Towards a proactive safety culture through visualization of risk assessment

The risk analysis identifies the risk, followed by an assessment of what could happen at worst.

After assessing the magnitude of the risk, the necessary safeguards and measures to prevent potential accidents and minimize their consequences will be defined.

Companies carry out risk management work not only to fulfill regulatory obligations but also to ensure the safety of their own operations. Significant policies are often made in companies based on deviations observed in the risk assessment. These policies sometimes also involve substantial investment. In risk management work, the details of reporting are extremely important to target corrective actions and investments. The preparation of a risk assessment report and the interpretation of the results can be very demanding and require a wide range of expertise as well as good co-operation between the different parties (e.g. engineering, maintenance and operators). Therefore, companies have studied various methods for improving risk management and used so-called risk management methodological expertise.

It is important to evaluate the results of the risk assessment in order to be able to prepare properly for significant risks. However, risk assessment and outcome always include the subjective views of the team. Within a team, views may differ, for example, on the significance of safeguards. In support of the risk assessment, it would also be useful to obtain, if necessary, assessments from experts outside the original risk assessment team as to where the effects of the accident could lead at worst. In this way, better means of preparation can also be identified.

Different risk analysis methods are suitable for different situations

Risk assessment method HAZID (Hazard identification) or HAZSCAN (Hazardous Scenario Analysis) are best suited for project initial phases, where people are identifying the most significant hazards as well as issues affecting the design. The scope of the initial analyses typically covers the entire plant area. When the project continues to a more detailed phase and process and instrumentation diagrams are done, the scope of the risk assessment is better for Hazard and Operability Study (HAZOP). If there are a great deal of tasks involving work steps or functions performed by operators or maintenance, for example Human Error Analysis (HEA) can be utilized.

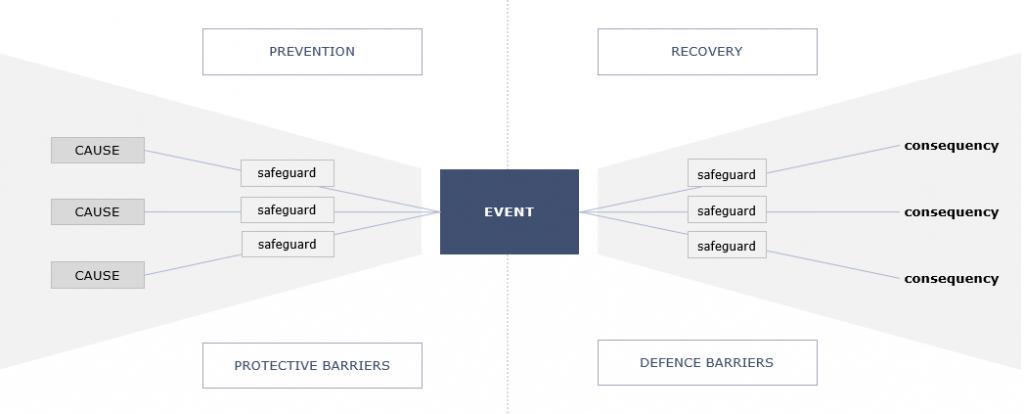

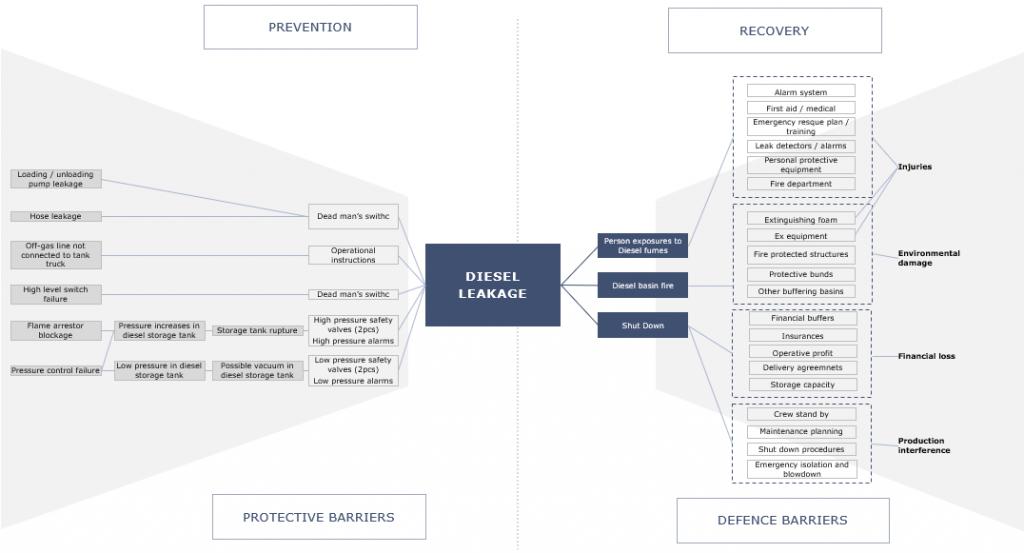

Describing the findings of a risk assessment using the Bowtie model

The Bowtie model presents the cause-and-effect relationships of the accident scenario as visualized in the bow model. This model is a good way to visually describe the results of a risk assessment to different parts of the company. The Bowtie model can also help to spread the expertise and share the causes and consequences of past accidents with different organizations with similar activities. The comprehensive Bowtie model is also an effective means of communication and a proactive tool for developing safety culture.

A good Bowtie model clearly shows the causes and consequences of the accident in one picture. The method clearly describes the causes, consequences and control measures of hazardous event (the main event, i.e. the risk) and the left side describes threat and special controls to eliminate the threat. The center of the model represents the main hazardous event (e.g., exposure, fire, environmental damage) and the left side describes the threats and special safety controls to eliminate the threat. The right half of the bow is reserved for the different types of consequences of the accident. Control and recovery barriers in the Bowtie appear on both sides of the main event.

The cause-and-effect bow of the accident scenario presented by the Bowtie model has proven to be one of the best methods to illustrate process industry hazards. The Bowtie method has been used by the Royal Dutch/Shell Group as the company's standard for risk analysis and management since the 1990s. Since then, Bowtie has been used by several different industries. It is suitable not only for different industries but also for scenario studies of different types of accidents.

The Bowtie model can be used, for example, to present the results of a HAZOP analysis for a main event with several different causes and consequences. If the results of the HAZOP analysis have also been considered for the worst-case accident scenarios by determining the safety integrity level (SIL), its findings can also be presented using the Bowtie model. It is important that the connection to the initial risk assessment presentation can be identified in the Bowtie model. When linking the results of different risk assessment and visualization methods, ready-made different risk assessment tools can also be utilized.

The Bowtie model works best as a complementary method to other methods of analysis. It can be comprehensively utilized in support of different risk analysis methods as an effective and illustrative visualization method to form an overall picture, especially for events that may have several different causes and involve different types of consequences.

AFRY’s global network of experts, together with local HSE experts, ensures an optimal solution for each safety-related assignment by ensuring compliance with legal requirements and other obligations.

Did you know? Each year our HSE experts facilitate several dozens of different types of risk analyses for different industries.