Change in the carton

When it comes to adapting to inevitable change, Michael Doss is certainly the man to talk to. The President and CEO of the Fortune 500 corporation Graphic Packaging has been with the company for over 30 years. Old-fashioned? Why it is not and how Mike's shaping the challenges posed by a pandemic, digitalisation and the circular economy.

Mike, you have worked at Graphic Packaging for over 30 years, having been President and CEO since 2016. Yet, we learned that you have the feeling of having worked for different companies in that time due to the changes at Graphic Packaging, especially due to M&As. What role does change in the business play for you personally?

My career started almost 32 years ago at a company called James River Corporation, and it was a very different industry at that time. I remember walking into our carton plant in Kalamazoo, Michigan. In those days, there were nine printing presses running Kellogg’s on a number of the presses, including Corn Flakes and Rice Krispies and other brands that I had grown up with.

I was halfway through my MBA and I only wanted some practice interviewing, but I remember just being so taken aback by what they were doing there in this factory that I said to myself, you'd better get your act together here. This is a real company. You may want to work here and get your head in the game. And so the rest is history. They made me an offer, and I started in the sales and marketing training programme. From there, I progressed into operations management, general management, then senior management and finally, the role that I am in today.

Along that journey, we went through four major evolutions in terms of acquisitions and different companies that I felt that I had been working for. Every one of those phases was different from a cultural standpoint and the needs of the business, the people and the customers were different. During such processes, I think that it is important to take the opportunity to figure out what is really core, what you are really good at as a company and what you can change. When I say change, I mean that the company you are merging with or acquiring is probably doing something better than you, which is why you are interested in buying them. If you can identify what that is, it is about working to scale that across the whole corporation. I grew tremendously as a manager in that environment.

How do you inspire new talent and give them that WOW feeling that you show for your work and the industry?

It's important to get our message out as an industry. We have such a good story to tell about opportunities for the bio-based economy, forest products and pulp and paper. One of the things I really want to do is work hard to attract younger people who are contemplating a career in our industry.

The best way to do so is by getting them excited about what we do. And I'll tell you something, our employees get excited. They go on vacation and see the products they make on the shelves. Or they go into a coffee shop and see Graphic Packaging on the top of the lid. And they'll shoot pictures of that on their phone and they'll send them to me. I could not be happier about that because that is really what you want, that ultimate pride in what we make and the role they play as essential workers. During the pandemic, it was very apparent that when you are 40% market share on folding carton in the US, it is important to do your job and get your products to the customers, or people will not eat. That helps our employees understand how important their jobs are and that they play a critical role in the supply chain here in the US, Europe and elsewhere around the world.

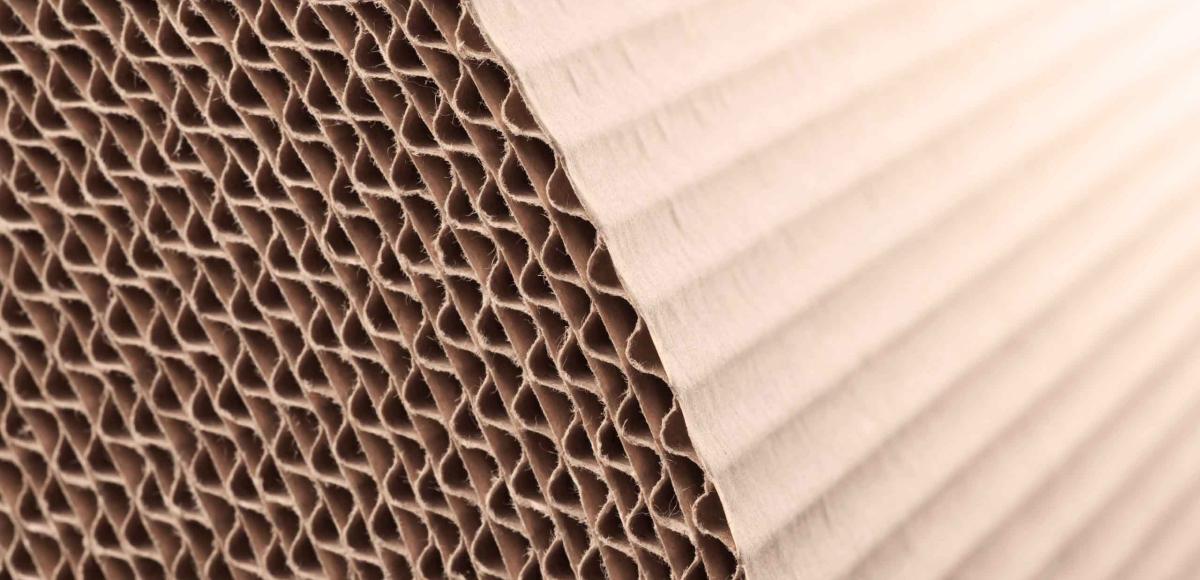

We produce fibre-based consumer packaging based on both virgin and recycled raw material. The raw material can be recycled up to 5 to 7 times to make primary packaging, not just recycled into other downstream uses. This is appreciated by our employees and customers alike.

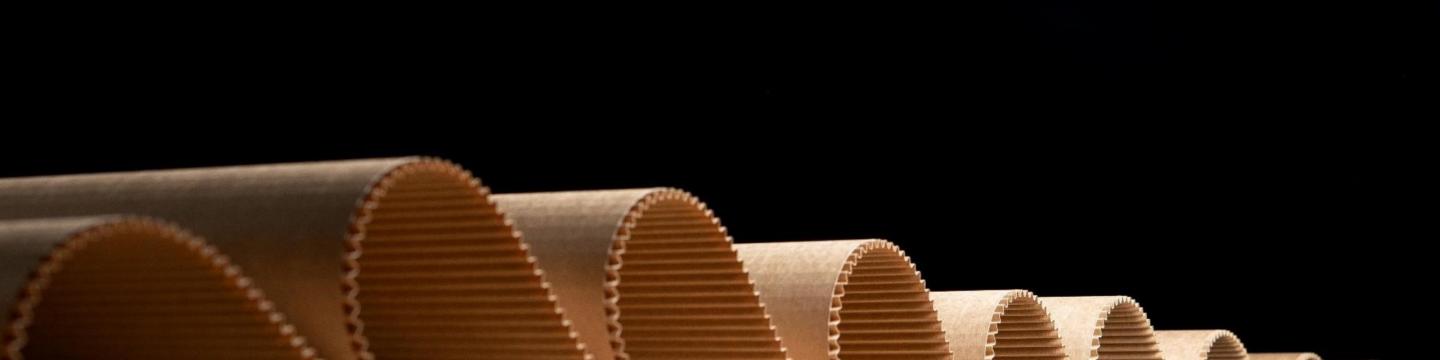

We can take the hydra pulper and skim off all the low-density PE on the surface and then take that fibre and reuse it again in a cereal box, which is just incredibly exciting. To me that is a kind of intersection to the circular economy.

When it comes to climate change and its impact on the industry, Graphic Packaging has a great sustainability story to tell. Do you see yourself as a pioneer on the road towards a circular economy?

I do not really know that we are pioneers because the technology has been out there for a while. We need the end-users, i.e., consumers, to really embrace it. I think we have done a good job in getting our message out in building our company to be able to really leverage circular economy from an operating standpoint.

Sourcing certified fibre from sustainably managed forests to go into our virgin mills is very important. We make sure that the logging is done correctly and that we are replanting at a rate that far exceeds what we're actually harvesting. We see this as a crop and a critical raw material for us. It is very important that we do that as an industry globally. And then, we turn the virgin material into something like a paper cup or a beer carrier.

We reclaim the used packaging through good curbside recycling and other collection systems and get it back to our mills. Today we collect over one million tonnes a year.

Then it goes back out in a primary package and we start the whole process over again. What we are doing on new product innovation and development is important, as are the big investments we are making to drive meaningful capability development.

Cost efficiency is another important factor, because we have to work the cost side of the equation for the customers, too. Particularly in a world where energy is going to be more expensive, we need to reduce water use, consume less electricity and improve fibre yields. The technologies are out there to enable us to do so.

Your strategy has been characterised by a strong focus on growth and sustainability. What is your vision for the future and how are you, as the leader, taking the company forward on its road?

This is the only job I have ever had, and it is the only job I ever want to have. Some people move from industry to industry, and that is fine for them. For me, this really is something I am passionate about. I really care about it.

One of my frustrations right now, which I am working with our end use customers to improve, is that recycling in the United States is still not where it needs to be. When you look at Europe, the curbside is so much more advanced and statutory in terms of how things are recovered. The waste streams are just a lot cleaner. There is more value in that. When I drive down the road here in Atlanta, I am constantly faced with how we recycle, which is largely by throwing everything in the trash. The single stream is better than nothing, yet it is not enough. We have made more progress with people really understanding that climate change is real. If we can use that as a backdrop to get better drive, even incremental changes, as things won't happen overnight, I am encouraged.

Another thing I am encouraged about is that the bio-based by-products from pulp production are becoming incredibly valuable. Corn cannot be used as a feedstock for many applications anymore because we need to make sure we feed people. In our industry, by managing the virgin mills efficiently, we create a lot of our own electricity by burning our black liquor. By-products such as tall oil and acidulated soap, turpentines and rosin that are used in various other industries are quite valuable to us. We spend a lot of time at Graphic Packaging considering value-adding uses for our by-products, which on the one hand, lowers our overall cost and, on the other, helps our communities. For example, 100% of the tree is used, including the bark that we are burning, instead of purchasing natural gas, which in turn reduces our use of fossil fuels and puts less pressure on natural gas prices. It is about becoming as efficient as possible, and that is why we are adding resources at Graphic Packaging to help us think differently. We are working with folks like yourselves to understand which projects will be most impactful in the long term.

What are the key lessons you have learnt from the progress made in product innovations, and how are you planning to take that to the next level as one of the key levers for growth?

I think the answer is twofold. Our end-use customers are facing a lot of challenges right now, such as inflation; there are troubles not just in packaging but also in food and transport logistics. This means that our customers need to raise prices, which opens a risk of losing elasticity on their brands and ultimately, consumers may be trading down or trading towards store brands.

But they need to do that to offset their inflation and keep their gross margins where they want them to be. At the same time, we support them in increasing visibility on the crowded shelves of grocery stores through our technologies that help advance the sustainability of packaging, as that is an increasingly important factor for the end customers.

Whether it is KeelClip or PaperSeal, or our fully enclosed cartons for beverages that are replacing shrink film in Europe, it is all-important because our customers have big goals to reach. By 2030 they want to cut down the amount of carbon they are generating by 40, 50, 60%. We can be part of that solution with the products that we are providing. One of the biggest lessons we have had to learn is to make sure we are focused on a few key platforms where we can really target our resources and make a difference. If you try to do everything that comes down the pike, the result will not be as good as if you kept focus. That is why we have put out 100-200 basis points of growth as part of our Vision 2025, and we have now outperformed that for three years in a row. We have been up 300 basis points, and the analysts ask, “Mike, shouldn't you reset the target?” I am like: No, we are outperforming right now. I think it is better to outperform than to put new targets out there and then not hit them. This keeps everybody focused on improving our products and allows our product development team to take what I call moon shots, working on farther-out technology that – if it hits – will really be game-changing for our customers.

What can other industries learn from the (fibre-based) packaging industry in harmonising climate friendliness and business success?

In the same way that there are opportunities within our by-products, almost every industry has got some things they can take advantage of. The question is how to find them, how to really create a sustainable business model that encapsulates that something that you do and that you can invest in – and to have the courage then to actually make those investments. In our case, I have to give our board a lot of credit for this because, in our industry, when you announce a new paper machine, no investor gets really excited. They worry that there is going to be too much capacity, exceed budget or it may not work. Those are fair concerns, given some of the notable failures that have happened. Yet, if we do not make investments, we will not have a competitive industry that is there to really take the opportunities that our customers need our help with. It has been eye-opening for me how many of our end-use customers have said they are glad we made an investment.

You invested over USD 600 million in a new papermill in Kalamazoo, Michigan. What has been the effect of this investment in terms of digitalisation and sustainable production for Graphic Packaging?

Right now, we at Graphic Packaging have what I call a hundred years of paper-making technology on display. We have our K3 machine in Kalamazoo, which is a cylinder machine. It is largely valves and controls and is hand driven by operators who are in their sixties. We have some in their seventies, they just love working there. Then we have our K1 machine that is 30 years old running at 2,000 feet per minute with a curtain coater on it producing high-quality products. We have to have a highly professional workforce that knows how to operate the machine with numerous unsupported nips at such a high speed. Should you break one of the webs, a whole paper machine is down. And then we have K2, which is the most modern machine in North America – I think maybe even in the world in terms of how we operate it. Particularly with natural gas prices now being where they are, I would imagine it is probably the lowest cash-cost CRB production line in the world.

We have operators that we hired with really no paper industry experience at all. They learned in the classroom, and now we have to train young people who are very savvy digitally. These are kids that grew up playing video games and are very comfortable with technology. Now they are in our control room, making paper, and we are spending a lot of time thinking about the digitalisation part of K2, or the gamification. I think it comes back to what we were talking about at the beginning, on how to create attractiveness in the industry to reach the new generations.

The more we can do to create an umbrella of interest and get people excited about what we are doing and have them see that this is a career they can have for 10, 20, 30 years, upon which they can build a life and raise a family, the better. It is so important to have that.

This article was originally published in the Autumn 2022 Bioindustry edition of AFRY Insights.

Bioindustry Management Consulting

To survive and flourish, industries and companies must adapt and innovate at an ever-increasing rate. Our dedicated team of nearly 200 industry experts advise clients across bioeconomy value chains from forestry to packaging and retail, as well as from new bio-based materials to novel new end-uses.