Textile Recycling: Drivers & Challenges

The traditional textile and fashion industry has been built on the delusion that the resources of raw materials are limitless. Currently, it is the second most polluting industry, producing 1.2 billion tons of CO2 equivalent per year. The fashion industry follows a non-circular model. This model does not meet the demand of the new generation of aware consumers. This social awareness with other environmental sustainability crises had led to the development of new legislation and directives. These crises and legislations have moved society to investigate the business models which can lead to a circular economy where waste is not being produced in the manufacturing loop.

How to make textile industry more sustainable?

Textile industry produces the waste by several means such as: wastewater, waste chemicals (dyes and finishes), fertilizers and pesticides used for production of natural fibres and last but not least fabric and fibre wastes. Thus, any revision in the whole value chain which moves this industry toward a sustainable and environmentally friendly one is invaluable.

One approach to address the resource efficiency in connection to the waste, water and energy managements is recycling/upcycling of the waste textile fibres and fabrics which can contribute to closing the loop. European Commissions’ Circular Economy Action Plan will be a key driver in encouraging circular economy in Europe in the coming years. According to the Waste Frame Directive, EU Member States will be obliged to arrange to separate the collection of textile wastes from 2025 and the guidelines are under development.

Currently, several start-up companies like Re:newcell, Worn Again, and SaXcell with pull from brand owners like H&M, IKEA and push from raw material and fibre suppliers such as Södra and Lenzing are actively investing and working on recycling of the pre- or post-consumer waste textiles.

The main challenges of textile recycling

Polyester and cotton are having the main market share of the textile fibres, constituting 52% and 23% respectively. In principle, chemical recycling of the polyester is well established, but for natural fibres like cotton it is at its inception stage.

However, there are some significant challenges which need to be addressed and can be categorized as follow:

- Sorting: The sorting and separation of the different fibre types from each other and from impurities such as zippers, buttons, etc.

- Sourcing: Lack of systematic and efficient sourcing of waste textiles for the recycling technology developers.

- Heterogeneity of the waste textiles: Heterogeneity of the waste material in terms of different histories of each fabric, presence of dyes, finishes and other chemicals in the material which make the full recycling if not impossible, highly demanding, adding more steps to the process and affect the final properties of the final product.

- Downcycling: The quality of the re-produced material will be lower than its equal product made by virgin raw material, therefore if not used as low-quality product it often needs to be mixed with some virgin material to be able to make a final product acceptable in the market.

- Geographical difference of manufacturing and consumer market: The new legislations, directives, new technologies and a big part of consumer market are in EU and US, however the main manufacturing sites are in Southeast Asia.

According to the first principle of “Green Chemistry”, it is better to prevent waste than to treat or clean up waste after it has been created; this should be the long-term objective for the textile industry. To reach this target all the actors in the whole value chain of textiles should collaborate and establish strategies of waste reduction (e.g., facilitating recyclability), and provide proper support to the innovation, research, and development work on the processes capable of upcycling the waste textiles, dyes and other chemicals present in the product. In the meanwhile, the development of guidelines for textile waste handling by the policymakers would be highly beneficial.

Evidence of increasing interest

The interest is there, and some big textile and fashion brands and retailers together with new tech companies have already reacted to the EU Sustainable Products Initiative by developing processes for recycling of waste textiles.

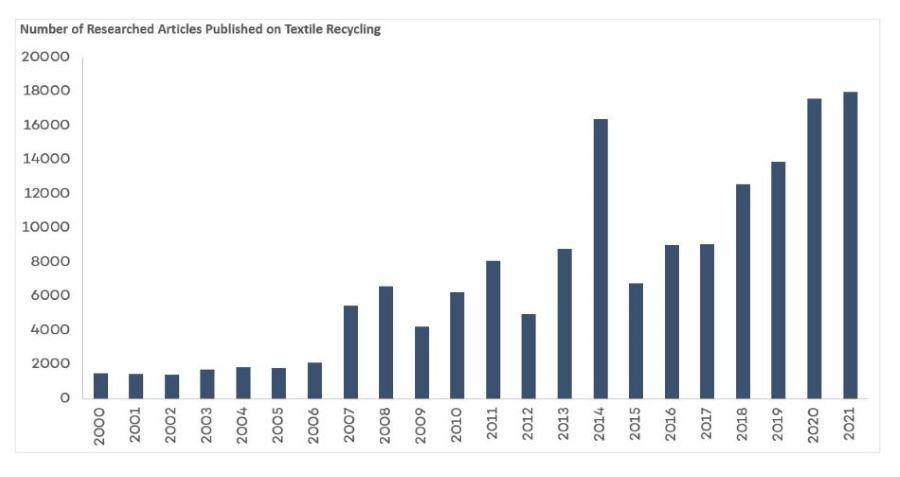

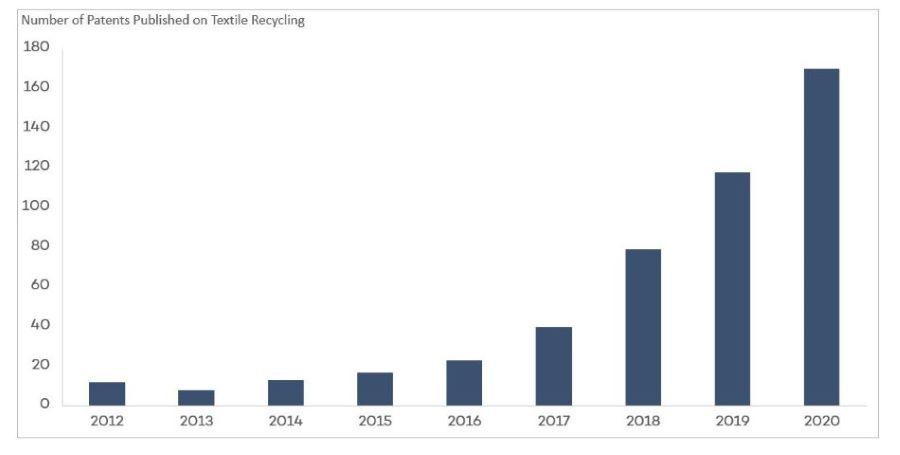

The importance of textile recycling is also noticeable by the significant increase in the number of publications on the “Textile Recycling” in scientific journals and patents in recent years. These statistics show that textile recycling development is proceeding and probably some new technologies will be commercialized in the upcoming years.

AFRY can support from innovation to commercial scale production – and in everything between

At AFRY we have several successful projects in upscaling the emerging textile technologies in textile recycling and greener textile fiber production processes. We offer services from concepts developments to implementation by joining our knowledge from management consultancy and engineering teams. At AFRY Process and bio industries, we have the know-how knowledge, management and engineering tools needed to develop and scale-up the processes you are working with. We can help you to tackle the challenges you may face during the research and development or scale-up phase to reach the market and adapt to the new business models.

This article is written by:

Magnus Hörnsten, Process Consultant, AFRY Pulp & Paper industry Sweden