Asphalt Sealing Elements

AFRY provides services for the application of asphalt in various fields of construction

In the history of mankind, asphalt has always been used. The first applications are traced back to approximately 5,000 years ago, when asphalt was employed as mortar between stones for a small dam built in the Indus River. Nowadays, asphalt can be seen as one of the most commonly used materials in construction around the world because of the tremendous adaptability and characteristics of the material itself.

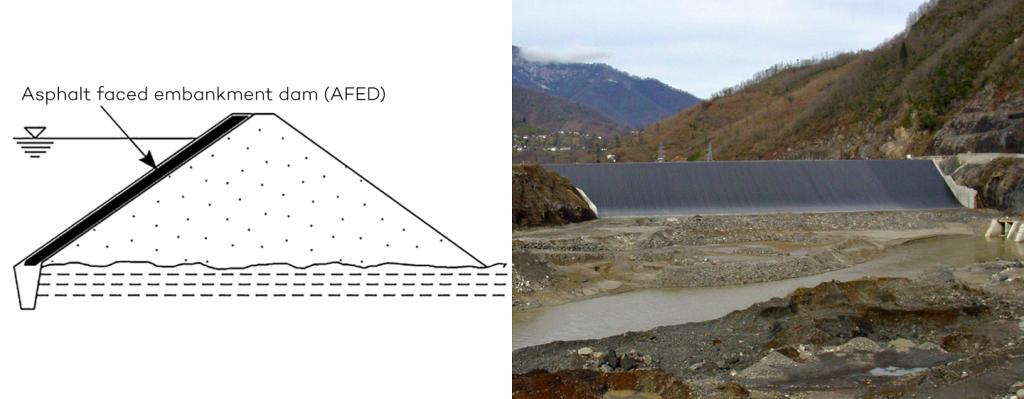

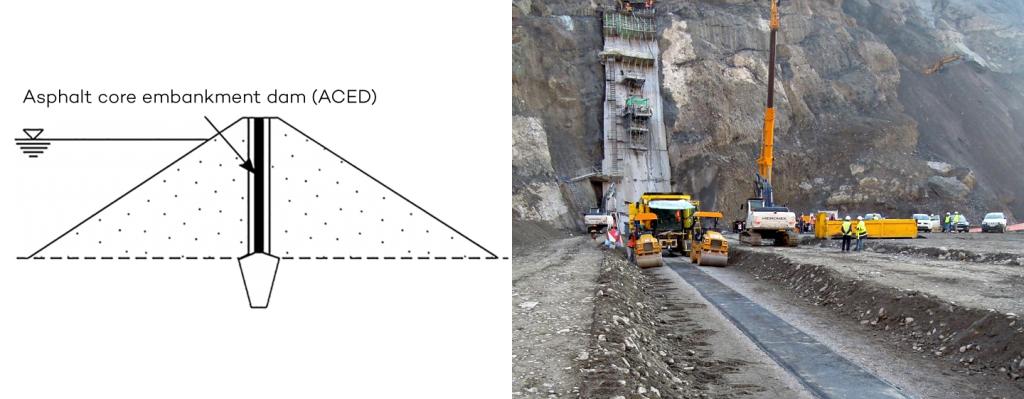

Asphalt sealing elements are used to make embankments (dams or channels) watertight, stable against erosion and to protect the subgrade/soil from contamination. They are divided into two system types:

Surface sealing for dams, reservoirs, channels, landfills and waste disposals

Core sealing system for embankment dams

Advantages of asphalt surface sealing elements

- Performance records from existing asphalt facings show no leakage through the asphalt concrete, provided it was well designed and constructed.

- High durability even in harsh climate regions, service time of more than 50 years.

- Fast construction without joints.

- Asphalt sealing system and material characteristics can be tailor made according to site conditions.

- High flexibility of the asphalt facing (facing can undergo large deformations before cracking).

- High resistance against external damage (ice floes, rockfall etc.).

- Repair works can be easily performed.

- The raising of Asphalt Faced Embankment Dams (AFED), is easy to execute.

- In order to meet various requirements derived from project boundaries such as subgrade or dumped material, every lining system characteristic and the asphalt to be used can be tailored accordingly.

- With modern asphalt material design methods and construction techniques, impermeable sealings can be constructed even on challenging subgrades and geometries.

- The larger the area of the sealing system is, the greater the economic benefits are.

Advantages of asphalt core sealing elements for embankment dams

- Performance records from existing Asphalt Core Embankment Dams (ACED) show no leakage through the asphalt concrete core if the dam was well designed and constructed.

- ACEDs are fast and easy to construct and the construction is much less impacted by weather conditions. For example, in areas with high precipitation, the overall construction time for an asphalt concrete core is lesser than most of the other dam types.

- Construction costs in comparison to other dam types can be decreased in most cases due to the fast construction of an ACED. The limiting factor for the construction schedule is the progress of the embankment fill.

- The larger the core length, the more are the economic benefits of the sealing system.

- Inside the embankment, the asphalt concrete core is embedded under ideal conditions and independent from external climatic impacts. It will remain flexible and impervious over the dam’s lifetime.

- Asphalt concrete cores in the interior of dams provide the highest protection against damage caused by acts of war or sabotage.

- The core sealing system can be tailor-suited to optimize the load-deformation behavior of various load cases.

- Asphalt core sealing systems are suitable for seismic regions.

Reference projects

Our team of specialized engineers has successfully executed numerous projects around the globe.

These are some of our key projects:

AFRY material and design expertise for asphalt sealing elements

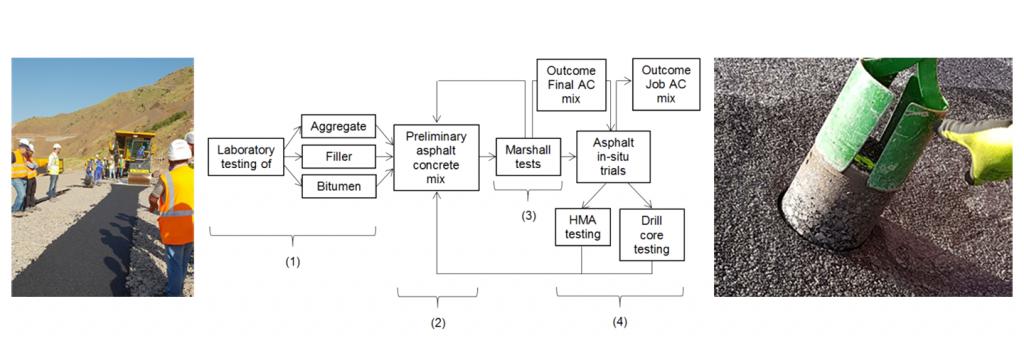

Our services start at the project idea and continue until the sealing element system is completed.

- Alternative and comparison studies in order to define the optimal sealing system for our clients

- Design and optimization of asphalt sealing systems (AFED, ACED, etc.)

- Development of high-performance asphalt mixtures

- Material specifications (definition of mineral aggregate and bitumen characteristics and source requirements)

- Laboratory tests (standard and performance-based test procedures)

- In-situ asphalt trial tests

- Support during the tender phase (B.o.Q., tender documents, selection of supplier etc.)

- QA/QC and site supervision

- Design of repair works for asphalt sealing systems (inspection, maintenance plan, etc.)

- Specifications for site laboratory equipment and support for machinery equipment

Asphalt material expertise

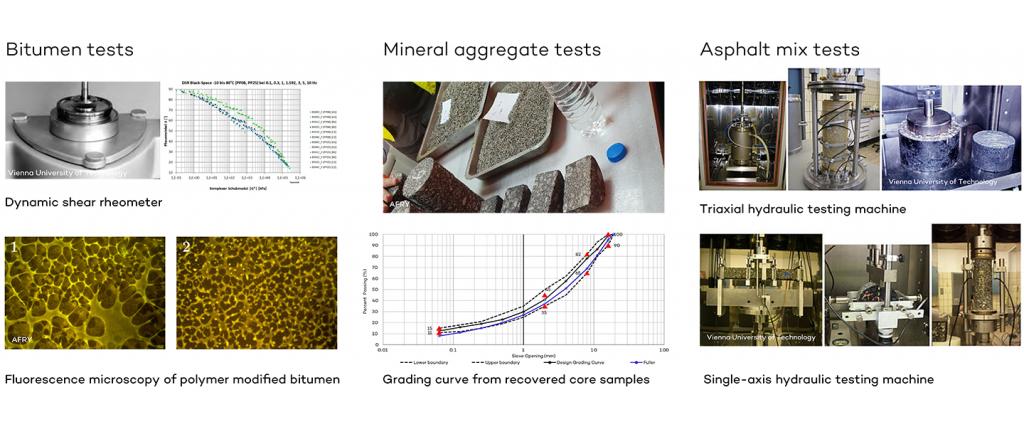

Asphalt is basically a composition of aggregates, bitumen and air voids. Not every asphalt mix is suitable for all applications. The requirements for road asphalt are fundamentally different as compared to asphalt in hydraulic engineering or asphalt for landfills and waste disposals. The mix design for asphalt concrete for road constructions is focused on durability, stability and surface quality. Whereas, the main characteristic for asphalt used in hydraulic engineering and for landfills is impermeability and flexibility. The selection and development of the correct asphalt mix and the application technique makes the use of the asphalt as a sealing material sustainable and cost-efficient.

The latest state of the art laboratory methods and equipment are used to provide our clients with advanced asphalt mix designs. Bitumen qualities vary widely depending on the crude oil source. Performance-based bitumen testing and comprehensive experience allow our experts to design sufficient asphalt mixtures, even with lower bitumen qualities.

Our inhouse expertise and the access to the latest state of the art material testing equipment, enables us to provide high performance asphalt mixtures exclusively for your construction project.

We work in partnership with the Vienna University of Technology for research and development of the application of asphalt in hydraulic engineering.

Interested in our offering? Contact us!