Switzerland - pioneering in micropollutants removal from wastewater

The Schönau wastewater treatment plant (WWTP) of the GVRZ (Gewässerschutzverband der Region Zugersee-Küssnachtersee-Ägerisee, Zugersee-Küssnachtersee-Ägerisee Region Water Protection Association) treats the wastewater of 14 municipalities in Central Switzerland. With its current population of 150,000, this is one of Switzerland’s largest wastewater treatment plants and makes an important contribution to prevention of water pollution in the region.

With the introduction of new water conservation legislation in 2016, around 120 wastewater treatment plants are to be equipped with the latest technology in order to eliminate organic trace substances and micropollutants which are present in very low concentrations in wastewater. These include substances such as drug residues, pesticides and corrosion inhibitors, but also chemicals from personal care products which have proven to have adverse effects on aquatic life and endanger groundwater as the most important source of drinking water. Switzerland has taken on a pioneering role in this regard and has created both legal and scientific foundations. The objective is to eliminate more than 80% of micropollutants at around 120 wastewater treatment plants in Switzerland. The federal government has launched a fund so as not to unfairly disadvantage the specified wastewater treatment plants and the residents connected to them. Every Swiss resident will pay an annual contribution of CHF 9 to this fund until 2034. The money will be used to provide up to 75% of the financial support needed for investments in the wastewater treatment plants, which are obliged to eliminate micropollutants. The connected residents will be exempted from this charge as soon as a plant has built a new treatment stage and the stage is up and running.

The expansion of the Schönau wastewater treatment plant with a stage for elimination of micropollutants was planned and implemented by Pöyry Schweiz AG, which operated as the general planner between early 2016 and mid 2019. With the timely submission of the final statement to the Federal Office for the Environment (FOEN), the mandate is close to completion.

Space was severely limited, and the expansion work – which involved a large number of different objects – included costly construction at and between the existing infrastructures. Solutions for integration of the new process stage were devised by converting and adapting the existing structures. The core parts of the plant (such as the return sludge pumping station) were converted and relocated while the plant was operational. Despite being extended by an additional level, the area of the wastewater treatment plant was not enlarged, but concentrated internally in particular.

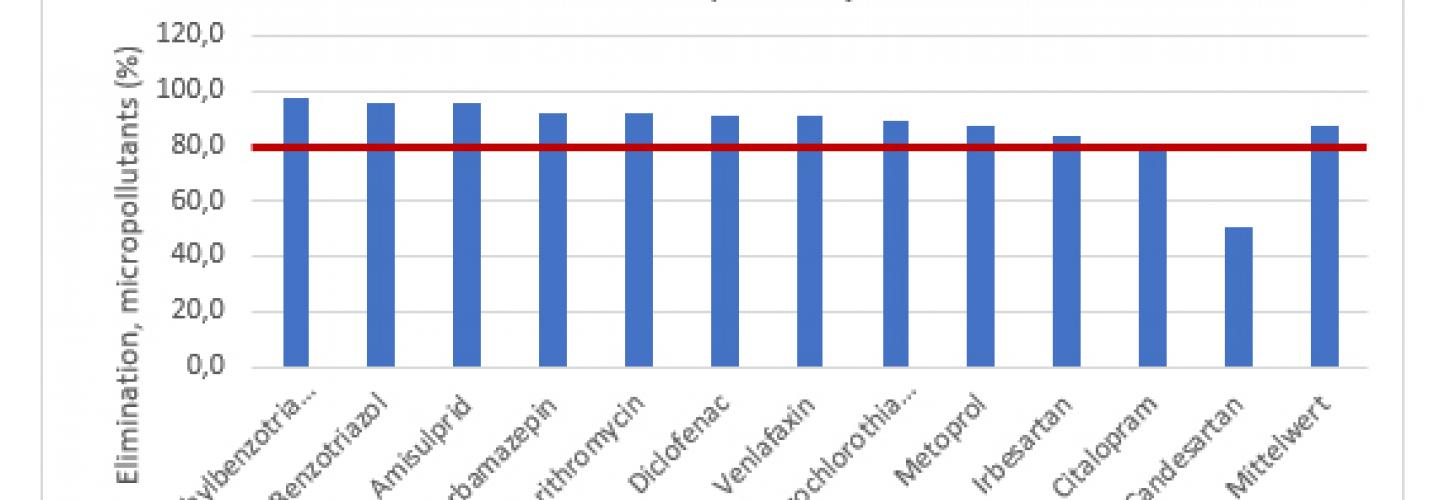

The process stage implemented – with the dosing of powdered activated carbon (PAC), mixing this into the wastewater and separation by means of tertiary filtration – represents the first large-scale implementation of this technology anywhere in the world. The PAC direct dosing technology selected rules out production of hazardous, toxic by-products that can be generated by other process technologies employed, such as wastewater ozonation, and offers a high degree of operational flexibility. After almost a year of trials, the plant operator is very pleased with the new installations and the treatment performance achieved. The elimination rates required by law can be met with a large margin and without problems (average elimination rate > 80%). The dosages of powdered activated carbon required to achieve the specified elimination rate are even lower than originally predicted by means of pilot testing. The further optimisations implemented during the project have also significantly improved the performance of the biological treatment stage.

Besides the engineering expertise and professional project management, adherence to quality, deadlines and costs was the primary reason for the high level of customer satisfaction.

AFRY (Pöyry Schweiz AG) is currently planning further micropollutant elimination stages at Swiss wastewater treatment plants Aire Geneva (1,000,000 p.e.), Bern (500,000 p.e.), Monthey-Cimo (500,000 p.e.), Kloten-Opfikon (125,000 p.e.), Rosenbergsau (110,000 p.e.), Lucens (70,000 p.e.), Delémont (50,000 p.e.) and Hinwil (30,000 p.e.).

The issue of organic trace substances is a key element in future wastewater technology in Germany, too. Close cooperation with AFRY’s experts has made it possible to start working with the technology, and projects are being planned for wastewater treatment plants in Berlin Schönerlinde (850,000 p.e.), Herford and Münster.