Stitching fashion with the thread of sustainability

Clothing was once seen as a necessity that shielded us from the elements. Today the clothing we wear is seen as a form of self-expression. What we wear is who we are. In the last 15 years, the production of clothing has more than doubled, but the number of times we wear our clothing has seen a dramatic decline.

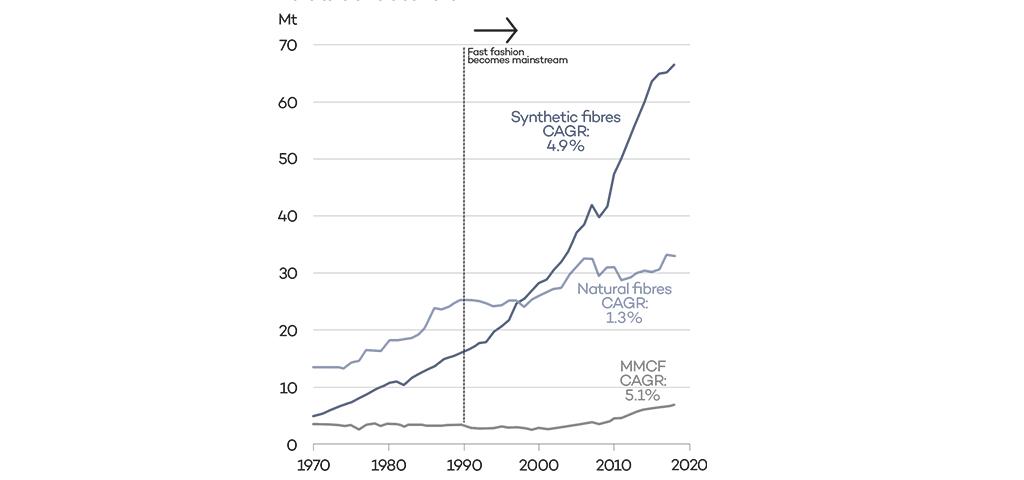

It was three decades ago when low-cost, fast fashion propelled into mainstream. Its catalyst? Synthetic fibres. Retailers started to market numerous “micro-seasons” in order to boost sales. Manufactured quickly and on a tight budget, these items of clothing are usually not made to last, and “cheap” ultimately comes at a cost not borne by the consumer. In a given year, more than half of the fast fashion produced is disposed of, and three quarters of all clothing made globally either ends up in a landfill or is incinerated. Looking fashionable isn’t looking very good.

In more recent years, consumers have become more aware of the environmental impact of their wardrobe. With their buying power, consumers are exerting pressure on the fashion industry to improve its environmental footprint and commit to more sustainable practices.

This is changing the way brand owners and retailers operate and impacting the rest of the textile value chain too. There is more emphasis on establishing sustainable textile fibre procurement practices, environmental labelling as well as adherence to multiple certification schemes. And the most recent focus? Recycling of textile fibres and sustainable fibre production.

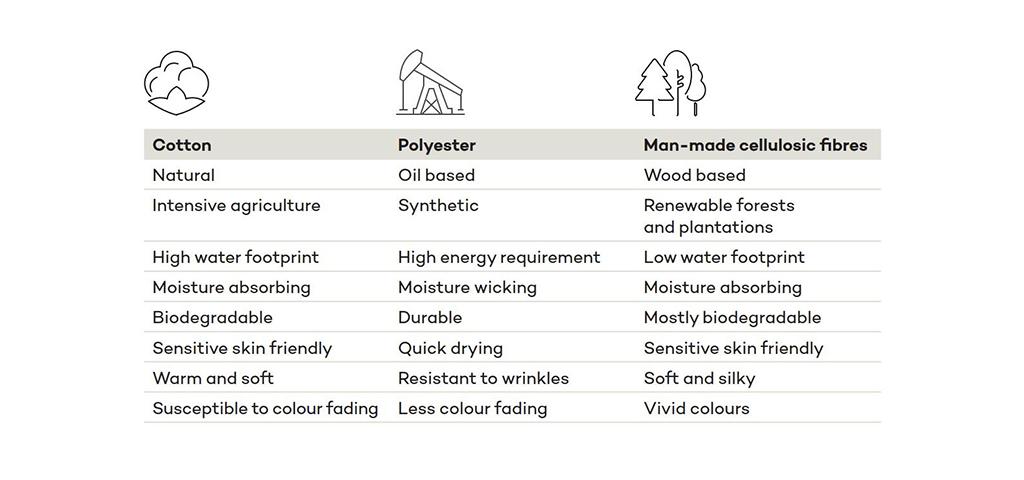

But classifying and quantifying which fibres are more sustainable than others is no straightforward task. Is cotton more sustainable than polyester? What about semi-synthetic fibres? It gets a bit tricky.

Historically, natural fibres such as cotton were the dominant type of fibre used for textiles. But cotton requires arable land which could otherwise be used for food production. In addition, cotton is also a water intensive crop sensitive to its environment. With that in mind, it is unsurprising that the production of cotton has not increased much since the late 1980s. The marginal increase that we do see is attributed to increases in yield and genetic modification. However, the use of GMO is not accepted by many and it is only organic cotton that is gaining market share.

Today, the most common type of fibres used in textiles are synthetic fibres, in particular polyester. Although polyester is comparatively inexpensive and durable, its major drawback is that it is oil-based. According to Forbes, nearly 70 million barrels of oil are used each year to produce polyester around the world. And should your polyester T-shirt end up in a landfill, it will take more than 200 years to decompose.

In the last decade, the production of semi-synthetic man-made cellulosic fibres (MMCFs) such as viscose and lyocell, have considerably increased. MMCFs are predominately made from trees that do not require arable land and have a low water footprint. Moreover, MMCFs are not oil-based and are mosty biodegradable. These fibres offer the fashion industry a viable option in the quest for more sustainable solutions.

Having said that, more solutions are emerging. Like novel textile fibres which are produced using alternative feedstocks or with improved processes. Some even have enhanced functionality. Perhaps you have already come across items of clothing made from plastic PET bottles, agricultural waste or even an old pair of jeans? Indeed, the fashion industry is undergoing a transformation - from its traditional linear system towards a circular economy.

Although the majority of novel textile fibres are still in early stages of development, commercialisation is accelerated by partnerships in the value chain. Typically, these partnerships are between novel textile fibre producers, usually start-ups, and well-established, global brand owners. It comes as no surprise then that industry players such as Aditya Birla, Lenzing, Metsä Fibre, Sateri, Södra and Suzano, are taking note, and more importantly, taking action. All are hard at work developing fibres for threads that will stitch the fashion industry towards sustainability.

At AFRY Management Consulting, we could help you spin your fibres into this much-needed thread. We support our clients in identifying business opportunities across the textile value chain. We are particularly active in assessing the maturity of novel textile fibre technologies, in modelling the competitiveness of MMCFs vis-à-vis other fibres, and in discussion with brand owners on their renewable textile fibre needs.

One last thought. Have a look at what treasures you have in your closet. When the lockdown hit earlier this year, I finally got around to sorting out my closets. Hanging, fifth from the left, was a denim shirt which my mother bought me when I was still in primary school. The tag reads, “100% cotton, Age 13”. And right next to this shirt, my new favourite dress. And its tag reads, “100% lyocell (TENCEL)”.