From threads to tactics: weaving sustainability into the textile value chain

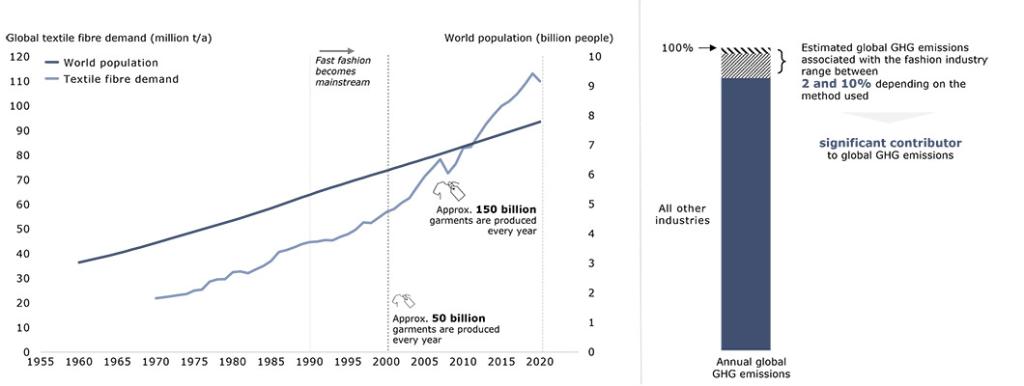

The demand for textiles has more than doubled over the last 30 years.

This change has mostly been driven by population growth and the increasing share of middle-class citizens.

In the 1990s, fast fashion became mainstream, resulting in cheap products that were not meant to last. This further increased the environmental burden caused by the textile and fashion industry. Today, this sector is one of the most polluting industries, responsible for up to 10% of all humanity’s carbon emissions.

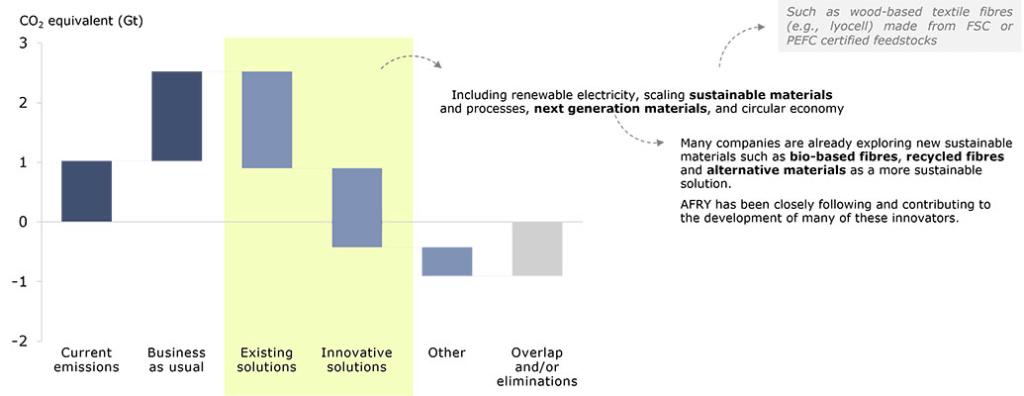

In more recent years, consumers have become more aware of the environmental impact of their clothing, which has put pressure on the industry to improve its environmental footprint. This trend has also been reflected in their buying habits, which in turn has increased the pressure on brand owners and retailers to commit to more sustainable practices. Thus, the fashion industry is searching for solutions to reduce its environmental footprint and reach net zero by 2050.

Challenges and opportunities in sustainable textile value chains

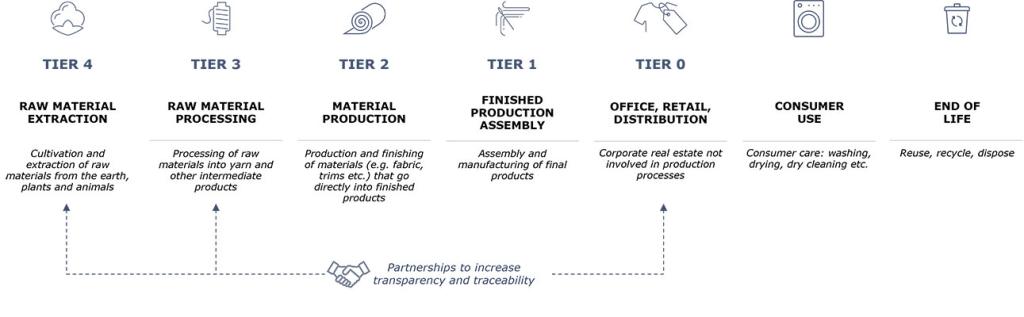

However, finding solutions for such complex problems as sustainability issues is not straightforward. The catch is in the complexity of the textile industry value chain. This value chain is often described in Tiers covering the process from raw material to the finished product. Tier 4 covers raw material extraction from earth, plants, or animals, while Tier 3 comprises the processing of raw materials into yarns and other intermediate products. Production of materials, such as fabrics, falls under Tier 2, while assembly and manufacturing of final products are described as Tier 1. Tier 0 covers the retail and distribution of the finished products. The number of operators in the value chain increases heavily from Tier 4 to Tier 0, resulting in a long and complex chain with thousands of operators spread across the globe.

The complexity of the textile value chain makes it difficult to track and trace the product from its feedstock to the end of life. Lack of transparency and traceability is often a common challenge to the whole industry, causing delays, errors and increased costs. It also makes it difficult to have control over the sustainability issues in other parts of the value chain. Some opportunities for reducing the environmental impact in the textile and fashion industry exist in developing sustainable and next-generation materials. In recent years, many companies from different parts of the value chain have announced partnerships to speed up the time-to-market for these new solutions.

Partnerships can offer an opportunity to enhance transparency through interactions across boundaries and sectors, and those can be aimed at bringing change at the company, industry, supply chain or societal level. The core of effective cooperation is trust, openness and knowledge sharing between the team members. Combining different viewpoints creates a shared understanding, which increases resilience to risks.

Strengthening intercompany collaboration

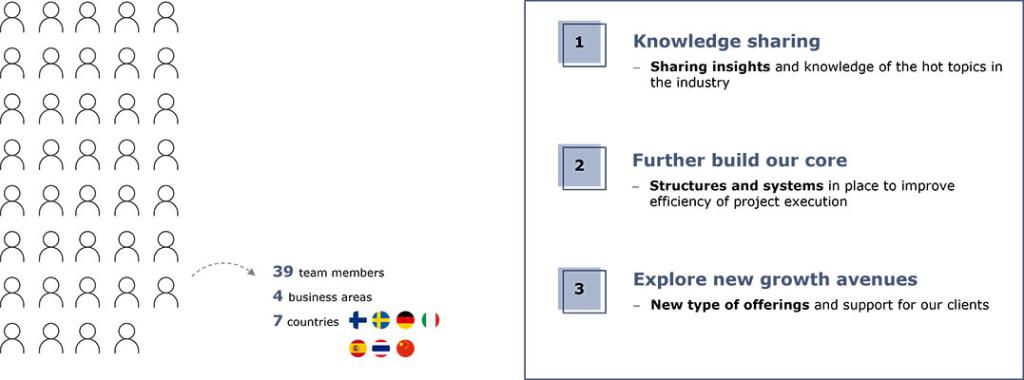

A practical example of an intercompany partnership is AFRY’s Textile Tactics Team, which was founded in 2021. The aim of the group was to set up an internal network of AFRY’s subject matter experts in the field of textiles. The Textile Tactics Team shares knowledge and expertise while collaborating and strengthening AFRY’s engineering and management consulting offering in this growing industry. The Team meets virtually every quarter to go over the hot topics in the field of textiles, share relevant insights between the team members and plan how AFRY could further develop its offering for its clients within the textile industry. Most importantly, these meetings represent a chance to share knowledge between people and business areas within AFRY.

As of February 2024, the Team is comprised of 39 experts representing four different business areas and perspectives from Finland, Sweden, Germany, Spain, Italy, Thailand and China. Initiatives like the Textile Tactics Team give AFRY the potential to be more resilient towards the disruptions within the business and to seize the opportunities coming its way.