Process simulation and modelling improves productivity

In modern design, a plant’s simulation model is used as the “digital twin” of a plant. Adding process modelling as part of the digital twin concept will help to achieve more accurate results, optimise processes and keep changes under control at different project stages. This benefits the plant and the clients directly.

A digital process model can include data about the operations and conditions of a real plant and it can show the impact of planned changes on plant operations in real time. For example, a dynamic model helps to examine the start-up and shutdown stages of a plant and predict behaviour in the case of emergencies or failures. Modelling speeds up the design process in a cost-efficient and safe way. It also helps to control the entire lifecycle of a plant

The aim of process optimisation is to improve the availability of a plant, the efficiency of investments, and the safety and energy-efficiency of operations. Another goal is to minimise environmental impact. The role of modelling and skilled modelling engineers is emphasised when competition is fierce – when it is necessary to be efficient while at the same time staying on schedule and on budget.

A simulation model can save thousands of tons of material, megawatts of energy and millions of euros in costs and lost income. Using a simulation model, the safety of a new process can be improved by focusing on the physical and chemical properties of the process. Once it has been identified how a process behaves, there are no surprises and risks can be minimised. It is also important to prepare a simulation model for a standard process, as it improves the workflow.

A simulation model adapts to changes

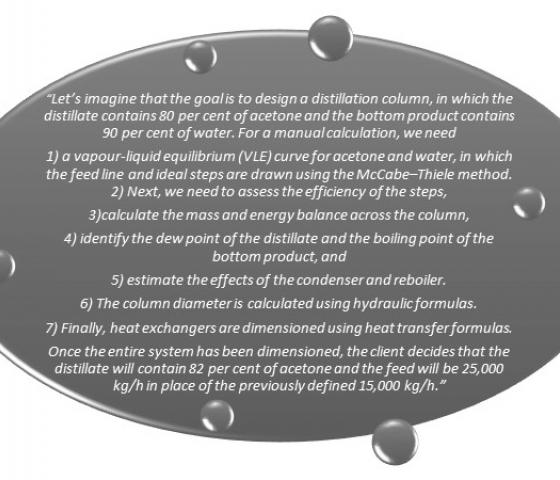

There is no project or process that does not need changes at some point. The following example describes the complexity of unit operation models and the changes faced during the design process.

Using a simulation model, above explained change can be calculated in no time. All the complete model needs is a little fine-tuning. In these types of assignments, the use of a simulation model is a superior option compared to the use of conventional calculation methods. Even minor changes can have a significant impact on results, and they are remarkably quicker and easier to calculate using a simulation model. Today, process design remains inadequate without comprehensive simulations and an engineer who is competent in using software.

For example, it would be difficult to assess the functionality of existing process equipment in a new operating environment without simulations. There are highly advanced and comprehensive modelling programs e.g. for heat exchangers. Using these, it is possible to build a model of existing equipment and even carry out troubleshooting.

Benefits for many sectors

Simulation software developers originally built their models for a particular sector or process. However, as unit operations are similar throughout the industry, software was developed to be universal. Common process simulation software includes AspenPlus/HYSYS, ProSim, ChemCAD and Pro II. All simulation tools are based on a mass and energy balance solution, in addition to which results include equipment dimensions, flow-based results, physical properties of different substances, consumption figures and cost estimates.

Modelling is used in many different industrial sectors, such as the hydrocarbon industry, heavy chemical industry and food industry. Unit operations, including reactors, distillation, extraction, filtration and heat transfer, follow the same laws of physics, regardless of the sector. What is more, the comprehensive material libraries of modelling software, based on decades of scientific research, enable the large-scale use of the software.

A modern process engineer is competent in process design and simulation software

When it comes to process design, it is no longer enough that the solution is correct; it must be the best to benefit client needs in all aspects. This solution cannot be formed without a simulation tool and a skilled modelling engineer. The current trend is to get the most out of a plant and its processes. Maximum efficiency and optimised processes are always the primary goals. Simulation modelling helps to produce added value for clients and to improve productivity. In projects, correct results from the clients’ points of view are vital. By producing reliable results more quickly and using optimal resources, it is possible to ensure that projects remain on schedule and budget.

Process Simulation:

- Model of a production plant in software that through mathematic formulas replicates the physical, chemical and other phenomena in the unit operations.

- Solves mass and heat balances with phase separation, chemical reactions and hydraulics through physical properties of pure components and mixtures, reactions and mathematic models.

- Is applied mainly in hydrocarbon industry, chemical industry and food industry as well as in water and wastewater treatment plants.

Read more about dynamic modeling of wastewater treatment plants.