Business Continuity through Supply Chain Risk Management

SCRM contribute to a successful business with minimized risk exposure

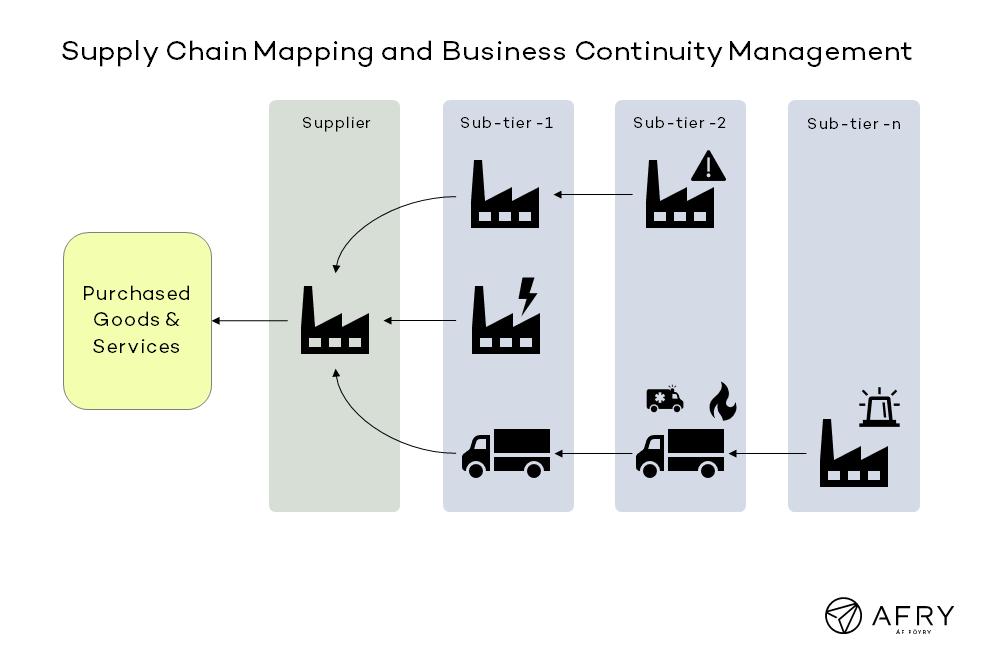

The Supply Chain of today is more complex than ever, highly dependent of inbound and outbound deliveries to a global market. Failure to consider the risks in the supply chain could generate devastating results and consequences. The survival of a company could be endangered when risks become reality.

What is SCRM?

Supply Chain Risk Management (SCRM) is the implementation of activities to manage both common and extraordinary risks end to end throughout the supply chain. The method origins from continuous risk assessment with the objective of reducing vulnerability and ensuring continuity. Basically, it’s a method to secure that the business is running properly.

The Supply Chain of today is more complex than ever, highly dependent of inbound and outbound deliveries to a global market. This is a great development where we can source and sell globally compared to a locally limited supply chain.

However, with great complexity the risks are increased. Failure to consider the risks in the supply chain could generate devastating results and consequences. The survival of a company could be endangered when risks become reality.

The SCRM approach follows the steps identification – assessment – controlling – monitoring and can be applied on different areas, such as procurement, logistics or sales. The focused actions might also differ, depending on the area in question. For example, the procurement area will focus on category plans and flows from different upstream tiers, the logistics will go for visibility and responsiveness in the supply plan, and the sales area will be interested in customer experience and behavior.

Properly done, the SCRM method will contribute to a successful business with minimized risk exposure.

Case Study: “Digitalisation of Supply Chain Risk Management”

An AFRY customer from the MedTech industry was looking for help to identify and quantify risks in its upstream supply chain. The requirement was to understand where Business Continuity is threatened by unawareness of critical sourcing routines.

The organization wanted to understand if their supplier base is aware of possible supply interruptions, and if mitigation policies are in place. Such precautions can be safety stocks, redundancy and relocation possibilities of manufacturing equipment, or multiple sub suppliers for critical raw material. Some companies have such mitigation scenarios summarized in a well-reviewed Business Continuity Plan. To increase robustness of the risk identification, sub-tier suppliers should be included in the evaluation, as well as producers of critical raw materials, which are difficult to procure, or difficult to requalify a new source for.

In order to gain this required Business Insight, the transparency on the Supply Chain had to be increased with a structured approach and proven IT tools, such as AFRY Portal & Repository Solutions (AFRY PRS).

AFRY supported with the creation and implementation of a Supplier Survey Tool for Business Continuity Management. A digital process was created to collect information throughout the supply chain on article level, to ensure continuity between the product portfolio and the purchased goods. The resulting application integrates into the existing IT landscape through standardized import / export functionality.

As a result, the new process and tool allow to acquire and collect data in a systematic way and transform it into business insight. This insight can be used for predictive measures to improve supply chain robustness.

To reach adaptability this insight can feed into Supplier Quality Assurance activities or future procurement decisions. Here Digitalization creates central insight hubs for collaboration, which aid business execution by connecting stakeholders and providing a valuable, aggregated source of truth.

Combined Capabilities

AFRY’s combined capabilities

With domain expertise from the Supply Chain Management, Risk Management and Digitalization AFRY can offer services and tools to increase transparency and awareness of risks within the supply chain. Structured methods and support systems can frontload evaluation and mitigation of threats before they lead to negative impacts on the operation.

Increasing complexity in today’s supply chains comes with increasing uncertainties for cross functional and cross company cooperation. The resource dimensioning in the supply chain is depending on trustworthy information regarding variations in lead times, order volumes, available capacity in the chain of resources.

Proactive screening for risks and aggregated up-to-date information that can be provided essential insights to prompt and well-structured exception handling. This is a strong enabler to minimize previously mentioned uncertainties and strongly improve the operational decisions in the planning process. Adaptive measure can be changed lot sizes, changed order sequence, or automated communication to other stake holders in the supply or demand chain.

This kind of information availability through integrated IT Solutions is the way to a highly responsive organization, with high delivery performance, higher stock turnover and less misunderstandings.

IT Solutions like AFRY Portal & Repository Solutions (AFRY PRS) - are packaged offerings to increase efficiency and transparency when sourcing and operating in a complex and global context. The AFRY PRS applications are web-based communication and information platforms designed for traceable, customised and transparent data management both between internal stakeholders and suppliers.

With AFRY and the PRS systems, all relevant data will be efficiently collected with a high collection rate and expected benefits such as time, cost and risk reduction due to improved operational efficiency, communication and cross-functional collaboration.