Risk assessments

We ensure expertise and a systematic approach on risk assessment

A comprehensive risk analysis enables you to see the correlations and provides you with important information for decision making on the critical areas to improve your operations and safety systems and solutions.

Our certified safety experts with a technical background understand the features and functionalities of the industrial processes, machinery and sites that ensures the best competence in understanding of correlations and impacts of different types of hazards.

With systematic approach on risk assessments

- requirements set by legislation and authorities are fulfilled,

- status of plant / processes / machinery will be known and safety improved and

- awareness of process, machinery or occupational health and safety (OHS) related risks enhanced and clarified

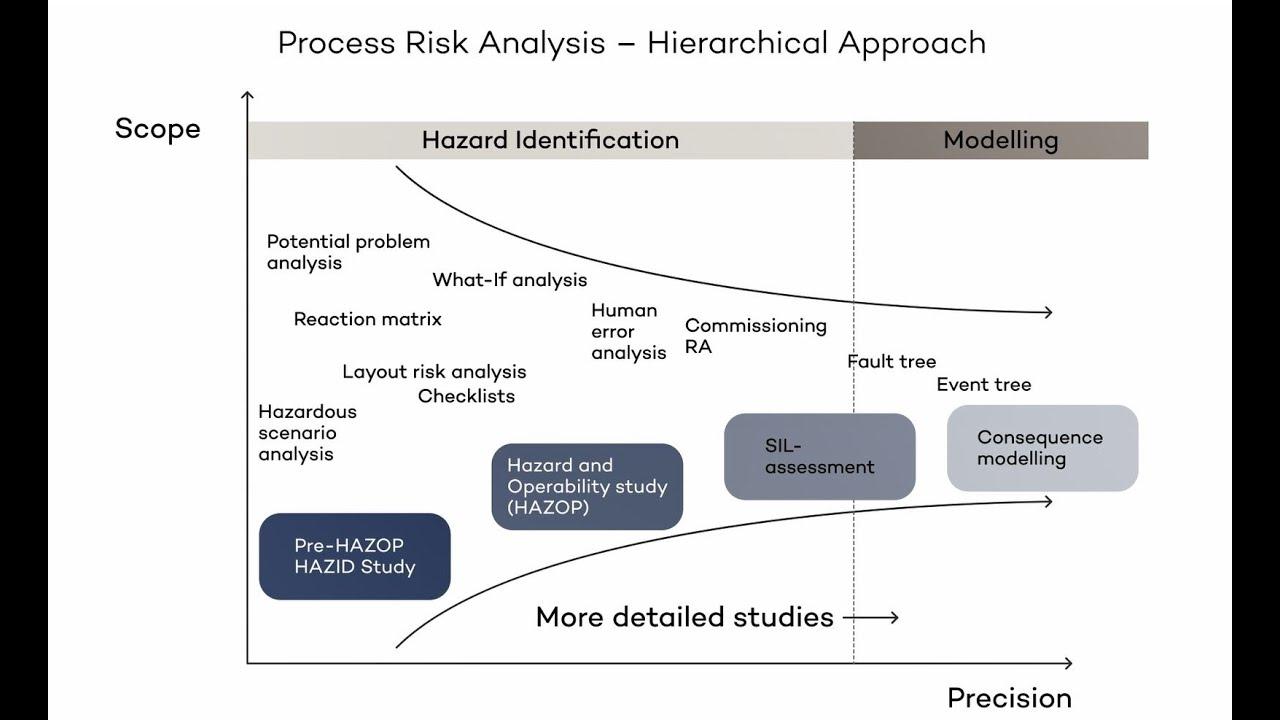

We use various standardized risk analysis methods in identification and assessment of process, machinery and OHS related hazards and risks, i.a.

- Hazard Identification (HAZID) / Hazardous Scenario Analysis (HAZSCAN)

- Hazard and Operability Study (HAZOP, IEC 61882)

- Risk assessments of machinery and/or assemblies of machinery (ISO 12100)

- Human Error Analysis (HEA)

- Consequence analyses, Quantitative Risk Analyses (QRA)

- Bowtie analysis

- Interface Hazard Analysis

- Functional safety related risk analyses

See below an example of a hierarchical approach on process risk analyses.

Contact us

Anna Savunen

Head of Global HSE Services

Interested in our offering? Contact us!

Contact Anna Savunen

For sales enquiries, please complete this form. For all other enquiries, please visit our

office and contacts page here.