Tomorrow’s design of hospital ventilation

How Computational Fluid Dynamics (CFD) simulations may be used to analyse how different ventilation solutions will reduce the amount of pathogens in the air and thereby decrease spread of infection.

As late as January 13, 2020 The world health organization (WHO) listed thirteen challenges that is considered urgent for the next decade . Two of the challenges are linked to the health care systems and the people that work there. According to WHO, a significant investment is needed during the coming decade for improving the competence and working environment within the health care system.

AFRY is a strong partner in the development of new - and improvement of existing -hospitals. With numerous large projects in this sector in its reference portfolio, AFRY is prepared to aid the authorities with the challenges. A natural step in this development is the ability to track emissions of pathogens to the air in the building using advanced fluid dynamics simulations.

Here, AFRY has a unique capability because of a world class Computer Aided Engineering (CAE) department that is capable of conducting these simulations. The advanced fluid dynamics simulations are commonly denoted CFD-simulations where CFD stands for computational fluid dynamics. With these simulations it is possible to analyse how the air is affected if a patient sneezes or coughs into the air and how the pathogens are transported into the air. The droplets that may carry the pathogens will also to some extent evaporate. Thus, their ability to stay floating in the air will thereby be significantly enhanced. If the pathogens stay longer floating the air the risk of spreading disease will increase.

Three cases investigated

In this short article we present one example on how CFD-simulations may be used for analysing how different solutions will reduce the number of pathogens in the air. In the particular case that this article covers, the patient coughs through the mouth without any cover into the air. It should be noted that the modelling may be altered to cover other forms, such as sneezing, of pathogen emissions.

The actual simulations involve a large amount of physical modelling. The things that need to be considered are for instance the following:

- How large are the droplets emitted from the cough and in what velocity do they travel with, from the mouth?

- How does the droplets evaporate?

- How is the surrounding air affected by the impulse of the cough and the elevated temperature of the coughed air?

This information is combined with the knowledge on turbulence, air movement, ventilation and the 3D-geometry of the room in order to obtain a complete model.

In total, three cases where investigated. Two cases cover the patient laying in hospital bed on the back. For the final case, the patient is laying on the stomach. For two cases, a standard air extractor is used for collecting the pathogens from the cough.

The purpose is to investigate the effect of the point extractor and how the placement of the extractor may alter the reduction of pathogens in the air. It is of special interest that the amount of pathogens around the health care worker is kept as low as possible.

The animations show the real time flow of droplets emitted from a cough. When the droplets are colored blue it represents a droplet size that is found in an aerosol. Thus, the droplets will float with the movements of the surrounding air.

Virtual prototyping

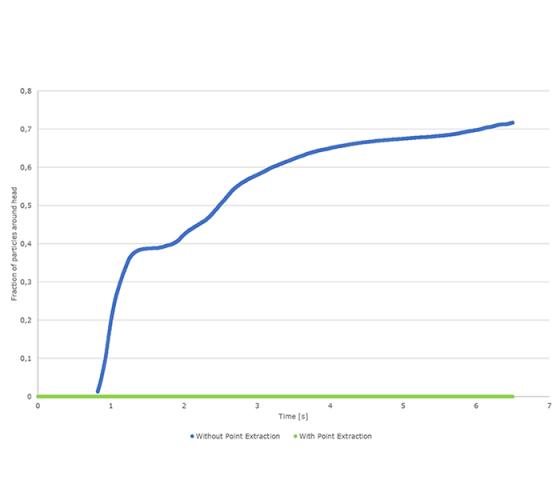

The animations show a significant reduction of particles/droplets around the head of the health care worker. This is further analysed by counting the amount of droplets around the of the worker as a function time. The result is given in the diagram to the left.

The diagram shows that after 3 seconds more than 60 percent of the emitted droplets stay around the head if the point extractor is not installed. In the case of using appoint extractor no droplets were found around the head of the worker. The final analysis with the patient on laying on the stomach shows that further work would be required in finding a better position for the point extractor. This is commonly denoted virtual prototyping. The virtual prototyping is a time and cost-effective way to obtain answers from what if analysis. The virtual prototyping may also conclude that the bowl on the point extractor may be redesigned in order to improve the robustness of the point source extractor.

The results obtained from the virtual prototyping in a real-life case may be used for practical guide lines and education of the health care workers.