Towards safer hazardous areas (ATEX)

Many industrial facilities have a potentially explosive atmosphere, which requires following a number of obligations associated with ATEX regulations.

An area is considered a potentially explosive atmosphere if a potentially explosive air mixture is present. Ensuring the health and safety of workers in a potentially explosive atmosphere is the responsibility of the employer. ATEX directive regulations apply to the employers whose workers are at possible risk of being exposed to an explosion hazard due to flammable liquids, gases or dust. ATEX directives outline the safety precautions required for safe working conditions and the equipment used in the hazardous areas. But what are the responsibilities of the employer regarding the safety of explosive atmospheres?

Hazardous areas are classified into different zones according to the frequency and duration of the explosive air mixture. The classification of the zones determines the extent of the safety requirements for the equipment used or located in the area. The classification of the zones is based on explosion risk assessment, where the substances causing the explosion hazard are identified and the likelihood of the formation of the explosive cloud is estimated based on the present flammable liquids, gases or dusts.

The identification of the flammable gases and liquids is usually easy, but the identification of small amounts of chemicals or the small chance of explosive dust cloud formation may be challenging. Even small concentrations of chemicals may cause the accumulation of a fatal explosive air mixture. For example, in 2017, a surface treatment worker died to burn injuries caused by the explosion of a thinner barrel (volume 200 litres). Finnish Workers’ Compensation Center has created a video to describe the circumstances of the incident:

https://www.youtube.com/watch?v=qGtRfmZMkxE&feature=youtu.be

Compliance requirements for equipment - Whose responsibility?

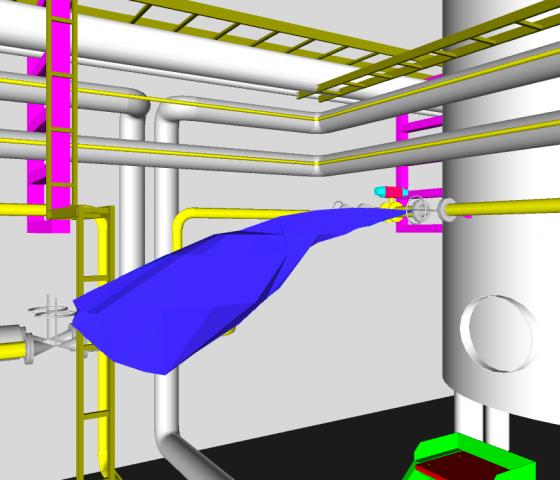

The presence of a potentially explosive atmosphere alone does not cause an explosion. The explosion can be avoided by, for example, choosing the equipment of the Ex-classified areas according to ATEX directives and by avoiding high surface temperatures. It is also important to identify all possible sources of ignition in the hazardous area. The figure below illustrates a leak from a flange connection containing an explosive gas cloud in a factory 3D-model.

Regarding equipment maintenance, it must be ensured that maintenance personnel is aware of the risks of explosion. Ex areas must be clearly marked and equipment must be regularly maintained and visually inspected. Regularly repeated and updated assessment of explosion and ignition risks is part of the continuous improvement and control of the safety and quality of the facility.

The conformity of equipment, that is, its suitability for classified areas, can be demonstrated by equipment classification or equipment markings and verified by a declaration of conformity (Directive on the harmonisation of the laws of the Member states relating to equipment and protective systems 2014/34/EU). In new plants, the conformity of the equipment is the responsibility of the equipment manufacturer, depending on what is required for the protection level of the equipment at the procurement of said equipment.

If new hazardous areas in an old facility are the result of process or machinery changes and if old equipment is still located in the newly classified area, the conformity of the equipment must be ensured by device-specific ignition risk analysis. The operator is responsible for preparing the risk analysis. When procuring new equipment, explosion risk assessment and the properties of the flammable substance define the protection level requirement for the equipment. The required protection level is provided to the supplier of the equipment. The equipment delivery must be performed according to the protection level definition or procurement documentation. The hazardous area classification can be executed by multiple different organisations in the project. The transfer of information between different parties is vital.

Explosion protection document - Part of the plant safety instructions

The results of explosion risk assessment and protection measures are gathered into the explosion protection document. The document has to be kept up to date, and the employer must ensure that the information is shared and that the measures are coordinated with the various parts of the organisation - especially if several different companies are working in the area.

Towards safer industrial facilities

Since the ATEX directive was published, the explosion risk assessment has slowly but surely developed safer industrial facilities. Lately, for example, with the measures presented below, progress has been made towards the safer handling of potentially explosive substances:

- Area classification is more specific (possible chemical leaks and identifying different types of dusts)

- Closed structures help limit the size of classified areas

- Chemical concentration is minimised with efficient air ventilation

- The amount of substances causing a potentially explosive atmosphere is limited according to the needs of the production

- Regular maintenance of the equipment (including preventive maintenance) and the tidiness of the process area are supervised

- Fire protection of the structures is ensured

- Incidents are reported proactively, and actions are taken

- Information concerning explosion risk assessment, classified areas as well as the technical and organisational prevention and protection measures is extensively documented into the explosion protection documents

The figure below presents the most important phases of the control measures for the potentially explosive atmospheres.

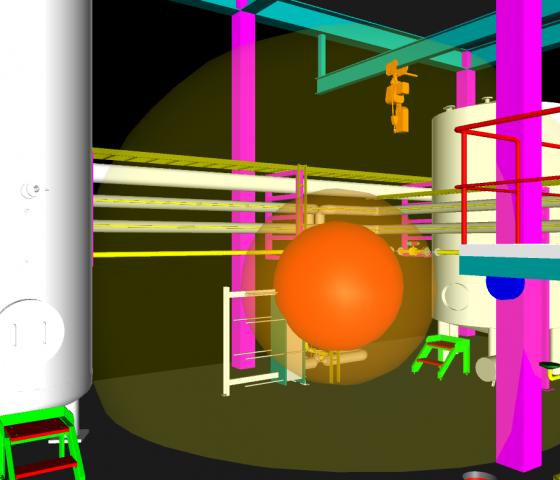

Expert help in the risk mitigation design of potentially explosive atmospheres

The risk management experts of AFRY Finland Oy can advise in the classification of potentially explosive atmospheres, ignition risk assessment and simulate the possible hazards to support in the preparation for an accident scenario. For example, in the figure below, the overpressure wave effects of the explosion of the potentially explosive atmosphere are presented in 5 kPa, 15 kPa and 30 kPa, as required by the authorities. The flammable cloud reaches the ignition source located two metres from the flammable chemical leakage point.

AFRY’s experts train employees as well as client organisations in tasks related to hazardous area classification. We actively monitor the development of legislation and standardisation and participate in standardisation working groups.

Obligations related to potentially explosive atmospheres:

The obligation to assess the explosion and ignition risks and to prepare an explosion protection document is based on the Government Degree on protecting workers from danger caused by potentially explosive atmospheres (VNA 576/2003) and the Act on the Handling of Dangerous Chemicals and Explosives (390/2005). This regulation is based on EU Directive 1999/92/EC providing minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres. Instructions for hazardous area classification are given e.g. in the SFS Handbook 59 and in the standards IEC 60079-10-1/-2.