Energy Asset Management

Successful asset management is a key to growth

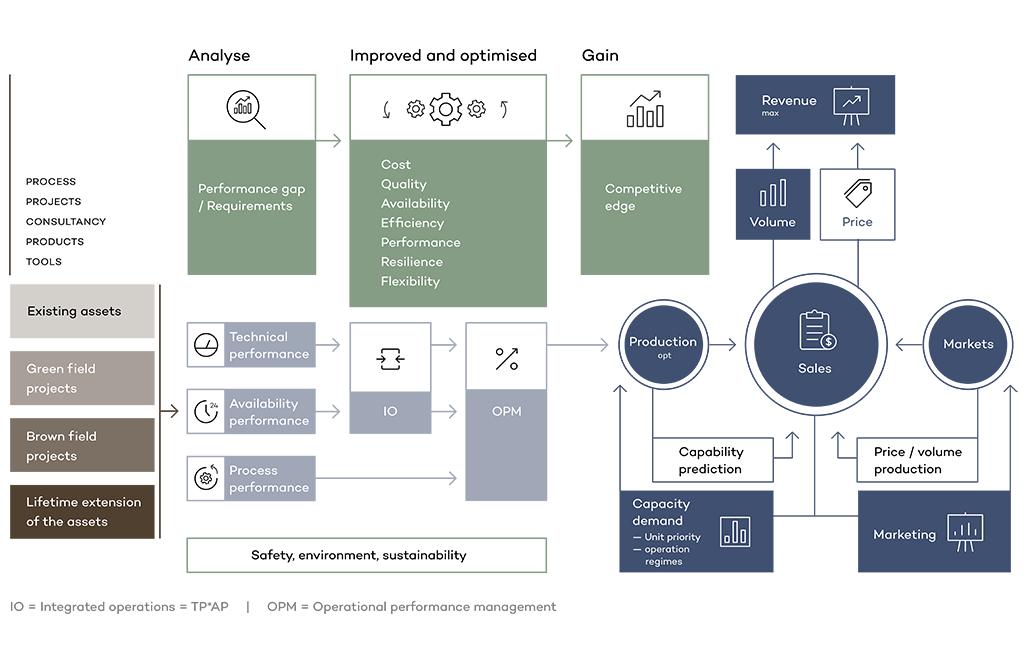

Asset management can be the single most powerful tool to improve your production and enable you to use your resources efficiently. AFRY’s Asset Management concept provides methodologies and tools for continuous improvement of your asset’s performance.

Operational excellence and continuous improvement

In many industries the competitive edge is gained through efficient production.

AFRY’s Asset Management methodologies guide includes identifying risks and defining the most successful mitigation actions, having the tools and means to improve the O&M, and providing technological solutions to boost and to make the production more flexible, helping you to achieve operational excellence.

AFRY’s Asset Management offers a holistic concept to manage and continuously improve assets. It connects performance with relevant KPIs, giving you the tools to efficiently concentrate on the key issues. The asset management concept concentrates on areas which can be affected by engineering functions; technical and availability performance. Technical Performance refers to the technical performance of the assets’ life capacity, efficiency, etc., whereas Asset Performance takes into account risks, alignment, life cycle cost, etc.

AFRY’s Asset Management concept enables you to improve the production holistically making it more efficient by reducing the execution gap. The applied methodologies identify critical assets and risks, defining what information to collect and why, analysis on most feasible improvement options and how to improve maintenance and boost the technical performance and flexibility.

Asset Management Portfolio

- Overview

- How it works

- Test and Measurements

- Process Control

- Reliability Management

- Operational Performance Management (OPM)

- Products

AFRY’s Asset Management services provide a portfolio of services to unleash your organisations’ hidden abilities and to improve the O&M from various aspects. The services and solutions focus on improving and optimising the assets holistically.

Our portfolio is divided into the following categories, enabling us to take life cycle and risk management into account from the very beginning of project development. Additionally, being able to improve technical and availability performance helps make the operations more competitive.

AFRY offers a wide range of test and measurement services for processes within energy production and industry for customers who need to verify the performance of their assets from a regulatory or a business perspective.

Process Control

AFRY’s process control unit offers state-of-the-art technology and comprehensive O&M consultation to power generation and process industry.

Reliability Management

AFRY’s Reliability Management solutions and services support you by increasing process efficiency, reducing system life-cycle costs and managing risks.

Operational Performance Management (OPM)

AFRY's OPM experts analyse improvement potential and provide the practical means to utilise your assets efficiently from technical and controlled improvements up to optimised maintenance.

Industry 4.0 is the application of technology to digitally transform how industrial companies operate. It is driven by a need to boost efficiency, become more agile in response to market unpredictability, improve quality and enable new business models.

With the development of Internet of Things (IoT), Big Data and Advance Analytics as well as with other digital solutions, companies can utilise asset usage in a more end-to-end way. Industry 4.0 opens new possibilities for immediate benefits: cost savings, a lower carbon footprint, reduced asset downtime and an increase of return on investments made to name a few.

It makes sense that companies need to continually work on the improvement and management of their assets.

Industry 4.0 challenges

Industry 4.0 is not just a onetime action, but a continuous process to start to utilise data efficiently. The challenge is to see the big picture for strategic targets and key areas. However, doing something is better than doing nothing.

Because companies lack a mature asset management strategy they face many challenges:

- Company’s strategy and other disciplines might not be linked properly to physical asset management practices.

- There is a strong need for cultural and organisational change.

- The data required for this change is not available.

Moreover:

- One does not have a tool, or synchronised tools, that are able to manage different types of assets;

- Current asset management tools are not compatible with current technologies such as big data and machine learning techniques; and

- Tools have been developed by IT and not in the design and management of physical assets.

The big question is how to utilise digital technologies in order for asset management to determine the best ways of value added from production, operation and supply chain perspectives.

What should be considered when planning to improve current asset management?

The questions we should ask ourselves to conquer these challenges are:

- Do we really know where we are?

- Do we use our resources efficiently?

- What kind of risks we are exposed to and how to deal with them?

- Do we have a clear and reasoned understanding of the best options?

- How to be prepared to possible changes in the future?

- How to monitor performance efficiently, how to define the right KPIs?

- What is critical and important and why?

- How to deal with the increasing amount of data?

Some more detailed areas where many companies are struggling, causing reduced asset performance, are related to low availability, how to retain knowledge in the organisation, what is the best way to manage ageing assets and how to get right and reliable information for decision making.

Asset Reliability and Availability

- Designed reliability vs current reliability

- Increasing % availability

- Visibility in future failures for better planning

Retain Knowledge and consistency

- Retiring Workforce

- Lack of experience to handle unplanned failures

- Inability to transfer knowledge across the enterprise

Operational Cost Management

- Ageing systems

- Energy consumption, waste, repair time, unplanned shutdowns and higher OPEX

Decision Support

- Multiple silo systems with information overload

- Lack of clear information on how to manage operations

Risk Management

In order to make the right decisions, both strategical and operational, one would need to have sufficient information. One part of making informed decisions is to understand the risks the company and operations are exposed to. Unfortunately, many risk management methodologies’ output is a risk consequence, rather than analysis on the risks root causes, giving a clear plan of how to react to them when they have been realised. Contemporary tools can make the analysis and risk forecasts, efficiently giving new aspects to risk management, not just for analysing the risk root causes, but analysing the consequences and risks over the life cycle of the assets.

AFRY offers a wide range of test and measurement services for processes within energy production and industry. We have offered versatile measurement services for over 50 years, which is why our expertise is relied upon globally.

We guarantee reliable results.

Performance Measurements

- Guarantee Tests

- Condition Testing and Analysis

- PV Testing

Environmental Measurements

- Flue Gas Emissions

- Noise Measurements

- Expert Services

Wind Measurements

- Site Mapping

- Meteorological Towers

- Reference and Performance Testing

AFRY’s process control unit offers state-of-the-art technology to power generation and process industry. Unique and sophisticated solutions are created for all kind of power boilers, steam networks, district heat networks, balance of plant, turbines etc. Process control unit services cover Balance+ technology, design reviews, operational analysis, staff training and comprehensive O&M consultation.

AFRY Balance+

- Performance Improvement Potential Analysis

- Advanced Process Control Concept

Operational Analysis

- Performance Design Review

- Performance Analysis

We bring decades of experience from a wide variety of power plant and process industry controls to the more than 50 projects that we carry out around the world annually.

Sudden equipment failures, process disruptions and inefficiencies are causing unplanned downtime, leading to billions of euros in losses across process industries, annually. In a rapidly changing environment the stakeholders are increasingly forced to seek ways to improve their revenue and margins which lead to searching for new technologies and applications to manage risks, increase efficiency, improve availability and decrease costs.

AFRY’s Reliability Management solutions and services support you by increasing process efficiency, reducing system life-cycle costs and managing risks. We develop and apply advanced reliability, availability, maintainability and safety (RAMS) analysis methods, the latest risk assessment techniques, and efficient modelling and simulation tools. We help you to concentrate where it matters most. Our ultimate goal is to secure your optimal production capacity with an acceptable risk level in a cost efficient way throughout the life-cycle process.

Our product range includes:

- RAMS and Risk Analyses

- Integrated Operations

- Maintenance Optimisation and Streamlined RCM

- AFRY Reliability Tools

- RAMS training – Methods & Tools

- KRTI 4.0™ – the Next Generation AI Platform for Operational Excellence

- SRM Smart Risk Management

- IoT and APM Integration

With Reliability Management, it is a question of appreciation and willingness: do we want to assess risks related to the system availability, safety and life cycle costs and mitigate them to an acceptable level in advance, or do we react to them after they have become reality?

Efficient production, being one of the key performance factors for a successful business, is achieved by optimising, not just individual performance of equipment, but taking into account the whole system/plant/site holistically from a Life Cycle Cost optimisation point of view.

AFRY’s asset management concept has a systematic means to analyse the improvement potential. It includes methodologies on how to improve the technical performance, optimise maintenance and manage big data to be able to combine them all, to continuously improve the production and get better and relevant data for continuous improvement.

The Integrated Operations (IO) concept combines TP and AP to optimise the production. It is a highly recommended approach to brown and green field projects ensuring that the project objectives are met, especially from the Life Cycle Cost (LCC) point of view.

The OPM concept combines the Life Cycle Cost optimisation with process improvement. Where IO provides framework for improvement, OPM provides the practical means to utilise your assets efficiently through technical and controlled improvements up to optimised maintenance.

Better performance production provides sales with a better platform to generate cash flows.

AFRY has the following products and services available to improve production:

AFRY Reliability Tools

The advanced modelling and analysis help you to achieve understanding about complex and dynamic relations between component failures and system/process key performance indicators (KPI).

Balance+

Advanced Process Control releases the execution gap by enabling more efficient, flexible, reliable production, and reducing emissions.

KRTI 4.0

Model Based – Data Driven prescriptive maintenance solution. A platform to manage your digitalisation needs by combining data management with operations.

Performance Analysis

Asset current status analysis based on testing and expert analysis for problem solving and improvement/investment options to improve current performance.

Reliability, Availability, and Maintainability Services (RAMS)

Optimising Life Cycle Cost, revealing critical assets and risks, defining data collection requirements.

SPM – Smart Plant Monitoring

Through a continuous overview of the plant data, our Smart Plant Monitoring service provides areas for improvement for the thermal process based on thorough analysis and calibrated process information.