Unlocking the by-product potential of a modern softwood pulp mill

Written by Jarno Peltonen, Emma Kärkkäinen, Petri Qvintus and Jens Kohlmann

Today’s pulp mills can be called “bioproducts mills” or “biorefineries” due to their various side products.

AFRY studied commercially available technologies in side stream utilisation and analysed technologies with pulp mill concepts.

Side stream utilisation can increase both the economic and environmental benefits of pulp production and be implemented in both existing and new mill sites. With the continuously growing demand for fibres and other bioproducts, steps towards circular economy are required to further improve the environmental sustainability of pulp production. Industrial circular economy solutions are unlocking the potential of efficient side- and waste stream utilisation and modern pulp mills are a great example of how sustainable bioproducts can be derived from renewable biomass.

With advancing technologies, many new value-added end uses are emerging from the pulping process or its side streams. These products will have all the properties needed to replace the fossil-based materials with minimal carbon footprint. This “pulp revolution” will help us to reduce our CO2 emissions and reach the fossil-free targets. We will see an exponential growth of new bioproducts in areas such as construction, transportation, energy, a multitude of consumer products and in food and pharma.

The assessment of the by-product potential

To support this emerging side stream utilisation, AFRY has assessed the by-product potential based on a review of commercially available technologies. Several alternative cases for the setup of the same mill were reviewed as part of the assessment.

Side streams included in the assessment were crude tall oil, sulphuric acid, methanol, lignin, electricity, bark-based pellets and biogas (for lime kiln fuel). Both black pellets and conventional pellets were studied as options.

In addition to these mapped side streams, there is potential for other by-products but many of the technologies are not yet commercial or have country-specific legal aspects that need to be considered. These technologies are developing quickly and were thus excluded from this assessment.

Introducing the analysed cases

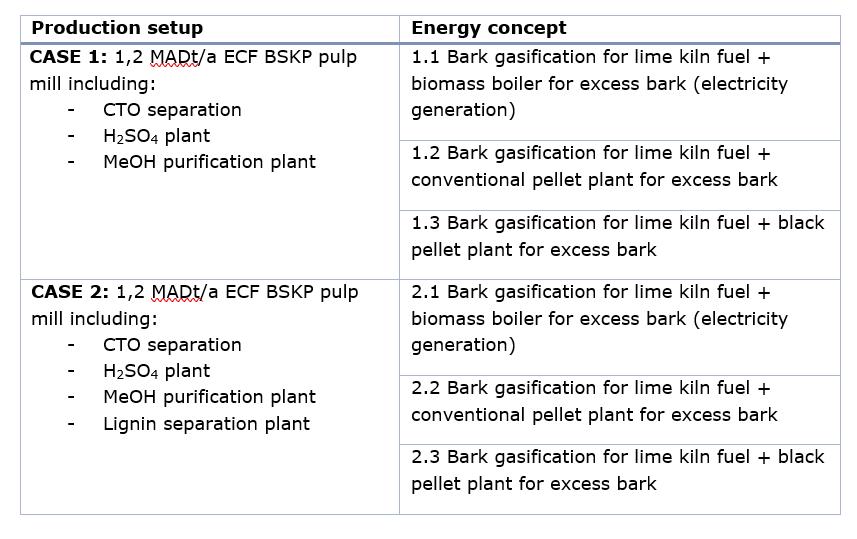

A state-of-the-art bleached softwood kraft pulp mill with an annual capacity of 1.2 million air dry tons was assessed in terms of side stream availability and capacity. Crude tall oil, sulphuric acid and methanol production were included in both Cases 1 and 2, whereas Case 2 also featured a lignin separation plant. Additionally, both cases were studied with three alternative energy concepts as described in Table 1. The calculations were conducted with pulp mill fibre, chemical and energy balances.

Findings of the assessment

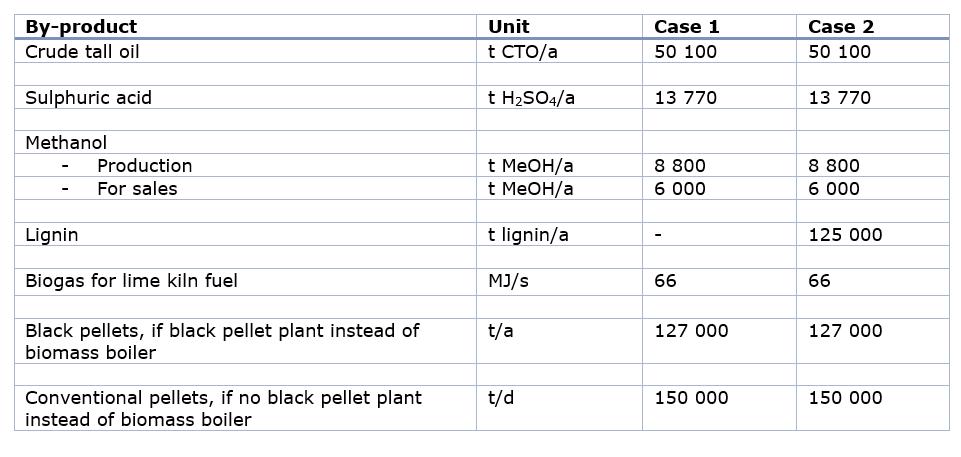

Crude tall oil, sulphuric acid and methanol production capacities were similar in all cases (142 t/d, 40 t/d and 28 t/d, respectively). CTO and methanol capacities mainly depend on the wood raw material used, and thus were similar in all cases. Sulphuric acid is manufactured from concentrated non-condensable gases and is dependent on e.g., the white liquor sulphur concentration and possible black liquor heat treatment in the evaporation plant.

The results are summarised in the table below:

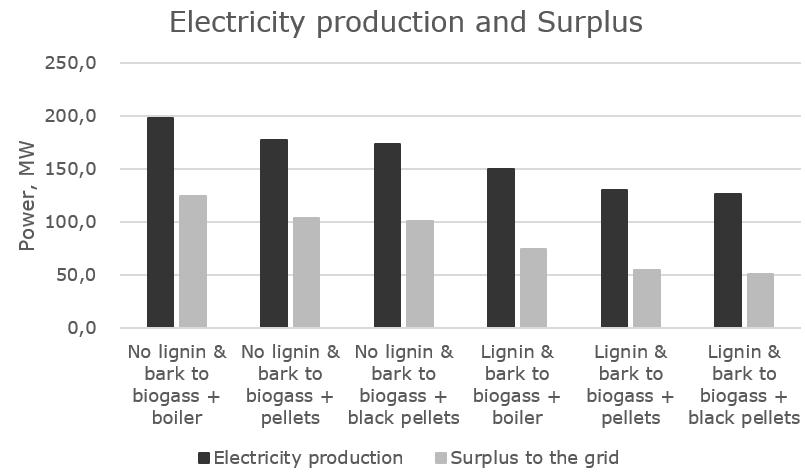

Electricity generation and surplus for sales are summarised in the graph below:

Electricity generation potential was highest in Case 1.1 and decreased in subsequent cases. In Cases 2.1, 2.2 and 2.3, electricity generation is lower due to lignin removal as the removed lignin does not contribute to energy. The declining trend from Case 1.1 to 1.3, as well as from 2.1 to 2.3, is due to material being removed for pellet production. The energy stored pellets can then be utilised in another facilities. Lignin can be further refined into a variety of products, such as resins or dispersants.

Summary

It is obvious that side product potential depends on the overall mill concept that defines the pulp production. Not all side products are feasible or possible for all mills due to differences in the mill setup as well as the raw materials and chemicals used. Therefore, the side product potential has to be studied on a case-by-case basis for different mills.

In our example pulp mill cases, CTO and methanol capacities were similar since they depend on the raw wood used. The production of sulphuric acid was the same for all cases studied as well, but there could be more differences which have been studied by AFRY separately.

From the electricity production point of view, it is obvious that lignin removal from the process or utilising bark for pellet production will reduce electricity generation but provide other sellable products. The energy stored pellets can be utilised in other facilities and lignin can be further refined into a variety of products, such as resins or dispersants.

AFRY offers strong business, technology, and process know-how for pulp industry clients

AFRY is ranked #1 in the world in the pulp and paper industry (ENR Global Sourcebook 2021). We offer our clients thorough reviews of side stream utilisation for new and existing mills in order to recommend steps towards even more sustainable, profitable and efficient pulp mill operations.

Understanding the pulp industry value chains and the pulping and biorefining processes is a strong part of our heritage. AFRY is a world leader in forest industry consulting and engineering and has been the partner of choice for the majority of global pulp producers for decades.