Delivery of robot cell that performs 3D scanning, to Plåtson AB, Sweden

A combination of 3D scanner, robot and reporting module with cloud storage makes AFRY one of the first companies in Sweden to deliver a unique solution that helped the client, Plåtson, to take a big leap forward in their technical development.

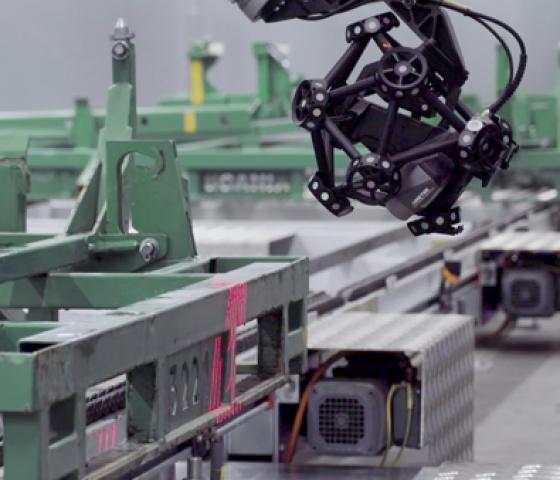

Plåtson (AB), is a mechanical engineering company in Oskarshamn, Sweden, that is responsible for the controls of Scania’s 7,000 stands used to transport truck cabs between its factories in Sweden, the Netherlands and France.

Plåtson contacted us wanting to make their work more efficient and quality assured. Our solution met their needs, which meant they were able to secure the contract with their client

- Magnus Axelsson, Section Manager at AFRY.

Previously, the stands were controlled manually by taking a measurement that took 3–8 minutes per stand, depending on the operator and outcome.

The development of the new work process was done together with the client and AFRY’s goal has been to deliver a sustainable, efficient and ergonomic solution with a focus on digital development. Our solution enabled Plåtson to measure a stand in 2 minutes and 40 seconds with 100 per cent quality assurance.

AFRY was responsible for the development of technical concepts, design, electrical engineering, PLC and robot programming, as well as the development of reporting systems with cloud storage and electrical installation.

The solution delivered by AFRY consists of three parts:

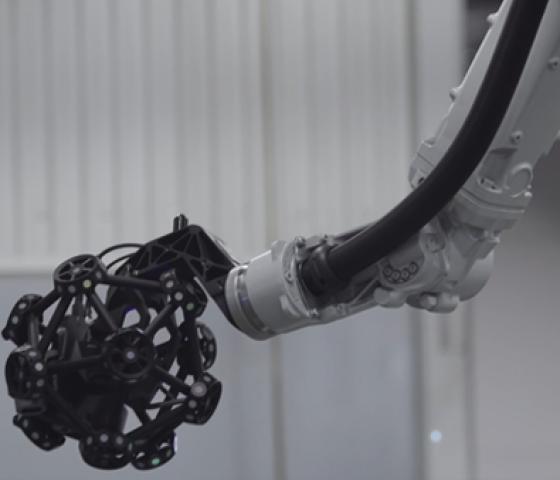

Robot:

Allows scanning of the stand from all the necessary angles and focuses on the details necessary for a good result. The robot also carries the camera securely and never fails. It can also be mounted upside down, making the equipment more flexible with the robot no longer taking up space on the floor and giving it space to work freely around the whole stand.

MetraSCAN camera:

An advanced 3D camera from the French company Creaform (through Creaform's dealer MLT), which features high measurement precision on all types of materials including black, multicoloured and shiny, a volumetric accuracy up to 0.064 millimeter and high repeatability regardless of environmental instability.

The 3D camera produces fast scans, has a wide scan area and high measurement speed of 480,000 dots/second. The camera and robot are also programmed for auto calibration, which ensures the measurement quality. To read more on MLT's website, click here.

Reporting programme:

To complete the work process, AFRY developed the reporting module, which presents and stores the results digitally, enabling the client to monitor the results in real time, as well as facilitating analysis work for development of the stands and/or the end client’s production facility. The reporting module comprises a local WPF (Windows Presentation Foundation) application with an Azure website for cloud storage.

Interested in our offering? Contact us!