Computer Aided Engineering

CAE

Reduce risks, predict behavior, and improve performance, long before you can actually test it!

Computer Aided Engineering (CAE) is an excellent engineering tool to obtain deep knowledge for products and processes in a short time and with no physical risks. We help our clients to develop sustainable solutions in several different market areas such as the automotive industry, process industry, food and Pharma, oil and gas, nuclear power, aviation and aerospace, forest industry and infrastructure.

In the early stage of product development and process optimization we use CAE to:

- Predict product and process behavior

- Improve product and process performance

- Reduce risks and lead times in projects

Our main areas of CAE expertise are: Finite Element Analysis (FEA), Finite Element Method (FEM), Computational Fluid Dynamics (CFD).

Computational Fluid Dynamics (CFD)

CFD is one of the powerful tools we use to support our client in decision making in complete product development projects, large infrastructure projects as well as designing process equipment. The digital simulation can predict and visualize different scenarios using the combined knowledge of our AFRY experts within a large number of industries.

In product development CFD is an important tool to analyse, optimise and verify the performance of designs before costly prototypes and physical tests.

CFD is a numerical tool that can be used for solving flow, energy and mass transfer in complex system. We work with systems of equations for continuity, impulse and energy conservation of a fluid.

We supply projects and engineering resources from our offices, or alternative on-site at your location.

Some examples of what we can support you with:

- Flow analysis

- Mixing

- Heating and cooling applications

- Combustion

- Multiphase flow

Software

We have experts in several common software such as:

- ANSYS

- StarCCM+

- Comsol

- GT-Suite

- Modelica

- ... and many more

Please ask us about the software of your interest!

Automotive

The automotive industry has a long tradition in using Computational Fluid Dynamics in their product development. The usage is not limited to external aerodynamics that is shown in the image.

Examples of applications where CFD successfully is used are, but not limited to, batteries, cabin comfort, exhaust after treatment, Thermal management and etcetera.

Urban planning

When new urban areas are to be planned that affects the amount of traffic in the area it is necessary to verify that the particle and nitric oxides pollutions are within legislation limits.

AFRY are using Computational Fluid Dynamics in three dimensions to account for variations in ground level, trees/forests and the complexity of the buildings.

Since the solution is in three dimensions, we are able to validate the effect of different solutions if legislation levels are not met.

Process Industry

With the help of Computational Fluid Dynamics, we have helped customers in upscaling pilot plant reactors to production plant size.

In a particular case the process is used for the production of a sustainable replacement of natural gas using carbon from sustainable sources thus reducing the carbon footprint.

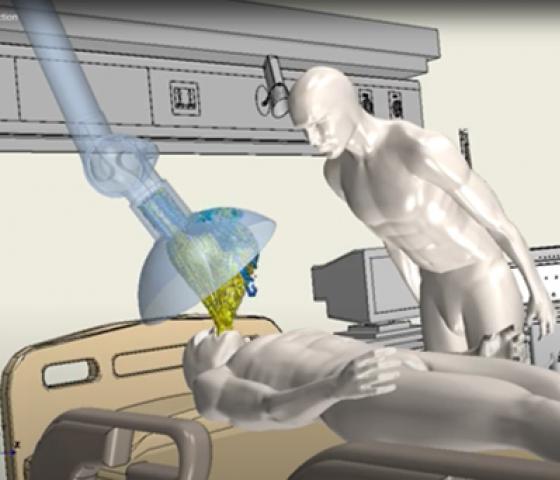

Application Hospital ventialtion

How Computational Fluid Dynamics (CFD) simulations may be used to analyse how different ventilation solutions will reduce the amount of pathogens in the air and thereby decrease spread of infection.

Finite Element Method (FEM) & Finite Element Analysis (FEA)

The Finite Element Method is a powerful mathematics based tool that can be used for prediciting the physical behaviour in a large number of engineering applications. Both mainly static problems (implicit approach) and very fast dynamic scenarios such as car crashes (explicit approach) can be solved. The main benefit is that it is possible to predict or verify behaviour long before there is a physical prototype that you can test. In some cases,a lso the test is very expensive. In some cases such as bridges or buildings, or other large objects, it is of course impossible to make physical tests.

It is also possible to simulate a large number of “what if” scenarios in a short period of time, once you have a good computer model. Simulations using the Finite Element Method are conducted in a large number industries by AFRY specialists.

We supply projects and engineering resources from our offices, or alternative on-site at your location.

Some examples of what we can support you with:

- Crash simulations

- Drop tests

- Dynamic behaviour/Eigenfrequencies

- Electromagnetics

- Fatigue evaluation

- Noise simulations

- Pipe and pressure vessel analysis

- Strength calculations

- Structural Optimization

- Thermo-mechanical behaviour

Software

We have experts in several common software such as

- Abaqus

- Ansys

- LS-Dyna

- Nastran

- Rohr2

- ... and many more.

Please ask us about any software of interest!

Application Crash analysis

Through a simulation model of the seat as well as child dummies in different sizes, lots of crashes were simulated to assess the injuries in order to create a seat that meets all testing criteria.

CAE - an excellent Engineering Tool

Reduce risks, predict behavior, and improve performance, long before you can actually test it!

Computer Aided Engineering (CAE) is an excellent engineering tool for obtaining the intended design characteristics, minimizing project risks and cutting lead-time in your project. Using simulation, AFRY enables intended design quality at a lower cost. CAE driven development optimize the performance using less expensive and time consuming physical testing. Integrating CAE into your projects will therefore minimize risk and add value to your sustainability work. With hundreds of CAE engineers, AFRY is one of the largest in Europe when it comes to CAE.

Make the right decision with deep knowledge

We use CAE methods and tools to support our clients with decision making in complete product development projects, large infrastructure projects as well as designing process equipment for a new power plant.

Reduce risks

Computer Aided Engineering (CAE) is an excellent engineering tool to obtain deep knowledge for products and processes in a short time and with no physical risks. Furthermore, by using CAE plausible risks can be predicted and avoided.

Predict behavior and Improve Performance

We often use CAE to predict product and process behaviour. By altering parameters and analyze the outcome the product and process performance are easily improved. Experience and knowledge are the keys to identify the relevant parameters.