AFRY Balance+

A unique approach to enhance performance

Comprehensive consultation and solutions to Plant Energy and Performance Improvements

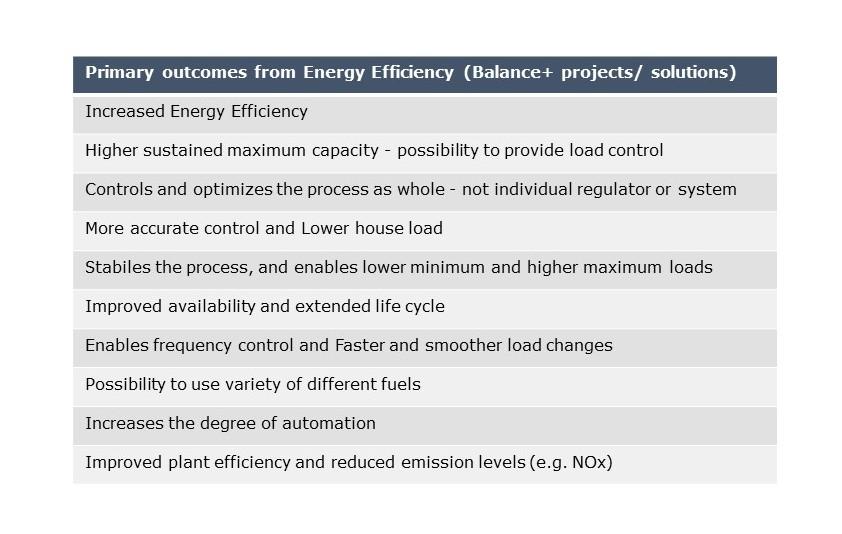

Balance+ is a combination of expertise and solutions for achieving energy efficiency, better performance, and improved reliability and availability. Balance+ is distinctly different from traditional controls and from other APC (advanced process control) solutions. It improves processes making them more efficient, flexible, and reliable, also reducing emissions.

Balance+ is a solution to these issues:

- Unstable solid-fuel boiler operation

- Low availability of main boiler and energy supply

- Low efficiency of main boiler operation

- Boiler operation requires a lot of manual interventions by operators

- Boiler load cannot be adjusted as fast as would required to produce the right amount of heat and power

Imparting expertise to every part of the process

Balance+ is a process-based concept and solution to handle long-term changes, fuel quality changes, and process disturbances. It can be used in every type of boiler process, feed water control, steam temperature control, and combustion power controls, expanded to handle all of the process steam network control requirements. Balance+ has thermodynamic modelling, adaptive calculation models, and a combination of solutions.

Advanced control solutions for boilers and industrial processes

AFRY's solution is based on physical adaptive process models and tens of unique algorithms, which provide higher efficiency, longer asset life cycle and lower emissions than conventional control solutions.

Balance+ has PI controllers with intelligent limitation logics, calculations, self-learning functions. It is distinctly different from traditional controls and from other APC (advanced process control) solutions.

This technology is widely used with industrial power boilers and it leverages historical data. All the main parameters are self-learning when the process can find the optimal operating point with the best efficiency and reliability.

Balance+ can be implemented directly in DCS, or on a separate standalone platform interfaced with the DCS. Implementation is already done for Siemens, ABB, Honeywell, Emerson, Valmet, GE, etc.

Deep technical know-how and industry knowledge

AFRY has a strong track record with proven results from across the globe, supported by the Finnish Funding Agency for Technology and Innovation, TEKES, and patented solutions. At AFRY, we drive continuously to improve our own and our client’s operations making the world a better place in the changing market conditions. We improve your existing assets with advanced control solutions. It is not a plug-and-play but a comprehensive customized solution package using AFRY’s unique technology, expertise, and experience from the processes and business.

Key Characteristics

- Advanced control solution for boilers and industrial processes

- Optimized production and performance, increased boiler life cycle, less emissions

- More accurate and more stable control, robustness to controls

- Combination of unique solutions to every part of boiler process

- Unique solutions also to BOP, emission controls, steam networks, parallel operation of boiler and turbines etc.

- We improve the processes – boilers and industrial processes - making them more efficient, flexible, reliable and reduce emissions.

- Distinctly different from traditional controls and from other APC (advanced process control) solutions

- Balance+ is not tuning the existing software, instead reprogramming the software

- Other products are built on top of the old solutions when same root causes exists

- Process-based concept, self-learning features and history data use

- Main variables based on adaptive calculation models, thermodynamic modelling etc.

Strong track record with proven results: Solutions are in more than 80 boilers worldwide with significant improvements

Intelligent usage of PID controllers

Most of the control response depends on the process-based calculations.

Fuel and air controls

- Load control by using a sophisticated thermodynamic model-based concept

- During loading and unloading boiler's inner energy compensated

- Intelligent heat value correction

- Intelligent fuel distribution and combustion optimization for optimal bed behavior

- Combustion optimization with grate, BFB, and CFB boilers

- Fuel pocket level control

- Accurate and right fire/air balance control and air distribution primary, secondary, and tertiary

- Adaptive air factor to learn the fuel moisture content change

- CO and NOx optimization

Steam and Electrical load allocation concept

- Physical calculation-based concept

- Accurate HP, MP & LP header control

- Priority of steam producers

- Production optimization inside of the control concept

- Sophisticated operation with multiple turbines and boilers

Patented drum-level concept

- Disturbance handling and feedwater cycle optimization

- Reduced power consumption

Patented model-based steam temperature control

- Advanced thermodynamic model-based control concept with self-learning functions

- Sootblow actions learning function

Balance+ has provided significant benefits to numerous plants, e.g:

- 2% higher plant efficiency

- 10% higher sustained production in maximum load

- 3% higher sustained production with biofuel-fired units

- 40% lower NOx formation

- 50% lower minimum load

- 10% reduction in house load

- Improved plant flexibility (4% ramp rates)

- Steam venting and condensing losses with the steam network were reduced significantly

- Reduced oil consumption

- Reduced consumption of ammonia/urea with optimized combustion and NOx control

- 30 – 40 % reductions in consumption

- Possibility to provide primary and secondary frequency support with accurate control and minimized plant stresses

Interested in our offering? Contact us!