Basic & detail design and procurement support for nuclear power plants

Basic and detail design engineering services in the nuclear project development phase

AFRY provides basic and detail design engineering services and procurement support in nuclear power industry for new build and plant upgrade projects

When a client is planning a new or upgrade project, the basic design is developed in the project initial stage to define the design basis, pre-size systems, define functional and the space requirements and cost estimates. Basic design provides the necessary input data for the detail design.

Detail design is developed when the client wants to define the detail technical specification before project implementation or the client intends to launch a tendering process for the project, to be based on a detail design.

Typical features of basic and detail design for nuclear facilities

- The design is developed for all plant parts – nuclear and conventional island

- The design is coordinated among and includes all the technical disciplines – architectural, civil, process & mechanical, electrical, I&C, etc.

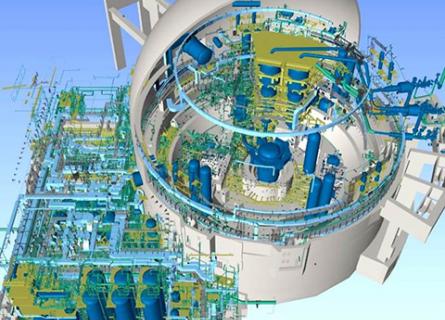

- The design is developed by application of 3D software

- The design reflects Best Available Techniques (BAT) and regulatory requirements – safety, environment, operation, etc.

- Both the basic and detail design can be used for the tendering process of the project implementation phase.

Procurement engineering and benchmarking for nuclear equipment

AFRY's nuclear consultants provide procurement advisory services to guide the clients through the procurement process for nuclear equipment and services in new build and plant upgrade projects to ensure that the procured goods and services:

- Comply with legal regulations and standards

- Fit to the purpose required by the client

- Have the desired features and quality

- Are delivered on time and within a reasonable budget.

What services do AFRY provide in the procurement process?

- Definition of technical specification and requirements on the specified components and equipment

- Preparation of the list of possible vendors

- Technical comparison of vendors' quotations

- Review and approval of the manufacturing documentation made by vendors

- Preparation of detailed time schedule of the components & equipment manufacturing

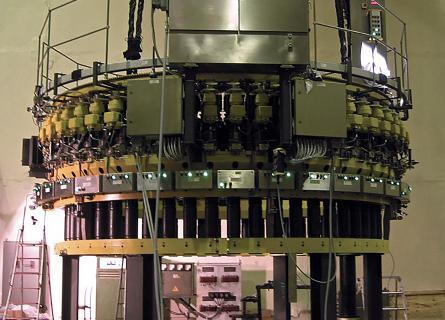

- Overseeing the manufacturing process at vendors facilities

- QA/QC verification of vendors (inspections, testing and examinations during manufacturing)

Interested in our offering? Contact us!