Path to decarbonisation

Small Modular Reactors (SMR) - part of the solution?

The energy sector is responsible for three-quarters of global emissions therefore 'decarbonising' this segment has become a top priority (20% of energy consumed globally is in the form of electricity - the remaining 80% comes directly from fuels used for heating, transport, industry). The UN targets a 45% reduction in emissions by 2030 and net zero carbon emissions by 2050 to limit rising temperatures, however current projections have emissions increasing 14% by 2030. In addition, the Russia-Ukraine conflict has highlighted the fragility of certain parts of the global energy system and resulted in volatile energy prices. Understandably, when looking for a solution, much focus is on renewables - especially wind and solar - but there are challenges to overcome in order to fully replace fossil fuel power production owing to their intermittent energy output profile depending on prevailing weather conditions. Whilst it is technically possible to overcome this challenge with energy storage and other flexibility measures, a low carbon baseload power will still be required to support a decarbonised grid.

Nuclear energy is the second-largest low-carbon power source, making up 10% of 'green' electricity globally and 40% amongst developed nations, however the technology continues to suffer from bad-press, from some quarters, associated with legacy waste, historical accidents involving old designs and concerns over safety.

Conventional (large-scale) nuclear power plants are expensive and time-consuming to build, making financing a challenge - this, along with the concerns and challenges mentioned above are often the reasons why this technology is not more widely deployed.

The nuclear industry has been required to rethink and adapt to the increasing demand for clean energy and to overcome the challenges of its large-scale projects.

A new class of reactor is being developed to tackle these issues - the Small Modular Reactor (SMR):

- Small: SMRs are a fraction of the size of a conventional nuclear power reactor (think under one football pitch for the smallest designs and up to 7 football pitches for the largest of the proposed designs), making them versatile for deployment.

- Modular: making it possible for systems and components to be factory-assembled and transported as a unit to a location for installation.

- Reactor: using power-dense fuel to undergo nuclear fission (the splitting of an atom to create energy) to generate energy in the form of electricity or heat.

The smallest SMR "micro-reactors" proposed offer 1MW power whereas larger SMR designs provide up to 440MW, which is approximately one third of a traditional large reactor (An SMR is generally limited to a power output of under 300MW, however some proposed designs exceed this and are still classified as "small"). This variety of designs being developed will provide a flexible solution to decarbonisation across many geographies and market sectors.

As well as providing secure and stable electricity and heat, SMRs can complement the increased deployment of renewable technology. The intermittent nature of wind and solar power requires energy storage solutions or other grid stabilisation and management methods. Nuclear reactors can, within certain limits, match output to demand "load-following" characteristic) - increasing output during renewable intermittent periods and reducing when renewable production peaks; thus improving the resilience of the overall power system. Depending on the overall plant and auxiliary system design, SMRs can also provide power for hydrogen production and/or desalination which provides additional flexibility and benefit in the drive for wider decarbonisation.

An SMR plant would occupy an area roughly 100 times smaller than a wind or solar farm of the same installed capacity therefore can be located closer to energy demand. This high power-density characteristic of nuclear power can provide particular benefit to remote communities, such as those in Canada and Siberia, who mostly rely on diesel generators for heat and power and where SMRs would help reduce emissions and offer a more economic energy solution. Compact, air-transportable designs fit for this purpose are being developed, with decade-long lifetimes. NASA is even testing a two metre tall SMR for space missions.

Many western vendor programmes have first-of-a-kind units and commercial deployment planned for the late 2020s or early 2030s, however the first commercial SMR is already under construction in China. It should also be noted that SMR type designs are used in military ships and submarines, safely operating under challenging conditions for over 65 years.

There are some challenges still to overcome so the journey from large-scale nuclear to SMRs requires innovative solutions for:

- Construction times for conventional nuclear power plants is on average 7.5 years and total project lifecycles can be over a decade from first concept to commissioning. Delays are notoriously common in large projects and lead to wildly inflated budgets, such as at Hinkley Point C in the United Kingdom - currently delayed by a decade and projected to be £7 billion over budget. SMRs are designed for modular, factory fabrication which eliminates the majority of on-site activity, thus significantly shortening construction times. In addition, the repeatability associated with using the same design for multiple plants reduces risk and minimises delays.

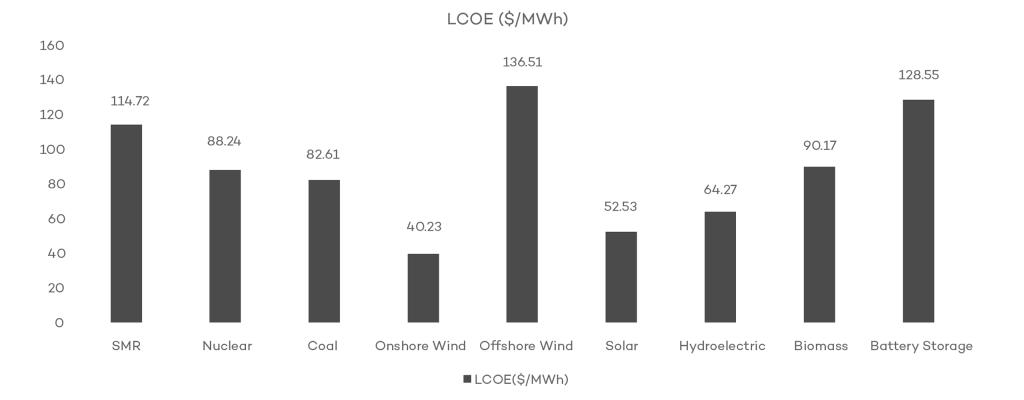

- The 'Levelised Cost Of Energy' (LCOE), usually expressed in $/MWh, is a measure of the average cost to produce energy for a given plant over its lifetime, accounting for all costs. A "one-off" SMR could not match the LCOE of conventional reactors, which follow 'economies of scale' - meaning that bigger reactors are more cost efficient. SMRs instead rely on 'economies of series' whereby costs are driven down by high volume factory production. They could also be built at retired fossil fuel plants to repurpose existing generator and transmission equipment, for further savings, or on decommissioned nuclear sites.

- Safety is always a key priority in any energy project but of particular importance to the nuclear industry. SMRs are able to benefit from passive safety systems which, while also found in modern large-scale reactors, are easier to implement in SMRs because of their size. These are design characteristics and safety systems that do not require external power, monitoring or human intervention to ensure the safe operation and shutdown of the reactor. Some SMR designs rely only on passive safety, eliminating the need for operators. SMRs can also be installed underground, providing additional security against natural disasters and malintent.

- Licensing and regulatory approval of nuclear facilities takes time, however various international initiatives are ongoing to share information between regulators, with the aim of standardising the process where possible. This will facilitate international rollout of designs and increase the benefit from mass modular production.

The innovative SMR designs being proposed, coupled with the knowledge obtained from the last 70 years of nuclear power as well as improved processing and final solutions for nuclear waste, mean nuclear technology can provide a robust contribution to decarbonising the energy and industrial sectors.

With intelligent application and deployment, SMRs can provide low carbon energy as well as support greater and faster rollout of renewable technology in a cost effective manner. So, as various SMR designs are progressed and pass through the required legislative and regulatory processes worldwide, it is now time to rethink and adapt to nuclear being part of the solution.