Green gold, digitalised

All companies know that, to run operations efficiently, it is essential to have your facts straight. This applies to forestry as much as, if not more than, any other sector. Imagine any operation where the inventory information has over 20% margin of error, and how that would impact the operations.

For optimal operations and continuous improvements, forestry companies must have real-time visibility and controls in place. When forest source information is accurate, the benefits carry throughout the operations. Precision forestry aims to identify and capture those benefits.

Several areas of benefits

How does an accurate inventory affect operations in a supply chain? To answer this question, we need to look at the operations within it, from planting trees to the end of their life cycle.

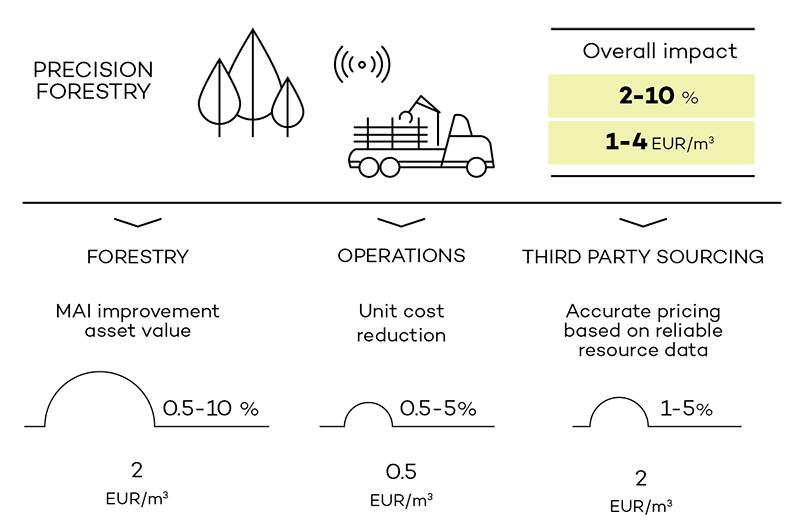

We may identify several areas of opportunity. They may not always be obvious, as operations today are shaped to mitigate inaccuracies in source information, and a large variety of operations and ways of handling assets exist. We may categorise the overarching areas of opportunity to forestry, operations, and sourcing, where the overall benefits may range from 2% to 10% combined of annual cost savings and output increase. Seemingly small improvements, yet in a scale of large forest companies, the impact starts from several million Euros annually, every year.

Gathering the full picture of operational benefits is complex. The benefits run through different operational areas and divisions within the organisation, and thus, the decision making should be at the top of the organisation.

Forestry – increased growth

In forestry, the goal is to grow healthy trees with expected rate to capture and store carbon, as well as to supply for processing of wood and biomass. Tree growth is impacted by multiple variables, such as soil type, weather, nutrients, pests, to name but a few, and the silvicultural management is based on those attributes. If the silvicultural actions were more precise and optimised to each condition, they could produce higher growth and allow earlier detection of possible damages in the forest.

This requires managing optimally sized, accurate, homogeneous sub-environment units. This would also likely reduce e.g. fertiliser, pest control, and use of other materials when directed more accurately. In a plantation environment, the cycle is a lot shorter than in boreal forests, and the effect of actions is faster and more visible. More accurate management of the sub-compartments of the forest will also give a valuable feedback loop to R&D for more optimised clone production.

Overall, accurate inventory information enables smart precision forestry with benefits in operational efficiency and increased growth, measured with Mean Annual Increase (MAI).

Operations – unit cost reduction

Today, operations are planned based on the assumed inventory on the forest. Operations, such as harvesting and related logistics, are a chain where one inaccuracy leads to another and can cause inefficiencies to pile up when things do not go as planned.

For example, the harvesting crew not meeting the volume expectation leads to additional harvesting elsewhere in a less optimal location. As a result, log trucks may run excessive distances empty or with partial load. This is a cost on its own, and a clear inefficiency through the supply chain from forests to mill sites.

Sourcing – accurate pricing

In sourcing, the accurate information of the targeted forest asset removes many variables within the purchasing process. Today’s pricing strategies try to mitigate the risks in procurement to overcome the inaccuracies in valuation. Manual labour dominated sourcing of wood and biomass may be significantly improved through utilising accurate forest asset information, which would allow elimination of manual interference resulting in significant cost savings.

When calculating the effects of a single incident and then applying that calculation to number of incidents on an annual basis, the benefit can be quite significant. Wood sourcing companies are willing to pay more for wood that has less quality and volume variability, as it may increase their competitiveness and efficiency.

How is all this enabled?

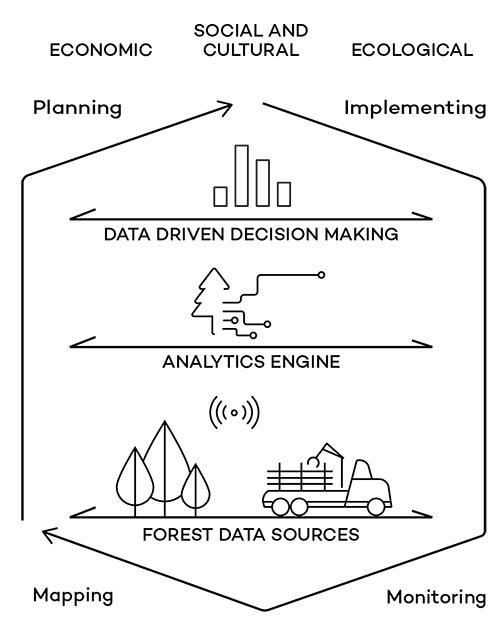

Smart Forestry aims to make technology available to gain benefits. We have touched on major benefits that the technology has to offer, yet how do we do it?

Tree-level digital inventory and monitoring can be achieved with RGB and/or LiDAR sensors in drones today. LiDAR provides very accurate measurement of the tree, and multi- and hyper-spectrum cameras provide colour data to detect different tree species, potential pest or disease damages, and even early detection of pest or disease damages based on colour changes invisible to the human eye. More up-to-date information and early prevention may save large forest areas from damage.

Frequency of forest monitoring determines the accuracy further. With long measurement cycles, the accuracy for growth and detecting potential damages becomes inefficient. With higher frequency, actual growth data can be corrected on each management unit against the growth model, and changes applied to an inventory information. Damage identification and prevention require a higher frequency to stop potential damage on time. Measurement four times a year in a plantation forest environment, and annual frequency in a boreal forest, give significant improvements to accuracy for growth and damage control.

Forest management always uses multi-source data – the art is to use these sources in an efficient way. Satellite data allows detection of larger scale changes, drone sourced tree level data accuracy efficiently, and harvesting data the very truth of the harvested volume. When we combine these data sources in an inventory database, a complete digital twin of forest is created. With the help of Artificial Intelligence (AI) algorithms, the growth may be automatically corrected on each measurement to match similar sub-compartments and areas. The inventory raw data is big and requires sufficient processing to translate the information to a meaningful inventory database that forest management systems may process and utilise.

Planning & optimising for perfection

Forest management is always a matter of planning for years ahead on natural resources that grow at varying rates. Forest management must be carried out according to the desired outcome, with preparedness to make changes along the way. Applying growth models to forest assets is no novelty. However, based on today’s inaccurate source data with an error margin of over 20%, the 5-50-year planning cycle will undoubtedly cause large uncertainties as to the outcome. Whilst forests may be measured on tree-level, the management of the forest assets is not practical on tree-level.

Each plan should be optimised to a smallest reasonable management unit. IoT sensors can be implemented in operational machinery to complement data sources for a further optimisation of operations. Digital inventory enabling simulation and optimisation of forest asset growth and usage provides the most accurate platform for planning, operations, and forest valuations, inclusive of carbon storage. It takes the guessing away from your game regardless of the role in forest utilisation. Smart Forestry gives you the tools and the platform to optimise forest operations, enabling operational efficiency and better preparedness to support forest growth in an optimal way.