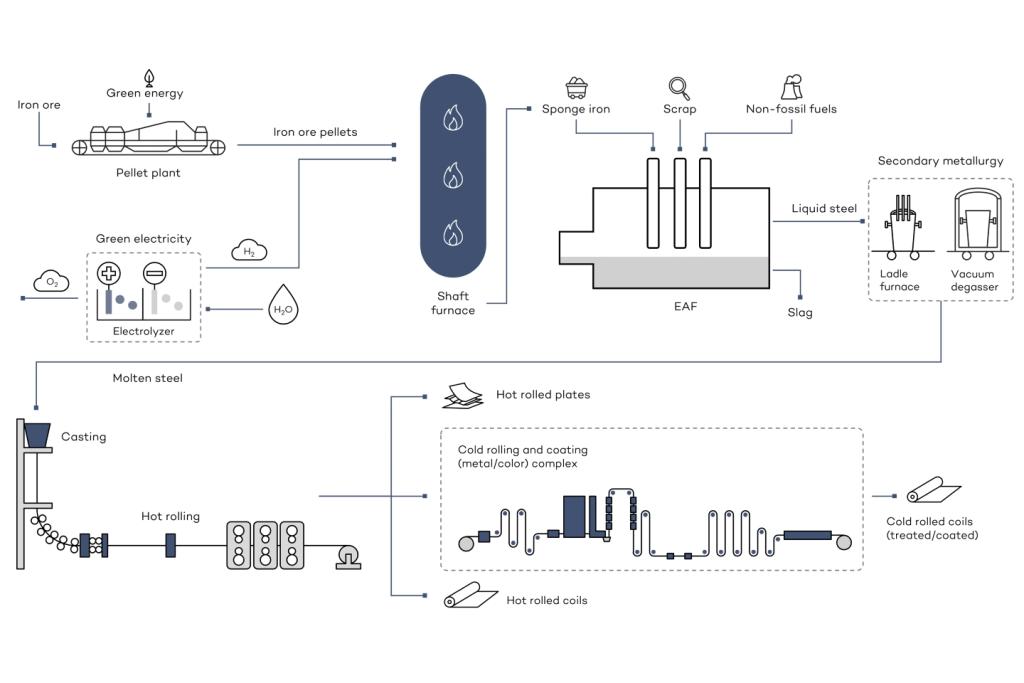

Hydrogen is one way for the steel industry to decarbonise. In this process, fossil fuels, such as coal, are replaced with green hydrogen that is produced from renewable energy and water. This way, CO2 emissions can be significantly reduced from the process. In addition to hydrogen, another way to decarbonise the process is by using fossil-free electricity. Depending on the availability of hydrogen and fossil-free electricity the reduction process can be also tailor-made to utilise a mix of hydrogen and natural gas with scalable mixing ratios. With the H2/NG mix significant CO2 reductions can be achieved compared to the traditional steel-making route.

At AFRY we help clients in shaping and developing their ideas into technically, environmentally, and financially viable solutions and offer services and support through the investment lifecycle. We are active in fossil-free Green Steel projects that are constantly developing new technologies to reduce CO2 emissions by more than 90%.

Green steel refers to steel produced using environmentally friendly and sustainable methods. This usually involves using renewable energy sources, reducing carbon dioxide emissions, and minimising and recycling waste during the production process.

The goal of green steel is to make the production of steel more environmentally friendly and reduce its impact on the climate. This can be achieved through various means, such as reducing the use of carbon-based reducing agents and fuels in pelletising, moving from blast furnace process route to electric arc furnaces fed with steel scrap and direct reduced iron and powered by renewable energy, converting from fossil-based fuels to hydrogen or electricity in downstream processing.

The concept of green steel is part of a larger movement towards a more sustainable and eco-friendly industrial production process.

Green steel is made with a combination of various methods and technologies that aim to reduce the environmental impact of steel production. Here are some of the key steps in the production of green steel:

- Use of renewable energy: Green steel production relies on using renewable energy sources, such as wind, solar, and hydropower, to power the furnaces and other production equipment.

- Use of green hydrogen-based direct reduced iron: Replacing natural gas in direct reduced iron process reduces carbon emissions.

- Scrap steel recycling: Green steel production utilises scrap steel as a raw material, which reduces the need for primary resources and reduces the environmental impact of steel production.

- Carbon capture and storage: Remaining carbon dioxide emissions can be captured and stored rather than released into the atmosphere.

- Use of clean technologies: Green steel production uses technologies that are cleaner and more efficient, such as electric furnaces for melting, and downstream treatment of the steel.

- Minimisation of waste: Green steel production aims to minimise waste through practices such as recycling by-products, and utilising efficient production methods.

These steps help to minimise the environmental impact of steel production and make it more sustainable. However, it's important to note that green steel production is still in its early stages as steel companies, both old and new, are aiming to have their first plants up and running by mid to late 2020s.

Green steel is important for several reasons, including:

- Sustainability: Green steel production reduces the environmental impact of steel production and helps to make it more sustainable. This includes reducing carbon emissions, reducing the use of non-renewable energy sources, and minimising waste.

- Climate change mitigation: Steel production is a major contributor to greenhouse gas emissions, and green steel production helps to mitigate the effects of climate change by reducing emissions and increasing energy efficiency.

- Economic benefits: Green steel production can create new jobs and stimulate economic growth, as well as improve the competitiveness of the steel industry.

- Consumer demand: There is growing demand from consumers for environmentally friendly products, and green steel production helps to meet this demand.

- Legal requirements: Many countries have set targets and standards for reducing greenhouse gas emissions, and green steel production helps to meet these requirements.

Overall, green steel represents an important step towards a more sustainable future and a cleaner environment. By reducing the environmental impact of steel production, green steel can help to conserve resources, mitigate climate change, and promote economic growth.

Green steel can be used for a wide range of applications in similar way as conventional steel including:

- Construction: Steel is a commonly used material in construction, and green steel can be used for various applications such as building structures, bridges, high-rise buildings and construction equipment.

- Transportation: Green steel can be used in the production of vehicles, ships, and trains, helping to reduce the environmental impact of transportation.

- Energy: Green steel can be used in the production of wind turbines, solar panels, electrical equipment and other renewable energy technologies.

- Packaging: Steel is a commonly used material in packaging, and green steel can be used to produce environmentally friendly packaging solutions.

- Consumer goods: Green steel can be used in the production of a wide range of consumer goods, such as appliances, furniture, and electronics.

- Infrastructure: Green steel can be used in the construction of infrastructure, such as roads, pipelines, and water systems.

In general, green steel can be used in any application where conventional steel is used, with the added benefits of being environmentally friendly and sustainable. Use of green steel helps to reduce the environmental impact of these products and promote a more sustainable future.

Decarbonising steel requires new production methods

Fossil fuels can be removed from steel production by adopting new processes, reducing CO2 emissions significantly. Replacing fossil fuels with non-fossil fuels in the process is one way to decarbonise the steel industry.

AFRY's capabilities cover the whole project lifecycle

If you are looking for a partner to help you achieve your green steel goals, our engineering team is here to assist. Our team of experts is dedicated to providing innovative and sustainable solutions for the production of green steel. From the initial feasibility study to the development and implementation of your project, we provide a comprehensive range of engineering services to help you achieve your objectives. We are technology independent and we offer our own solutions every step of the way.

Our competencies:

- Feasibility studies with various CAPEX and OPEX accuracies

- Health, safety and environmental studies, permitting and EIA support

- Multi-disciplinary engineering services

- EPCM (engineering, procurement, project and construction management) services

- Technical consulting, Management consulting services, including technical due diligence studies and process optimisations

- Sustainability services

- Digitalisation services

- Metallurgical support

The industry needs extensive production of green hydrogen

In order to achieve a carbon-free transition to green steel, the industry must focus on extensive production of green hydrogen using electrolysis. Low carbon and renewable hydrogen offer a viable route to decarbonise the iron and steel sector. Our expertise spans the hydrogen value chain, from thought leadership and business concept design to feasibility studies and project implementation.

Sustainable mining and metals are critical to the transition to a low-carbon future

Minerals and metals are essential building blocks in a wide variety of clean energy technologies. AFRY is committed to following sustainable mining and metals industry principles targeting to minimise negative environmental, social, and economic impacts associated with mining and minerals processing activities. Sustainable mining promotes resource efficiency, minimising waste, and embracing recycling and circular solutions.

Hydrogen is the core of Power-To-X

At AFRY, we believe that leveraging Power-to-X technology to produce hydrogen and synthetic fuels from renewable energy will be essential in meeting climate targets and a way to decarbonise the industrial, transportation, heat, and power sectors. Hydrogen can replace fossil fuels and fossil energy sources in a range of applications and be used in a variety of ways as a raw material, fuel, or energy storage medium.

Did you know?

Contact us

Our goal is to help you achieve your sustainability targets while maximising efficiency and profitability. Our team of experts has a proven track record of delivering successful green steel projects, and we are committed to helping you create a more sustainable future. Contact us today to learn more about how we can support your green steel project.