Power to the soil

Better harvests with the help of used batteries? It may sound like science fiction, but Finnish start-up company Tracegrow has made it possible. Their new recycling process introduces a better way to restore the metals in our disposed batteries – and at the same time create a completely recycled fertiliser that solves the shortage of important nutrients in the soil. AFRY has cooperated with Tracegrow to revamp their current production plant and find new ways to purify and reuse harmful waste.

”Before joining this project I would have never thought that you could make fertilisers out of the batteries that are powering my flashlight,” says Tuukka Sormunen, project director at AFRY.

Reusing products made for one purpose to something completely different is one of the great opportunities of the growing circular economy. Limited resources are forcing us to be innovative and redesign our processes into ones where the room for waste is limited. One such example is the Finnish cleantech company Tracegrow, who realised the problem with hazardous battery waste and knew that something had to be done.

A circular solution to harmful waste

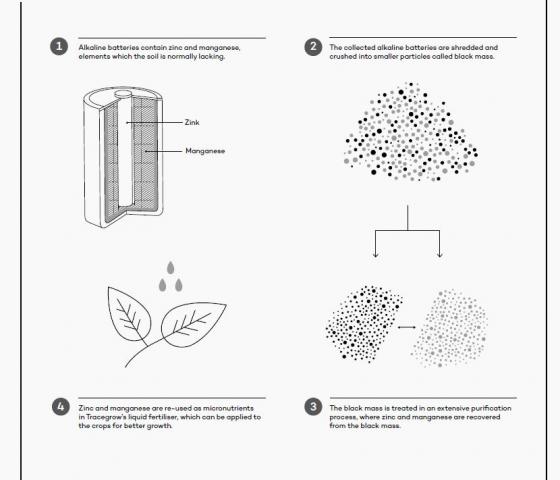

Over ten billion alkaline batteries are produced worldwide each year. Even though they are important for powering smaller devices such as flashlights and remote controls, the disposable batteries can only be used once, up to about 100 hours, before they are discarded. The same goes for the valuable metals inside. Due to the lack of efficient recycling, some countries, such as the U.S., favour the disposal of single-use batteries in the household trash before recycling options. Within the EU, about 44 percent of sold batteries are returned to recycling bins. But even though used-up batteries are collected, a large portion of the trace metals is never recycled. When the batteries are crushed, steel shells are magnetically separated, but the mix of trace metals inside the battery – the so-called “black mass” – is put into a smelting process. This process requires large amounts of energy and only zinc is recovered, whereas manganese is wasted to the slag.

“We knew the inefficiency of the current recycling process, and had an ambition to develop a new product out of the black mass, but we didn’t know what that would be. Our new owners entered in 2015, and with their background in farming they saw that zinc and manganese, which are found in the black mass, are elements which the soil is normally lacking. So we connected the dots and decided to make a fertiliser,” says Mikko Joensuu, CEO of Tracegrow.

Zinc and manganese are important elements that both make crops grow better and are necessary for fundamental biological functions in both animals and humans. Today, zinc and Power to the soil ”Even though many used-up batteries are collected, a large portion of the trace metals are never recycled.” manganese are added to the crops through traditional fertilisers. With Tracegrow, these fertilisers can be replaced with an equivalent that is reusing zinc and manganese from batteries – with the same blooming crops as a result.

Tracegrow’s first production plant opened in Kärsämäki in 2018, and today the plant delivers liquid fertilisers to eight countries around Europe. AFRY has been partnering with Tracegrow to develop and ex- pand the Kärsämäki plant, as well as conducting a pre-engineering study for the new plant underway.

Purification the greatest challenge

As with most secondary raw material, the restoration and purification of waste into useful material is challenging. Since the metals from the black mass are circulated back directly onto the crops, the process for purification into Tracegrow’s fertiliser is critical. The fertiliser legislation is very strict, both in the Nordics and the rest of Europe, ensuring that the traces of harmful metals are sufficiently low in concentration. It has therefore been crucial to continuously develop the process and find new methods for creating a cleaner end-product, something AFRY has been a part of.

“The technical challenge is to make sure that the black mass is clean and does not contain any harmful metals, such as nickel or cadmium. This requires more extensive separation processes where we can be more precise and extract only zinc and manganese from the battery crush. But in the end, the reward is a fertiliser so clean that it may be used in organic farming,” says Tuukka Sormunen.

The problem with hazardous waste does not stop with alkaline batteries. There are many other waste materials that could be reused into new products. Tracegrow, supported by AFRY, is looking at new potential concepts to enhanche circular solutions using secondary raw materials. “The current plant could easily produce other liquid fertilisers as well, which could be relevant if the right trace elements are found in other wasted materials. In the future we will probably have five to ten different fertilisers in our product family,” says Mikko Joensuu.

Interested in our offering? Contact us!