AFRY RAMS - reliability, availability, maintainability and safety

Product Information

Enabling you to take your asset management to the next level

Do you know where your risks really lie? What are the most feasible and reasonable improvements you should focus on? Do you collect the right data to improve your operation and maintenance (O&M)?

AFRY’s life cycle services provide clear analysis to make the right decisions to reduce risks, increase production and safety and enable you to focus your resources where they matter most.

Customer Needs

Many companies have increasingly put operational excellence and asset management as one of their key development priorities. It has become obvious that staying ahead of competition needs better understating on ‘how does our current performance look and what are the best options to improve it?’ The current challenge is often a lack of reliable analysis of the current status of O&M and comprehensive and reasonable analysis. Knowing where to put efforts in order to achieve best results not only in the short term but over the planned life cycle also raises questions.

Ultimately, asset management is managing risks.

The risk management approach emphasises proactive actions and life cycle perspective. The challenges are how to reliably identify and classify risks and how you should allocate your resources to efficiently remove and mitigate them.

Instead of local optimisation, the better outcome would be achieved by dissecting the whole O&M functions and processes, making the analysis and action plan as a result.

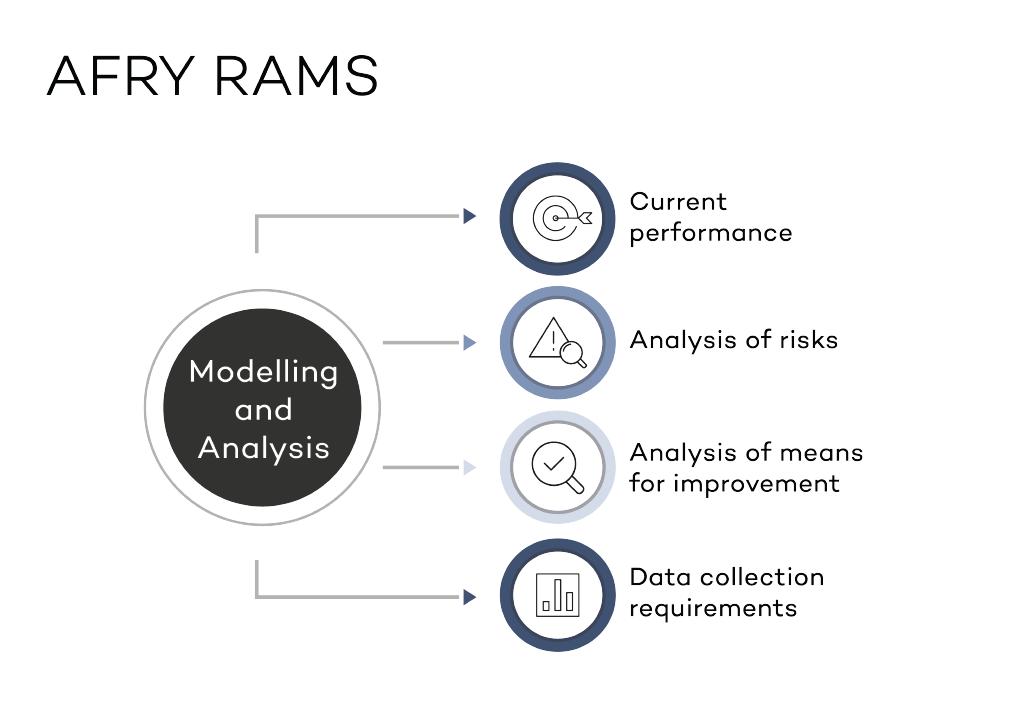

RAMS analysis applies very efficient and flexible tools to identify risks (business, environment, safety) and classify them based on their failure consequences. It gives a holistic view over the performance and improvement options of the assets. Additionally, this analysis brings foundations to data and information collected from O&M, as through analysis we have a better understanding of what is critical, and why and how to make better analysis in the future.

AFRY has been conducting RAMS analysis for many years. The methodology is supported by the state-of-the-art Event Logic Modelling and Analysis Software (ELMAS), reliability experts, and AFRY’s deep technological and business knowhow across different industries.

Our RAMS analysis helps and enables your organisation to achieve the following main targets:

- Understanding the critical assets and critical risks – based on cause-consequence modelling

- Analysis on current performance and performance gap

- Most feasible improvement options

- Optimised maintenance program and spares

- Data collection analysis – focus on relevant and accurate O&M data in order to have better analysis in the future

The above targets enable you to make better informed decisions based on understanding such as where are we, what should be done, and how. Additionally, the methodology brings excellent tools for continuous improvement.

AFRY’s RAMS methodology narrows down the focus of the analysis to the critical assets, where the value-for-money is. The methodology is applicable for any industry. It supports ISO 55 000 fundamentals perfectly. It covers operating plants but it is also an efficient tool when planning and designing new facilities; green field, brown field, upgrades, etc.

AFRY’s RAMS methodology is flexible and scalable. It can be started from selected systems, and later on extended to cover the whole plant or site.

AFRY’s methodology is efficient from two points of view, focusing on the essentials, and requiring only a reasonable amount of the client’s time.

We help you to lower your operational risks, lower operational costs, and increase revenues.

AFRY’s RAMS methodology has been utilised in different industries. It has collected otherwise hidden information from the organisation and revealed potential risks.

AFRY’s RAM’s methodology typically improves design solutions’ overall availability 1-3% -units.

AFRY’s clients have been able to improve their production e.g. by investing 200 k€ achieved 1 M€ saving.

Interested in our offering? Contact us!