Assessing industrial production of different prehydrolysis kraft dissolving pulp grades

Selection of the mill concept has to be carefully evaluated from technical, economical and environmental points of view.

Written by Emma Kärkkäinen and Jarno Peltonen

The demand of dissolving pulp demand is expected to grow due to associated environmental benefits (e.g. substitution of highly water-intensive cotton products). Pulp technology is in the core of wood-based textile fibers production, since they are mainly produced from dissolving pulp.

Dissolving pulp can be manufactured from a variety of lignocellulosic materials, including both hardwood and softwood. Eucalyptus was selected as the raw material for the Case calculations of the thesis, due to its global availability and suitability for the prehydrolysis kraft (PHK) process.

Four dissolving pulp mill concepts were compared

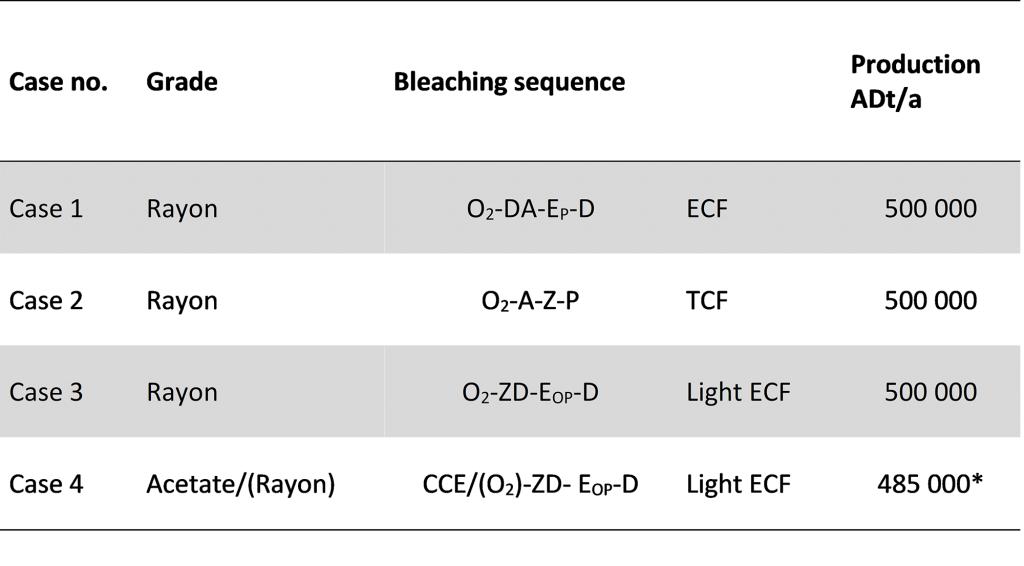

Four bleaching sequences with otherwise similar starting values were compared to demonstrate differences in mill-scale production through balance and investment cost calculations. Mills in Cases 1-3 produce rayon-grade dissolving pulp, whereas the mill in Case 4 alternates between rayon- and acetate-grade pulps.

Table 1. Product grades, bleaching sequences and annual production capacities in Cases 1-4.

While the department capacities for Cases 1-3 were mostly similar, the CCE (Cold Caustic Extraction) step in Case 4 required additional capacity in evaporation, recausticizing and lime reburning. As the recovery boiler size was kept constant in all the cases, the pulp production capacity was scaled down in CCE production, resulting in a decrease in annual dissolving pulp output.

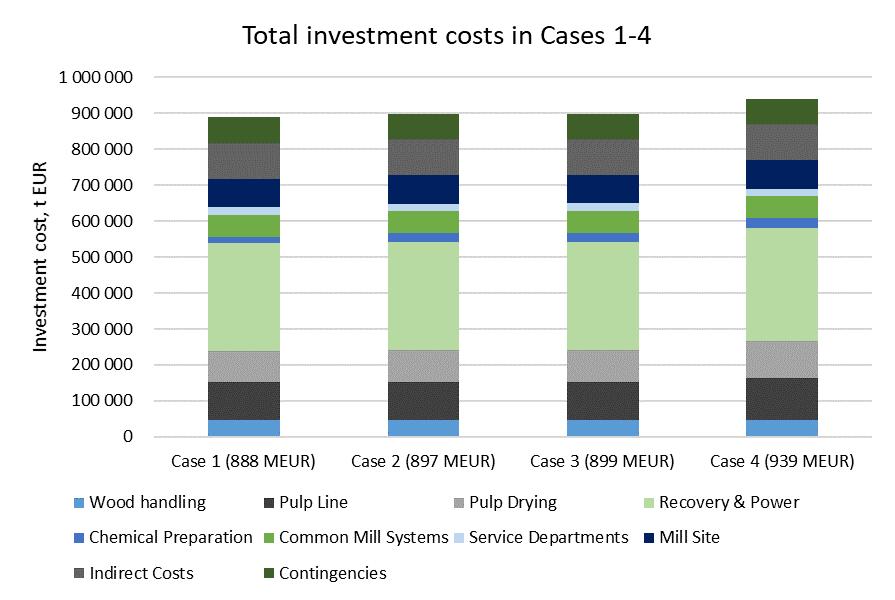

Investment costs were compared

The investment cost estimates (excluding certain mill specific costs) were very similar in Cases 2 & 3, whereas Case 1 featured the lowest investment costs. As the addition of a CCE step requires additional equipment and capacity, the CAPEX was highest in Case 4.

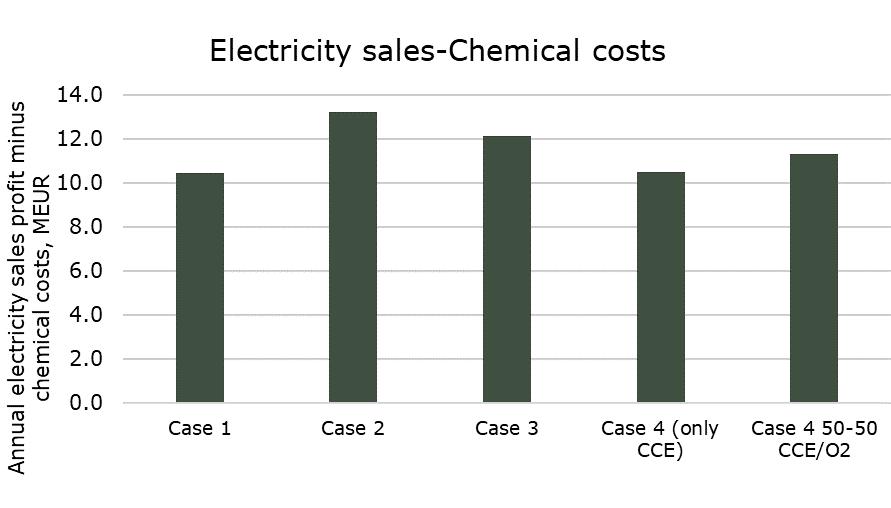

OPEX demonstrated differences between concepts

In a limited OPEX review, the profits from annual electricity sales were subtracted by direct chemical costs to demonstrate the effect of both on-site chemical production as well as the cost of purchased chemicals (Figure 2). The TCF bleaching in Case 2 resulted in the most profit, whereas the lowest profit from electricity sales was associated with Case 1 (and Case 4 in CCE production).

Conclusions

The comparison of Cases demonstrated that different dissolving pulp grades set different requirements for the pulp mill. Additionally, other factors have to be taken into account, like pulp bleaching (ECF or TCF), which directly affect bleaching chemical plant of the mill. Mill energy concept and local environmental requirements also affect the process design. The concept selection also has an effect on the profitability of the mill. Therefore, the interrelated technical and OPEX aspects have to be evaluated carefully. It was clearly demonstrated that process design decisions can amount to significant differences (e.g. chemical costs). Therefore, mill design should always be performed independently on a case-by-case basis.

AFRY has very strong global expertise in pulp technology and management consulting with dozens of dissolving pulp mill project references. We can independently evaluate different mill concepts from the required perspectives and help our clients to develop, implement and operate sustainable, efficient and economically feasible dissolving pulp mills. AFRY can be your partner in assessing the processes and their impacts, since a more sustainable future is in the focus of all stakeholders in the forest industry.