900 MW Nant de Drance Pumped Storage Power Plant, Switzerland

Increasing power production from the Emosson reservoirs in the Swiss Alps

The Nant de Drance pumped storage facility was designed to exploit part of the enormous hydroelectric potential of the Swiss Alps for stabilizing the European grid and securing Switzerland's power supply. It is one of the most powerful pumped storage plants in Europe and has a storage capacity of 25 million m³.

AFRY was commissioned by the client in 2002 to develop this project and to bring it to implementation maturity via the feasibility study, the preliminary, construction and conditional project as well as via the tenders.

Construction work began in autumn 2008, with AFRY as overall planner until autumn 2012. From autumn 2012, AFRY took on various key roles in the project. Among other things, AFRY was in charge of the technical coordination of the overall project, execution planning, project controlling, setting up a data management system, construction planning and management, hydraulic steel structures, electro-mechanics and electrical engineering, as well as increased monitoring of dams and valley deformations.

The plant was commissioned in autumn 2022.

AFRY's role in Nant de Drance as hydropower consultants

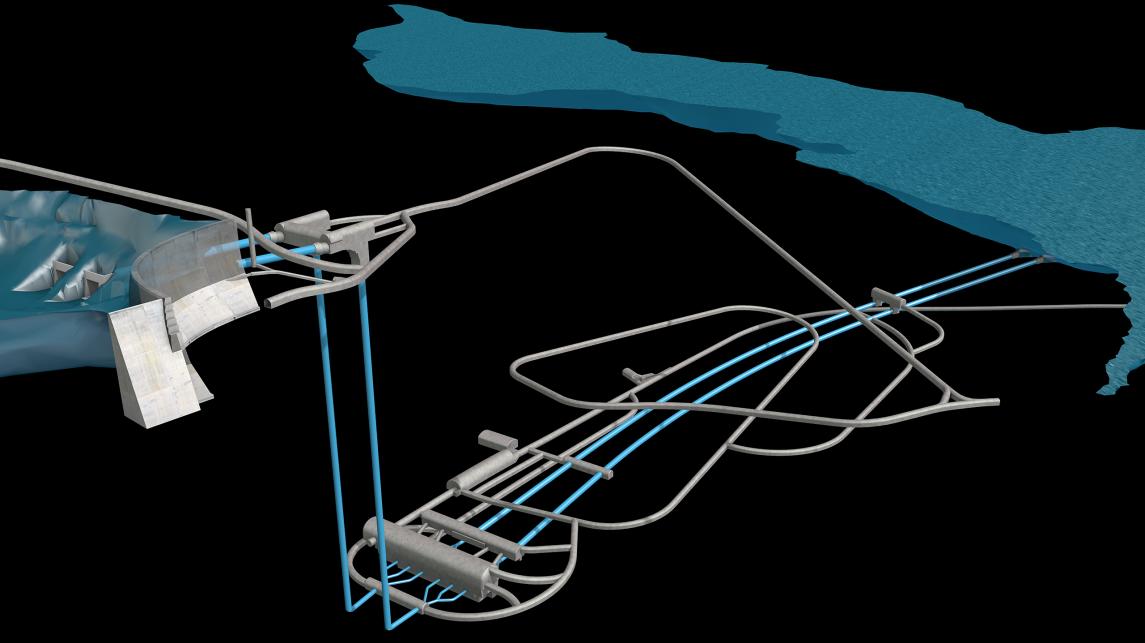

The 900 MW Nant de Drance pumped storage power plant was developed incorporating the two existing reservoirs Vieux Emosson (upper reservoir) and Emosson (lower reservoir) in the Valaisian Alps along the Swiss and French border. The available head between these two reservoirs is up to 395 m. The capacity of the upper reservoir was doubled by increasing the height of the existing dam wall by 20 m.

The headrace system is designed in two independent parts. Each part consists of approx. 2350 m of pressure tunnels and a 425 m deep vertical shaft. 13 km of tunnels provide year-round access to the facilities.

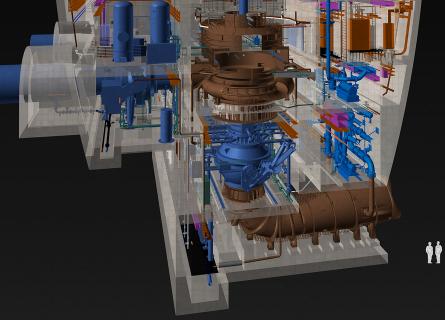

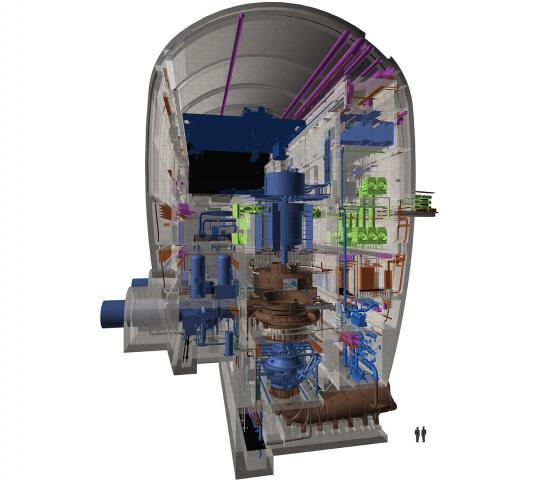

The underground power plant complex consists of the power plant cavern (194x52x32 m), the transformer cavern (132x18x18 m) and three access tunnels. The longest tunnel is the main access tunnel to the machine cavern. It is 5.6 km long, driven by a hard rock TBM with a diameter of 9.45 m and a maximum gradient of 12% (winter access).

The six vertical reversible Francis pump-turbine units of maximum 157 MW each and the vertical asynchronous motor-generator units of 170 MVA as well as other central plant elements constitute the core equipment of the Nant de Drance pumped storage power plant.

AFRY provided a wide range of services in many disciplines throughout the course of the project from the preliminary study to commissioning.

Overall management

- Overall planner (all specialised fields) for the phases of preliminary study, preliminary project, construction project, construction and concession application, tendering and realisation (until 10/2012)

Technical coordination

- The technical coordination was executed using BIM (Building Information Modeling) and the BIM-Method: 3D-models of the civil structures and various equipment such as valves, turbines, generators, cable ducts, pipe systems, etc. were exchanged between AFRY and the suppliers to coordinate and optimize the layout and arrangement of the power plant; Issue Management of change requests, detected clashes or other problems; the models were used for visualisation and simulation of assembly processes.

- AFRY obtained the Arc-Award BIM with focus on Collaboration in 2017 (Organizer: Docu Media Switzerland, awarded by: Swiss Construction Documentation) for the work performed in Nant de Drance.

Project management

- Project controlling with overall cost management, final cost forecasts, contract management, claim management, risk management, construction and sequence planning, information management over the entire construction period, client support incl. preparation of project handbook, and transfer of project costs to the client’s operating accounts

Data management

- Setting up data management systems with a coordinated data model, including setting up and monitoring an interface for the mutual exchange of documents

Tunnelling

- Optimisation of preliminary project, construction project, preparation of tender documents and evaluation of bids

- Implementation planning for headrace tunnels, access tunnels/tunnels, shafts and various caverns

- Technical site management; supervision of commissioning; member of expert group on dam safety

Hydraulic steel structures

- Headrace tunnels consisting of inlet/outlet structures, concrete and steel-armoured headrace tunnels, gate chamber with butterfly valve, vertical shafts, gully cavern with two roller gates;

- Studies, preliminary design, tender design and construction planning, tendering procedure, bid evaluation, implementation planning and technical construction management

Construction management

- Chief construction management (until 07/2011)

- Chief construction management, local construction management according to SIA phase realisation incl. schedule, contract and cost management

Electromechanics

- Pump turbines, upstream and downstream ball valves, motor-generator with frequency converter, controllers (hydraulic and digital), cooling system, pressure shaft filling system, compressed air system, oil storage and treatment systems, crane systems in the caverns

- Preliminary studies, model test, project planning, construction project, preparation of tender documents, comparison of offers and award of contracts, project management and implementation planning as well as support during installation management and commissioning

Electrical engineering

- Transformers, GIS system, own consumption, process control technology and protection (aid)

- Preliminary studies, project planning, construction project, preparation of tender documents, comparison of bids and award of contracts, project management and implementation planning as well as support during installation management and commissioning

Building services

- Sanitary, HVAC, light + power, fire protection

- Pre-project, building project, building and concession application

- Support for construction management of interior work

Safety

- Setting up monitoring concept

- Increased monitoring of the dams and valley deformations during excavation in blasting and TBM tunneling (DAMOSY software)

- Monitoring of the displacement of caverns and galleries (2doc software)

- Drawing up a safety concept for the entire plant

- Planning and following of the first filling

- Member of the SFOE expert group

Hydrogeology

- Creation of a hydrogeological model in the feasibility study

- Planning and realisation of various geotechnical solutions.

Client: Nant de Drance SA, founded on November 7, 2008 with the holding companies, Alpiq Suisse SA (39%), Swiss Federal Railways (36%), Industrielle Werke Basel (15%), Canton Valais (10%).

Total project costs: approx. CHF 2.2 billion

Total AFRY remuneration: approx. CHF 100 million

Development period: 2002—2022

Services:

- preliminary study (2002)

- preliminary project (2004—2006)

- construction and concession application (2006—2007)

- call for tenders (2006—2007), realisation (from 2008)

- construction and installation management (from 2008)

- commissioning (aid) (2017—2022).

Martin Aemmer, then Head of Business Unit Hydro, Switzerland:

Nant de Drance is one of the beacon projects of Swiss hydropower in modern times. The visionaries demonstrated foresight with this project many years ago. AFRY is proud to have contributed significantly to the overall development of this project with its vast competencies in the fields of energy and infrastructure.

Nant de Drance as a project of the century

With costs of just over 2 billion Swiss francs, the project will be an important component of the Swiss and European energy strategy. Thanks to the installed capacity of 900 MW, the power plant will be able to produce large amounts of electricity or store energy within a very short time. The high flexibility will be one of the main strengths of this plant, as the volatile amount of electricity generated from the new, renewable energy sources can be optimally stored in this way.

Interested in our offering? Contact us!