How can storage providers improve the resilience of their battery supply chains?

Having highlighted the challenges faced by Europe’s energy battery storage supply chain, we can begin to formulate impactful resilience measures.

‘Traditional’, ‘Alternative’, and ‘Circular’ measures can be implemented in addressing the causes and effects of supply chain vulnerabilities. Together, these actions will help prevent supply chain disruption from impacting batteries’ critical role in the net zero transition.

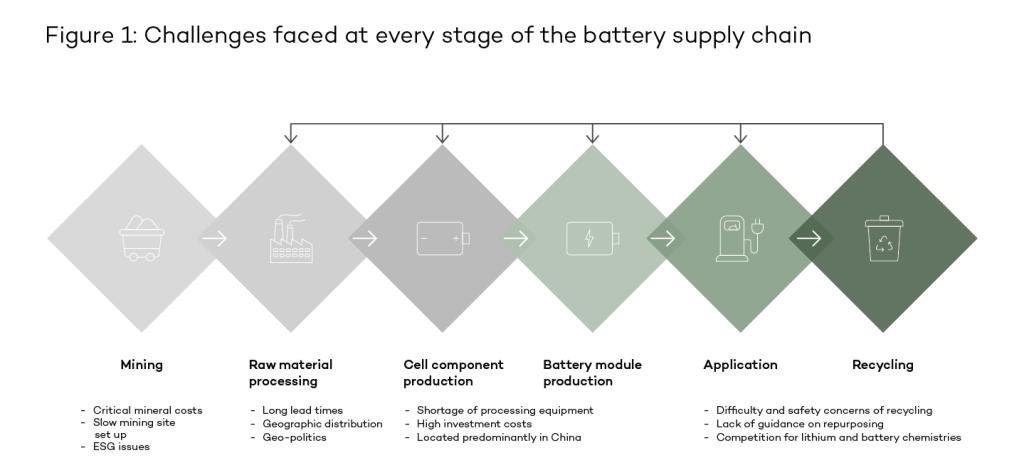

Our previous article on the ‘Vulnerabilities of the Battery Supply-Chain for European Utility Storage Providers’ detailed issues affecting mining, raw material processing, cell and module production, and application, re-using & recycling. These ranged from technical issues such as mine capacity and battery chemistry, to social issues like geo-politics and ESG concerns. Formulating effective measures to respond to these varied pressures will be vital for European utility storage providers

In this article, we have classified resilience measures as ‘Traditional’, such as vertically integrating the supply chain; ‘Alternative’, such as exploring different battery chemistries and emerging grid technologies; and ‘Circular’, employing reuse and repurposing in the battery supply chain. Each of these areas will be considered with examples and proposals of actions by utility providers and electric vehicle manufacturers to increase their resilience.

Traditional measures, such as vertical integration and wider diversity of suppliers, will build up our collective resilience

To ease over-reliance on downstream suppliers, storage providers can look to vertically integrate production. This will help secure critical raw materials and decrease price volatility, either through alliances and partnerships or through targeted acquisitions. Some energy storage providers already aim to work exclusively with sustainable mining companies that follow OECD guidelines. For example, Northvolt does not source cobalt from the DRC and instead utilises integrated suppliers in regions without ‘artisanal mining’ – mining where workers are not officially employed by a mining company undefined .

European and Japanese original equipment manufacturers are also extending their cell components and battery pack production capacity outside China, supporting a reduction in global reliance in the downstream supply chain and encouraging resilience to any potential geo-political issues undefined . For example, suppliers Panasonic, LG Energy Solution, and Samsung SDI have all announced new battery manufacturing plants on the US East Coast undefined . Utility storage providers can also avoid geo-political bottlenecks and wide geographical distribution through engaging with more local suppliers. The US Inflation Reduction Act attempts to increase resiliency of energy storage supply chains primarily by incentivising mineral sourcing from friendly nations undefined . In Europe, Northvolt is planning new gigafactories in Germany and Sweden with the intent to position itself as the EU’s go-to company for home-grown batteries undefined .

Exploring alternative measures, through emerging technologies and chemistries, will lessen our current dependencies

Many new alternative battery chemistries are available, and this diversity may aid the current supply chain’s reliance on a particular mining or processing operation. There are different types of lithium-ion batteries, sodium or zinc ion batteries, vanadium or iron flow batteries, sodium sulphur batteries, and liquid metal batteries undefined . Each of these technologies varies in supply security, performance, and cost effectiveness as shown in Figure 1 undefined . Storage providers could benefit from being aware of not only each chemistry’s strengths and weaknesses, but also the opportunities and vulnerabilities present in each respective supply chain.

Figure 2: Battery Chemistry scored values for supply security, cost-effectiveness, and performance

Investing in intelligent battery management system providers, such as ION Energy, and analysing battery field data using diagnostic solutions providers, such as Volytica, can lead to improvements in battery life and performance. This will reduce the frequency of battery replacement and can act to temper the need for expanded capacity within the supply chain.

The wider battery energy storage sector can also expand, including through use of residential battery storage, centralised grid storage, and vehicle-to-grid infrastructure. The deployment of these technologies will be dependent on technology maturity level, as well as the specific needs of a given locality. Understanding these needs and finding the correct balance of these technologies will help reduce the stress on the battery supply chain, as all these solutions rely on varying battery chemistries.

Supporting circular measures, by recycling and repurposing, offers us the opportunity for a more sustainable and robust supply chain

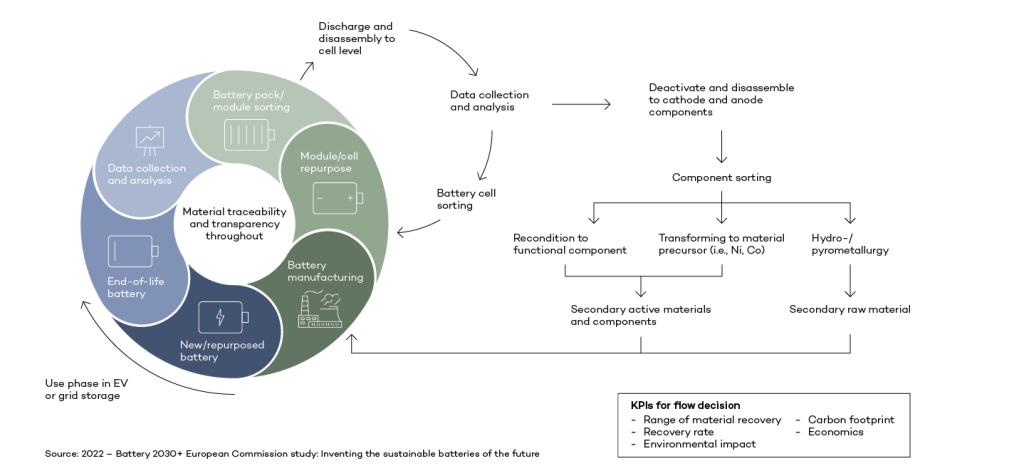

The most impactful of measures to increase resilience, primarily for utility providers, is to focus on improving the circularity of batteries. To account for the growing necessity for battery recycling, many start-ups around the EU have been launched to tackle this challenge 7 . However, achieving circularity in the battery supply chain is not simple, with complex processes required to enable repurposing and recycling. There are many key performance indicators that direct the flow of circular choices and there is currently minimal focus on this area. To enable smoother decision-making, material traceability and transparency is required, from the mining ore quality all the way through to battery end of life. A recent amendment from the EU battery directive stipulates that from 2026, all EV and industrial batteries on the EU market will require a unique battery passport, retrievable using the unique product identifying QR code 8 .

Figure 3: Battery circularity with recycling and re-purposing integrated

What lessons can we learn from the battery supply chain? How can we apply them to other critical net zero technologies?

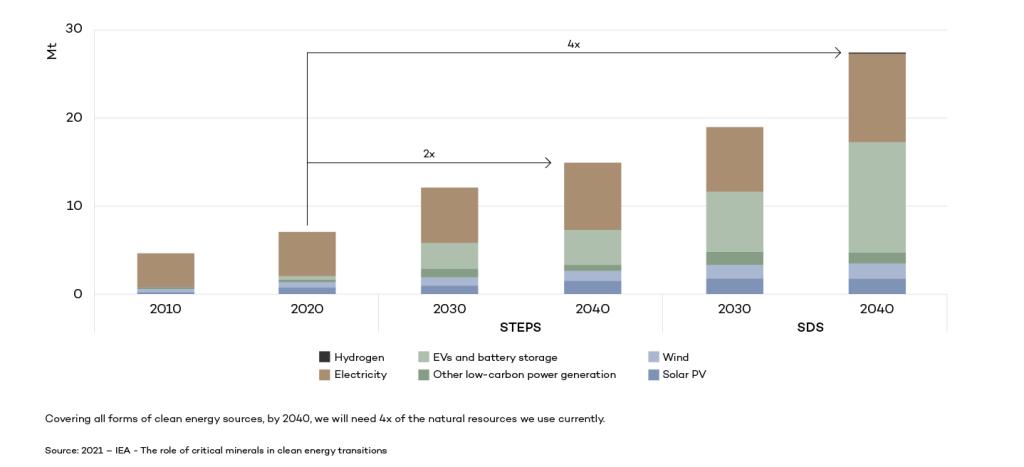

The global transition to clean energy is leading to a significant growth rate of solar panels, wind turbines, and electric vehicles. As the IEA have identified, this is already leading to a rapidly growing market for key minerals which could be subject to price volatility, geopolitical influence, and disruptions to supply 9 . The projected total mineral demand from clean energy technologies by 2040 is set to double in the stated policies scenario and quadruple in the sustainable development scenario undefined .

Figure 4: Total mineral demand in 2030 and 2040 in STEPS and SDS scenarios

Large uncertainties around possible futures may cause supply-demand imbalances in the years ahead and analysing not only the battery supply chain, but all clean energy supply chains, will be critical. By doing so as early as possible, we can collectively invest and legislate for targeted resilience measures that best support a secure and dependable net zero transition.

On-demand webinar: Exploring the Utility Storage Battery Supply Chain

Footnotes

- undefined. //www.datocms-assets.com/38709/1655449087-northvolt-sustainability-report-2021.pdf a↩ b↩ c↩ d↩ e↩ f↩ g↩ h↩

- 7. //www.pem.rwth-aachen.de/global/show_document.asp?id=aaaaaaaabpjuwfj a↩

- 8. //battery2030.eu/wp-content/uploads/2022/07/BATTERY-2030-Roadmap_Revision_FINAL.pdf a↩

- 9. //iea.blob.core.windows.net/assets/ffd2a83b-8c30-4e9d-980a-52b6d9a86fdc/TheRoleofCriticalMineralsinCleanEnergyTransitions.pdf a↩