Smelting furnace electrical characteristics and effect on the electric grid

Electric smelting furnaces are one of the key technologies in the metal industries, where they are used, for example, to extract valuable metals from beneficiated ores.

Electric furnaces can reduce CO2 emissions significantly by replacing unit processes that use fossil-based energy for smelting. The furnace characteristics, e.g. power level and its fluctuation, are defined by the purpose they are designed for. In addition, there can be big variations between these characteristics. This variety also sets the scene for electrical grid disturbances. The combined understanding of metallurgy and electrification – how the furnace operation is linked with the electric grid quality – is a key feature when selecting the optimal furnace systems.

In industrial use, electric furnaces are economical when there is enough reliable and stable supply of electricity at a competitive price available with a well-working electrical grid.

In the big picture, the smelter operations create disturbances in electrical grids, especially when a high amount of electrical power is required to perform the process operations. The operational mode of the process dictates the level of electric grid disturbances and the required investments to the grid compensation.

Special requirements of feed materials required on an early stage

As a result of resource scarcity, the feed materials, too, are getting incrementally more challenging. Good quality and easily utilized resources are getting depleted. This together with a possible distant location from the main grid places a higher priority on the requirements for smelting furnace operations and effects to electrical grids. This whole process needs to be studied early in the investment development phases, as well as during project implementation to avoid the furnace disturbances becoming too heavy and resulting in exceeding electrical grid requirements. This may lead to financial penalties, production losses, and problems with other plant equipment, as well as issues for other grid clients and eventually for electricity producers. Moreover, technologies that mitigate electrical disturbances have developed further in recent years, especially for the high voltage operations.

The smelting furnace characteristics

The smelting furnace characteristics and the selection of the operation mode are defined mostly by the characteristics of the feed material, slag properties and operation purpose. The smelting furnaces, in this case electric arc furnaces, extract elements at high temperatures. At the same time, chemical reactions occur, such as reduction of oxides to metals. Molten metal and slag are separated inside the furnace due to their density differences. The electrical energy to the furnace is provided via carbon-based electrode(s).

The operation mode of the furnace can be immersed, open arc, shielded arc or submerged arc defined by the position of the electrode inside the furnace. These different modes can be roughly separated into 1) high current (immersed and submerged arc) and 2) high voltage (open arc and shielded arc) operations.

The furnace operation with immersed and submerged arc operation (low voltage, low resistance, high current, no arcing) is very stable with low amount of power swings. The electrodes are in an electrically-stable position inside the furnace.

The high voltage (high resistance, low current, long arc) arcing operation modes create the most unstable conditions inside the furnace, and also most disturbances to the grid. This is a result of the instability of the electric arc formed between the electrode and molten slag. Small changes in the conditions inside the furnace have a great impact on the arc, causing drastic changes in electrical behavior.

Therefore, the effects and disturbances to the electrical grid are dictated by the required operation mode. Based on the electrical grid requirements, various Capex intensive technologies are used to mitigate the grid disturbances.

In the case of immersed and submerged arc modes, only harmonic filter banks are adequate to handle grid disturbances caused by reactive power. In shielded arc and open arc operations, the following systems are used: SVC or Statcom for grid disturbance handling. The above-mentioned technologies are used to handle the grid disturbances, whereas the following technologies are used on the furnace side for direct furnace arc / power stabilization i.e. SPLC / gradator / series reactor systems / DC technology for furnace.

Five principles establish a solid foundation for predictable furnace behavior

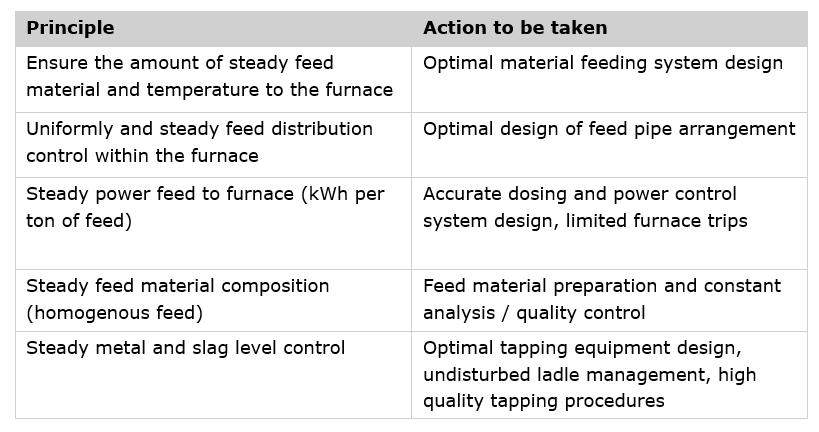

Everything starts from the core process, in this case high temperature smelting operations with chemical reactions taking place. To facilitate as smooth as possible process and consequently the most limited disturbances to the grid, the following principles should be followed in design and operation:

When the above-mentioned principles, that is, the foundations for predictable furnace behavior, are addressed, the smoothest possible operation can be achieved. In addition, the most suitable furnace power / arc stabilization system should be applied, and the correct grid compensation method should be developed.

Seeing the big picture

The combined understanding of metallurgy and electrification – how the furnace operation is bound to grid quality – is a key feature when selecting the systems that are fit for purpose.

AFRY’s pyrometallurgists together with process and electrification experts can provide expertise in designing smelting furnace processes and grid compensation systems. AFRY has a wide, global ecosystem with key technology suppliers in many technological sectors. As an independent consultant, we do independent evaluations for technology selection in all project development phases.

Should you have questions regarding electrical smelting technologies or grid systems, please do not hesitate to contact AFRY experts: