Bio-Based Textile fibres

Man-made bio-based cellulosic fibres pave the way for improved sustainability in the textile industry

We at AFRY support our clients in identifying and implementing business opportunities across the textile value chain. We work closely with our clients and assist them throughout the whole process, from evaluating project feasibility to design and project implementation.

Our society is shifting toward sustainability by knowing more about the impact of its past actions on the planet, so does the fashion industry. It undergoes the same transition following the sustainability trend. Rising consumer awareness has put pressure on fashion companies to reduce their social and environmental impact through new technologies and innovations for the circular economy. The novel bio-based textile fiber industry will play a key role in reducing the environmental footprint of the textile industry. Although the majority of novel textile fibres are still in relatively early stages of development, commercialisation is accelerated by partnerships in the value chain.

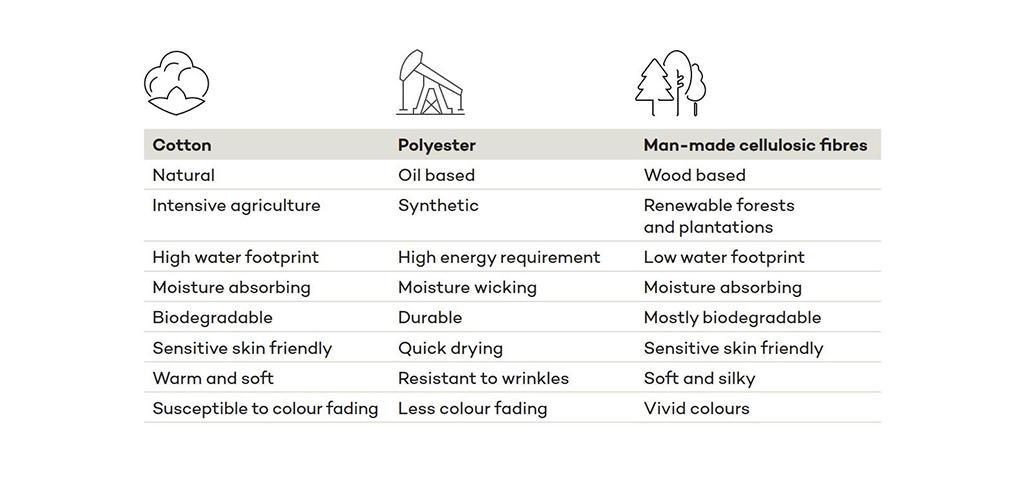

Historically, natural fibres such as cotton were the dominant type of fibre used for textiles. But cotton requires arable land which could otherwise be used for food production. In addition, cotton is also a water-intensive crop sensitive to its environment. With that in mind, it is unsurprising that the production of cotton has not increased much since the late 1980s. Today, the most common type of fibres used in textiles are synthetic fibres, in particular polyester. Although polyester is comparatively inexpensive and durable, its major drawback is that it is oil-based and is adding to the microplastics pollution problem in our oceans.

We are innovating the textile industry

We serve clients in assessing the maturity of bio-based textile fibre technologies, in modelling the competitiveness of man-made cellulosic fibres in relation to other fibres, and in discussing renewable textile fibre needs with brand owners. Our pre-investment study services provide an independent base for investment decisions combining all essential elements of an industrial project – technical, economic, commercial and environmental matters topped up with risk analysis.

Our deep understanding and competence in cellulosic fibres, our track record of long-standing cooperation with the world's largest pulp producers, combined with the extensive process industry and project execution experience, makes us a unique partner for textile clients in accelerating their novel fibers to scalable commercial production.

Interested in our offering? Contact us!