Plastic Waste Free World 2023: All hands on deck to put an end to plastic waste

Atlanta, Georgia – October 11–12, 2023

The 2023 Plastic Waste Free World Conference & Expo, held in Atlanta last week, was a window into the flurry of activity happening behind the scenes as plastics, chemicals, packaging and waste companies, as well as research and development organisations, race to find ways to minimise the growing problem of plastics pollution.

The overarching themes of the presenters were related to educating consumers on proper disposal, improving recycling infrastructure, waste and packaging policies, chemical recycling and bio-based plastic alternatives. Some promised the hope of chemical recycling to return hard-to-recycle plastics to their chemical and fossil-based components. Others offered new ways of mechanical recycling. A smattering of new materials producers showcased pilot-scale samples of their corn- or starch-based plastics, which would compost if littered.

How do we phase out plastic waste?

The challenges among these offered solutions are many. In order to improve the recycling of plastics, we must educate consumers, who are overwhelmingly confused about how to navigate which materials can be recycled in their local curbside systems.

Globally, less than 15% of the plastics generated are collected for recycling. Of that, losses and rejected material are significant. Therefore, we must also redesign plastic packaging, which requires major shifts in thinking throughout the plastic packaging value chain – no easy feat.

While bio-based plastics as replacements for fossil-based plastics are enticing due to the promise of lowered carbon emissions and compostability, the current scale of production is minuscule compared to the plastics industry. The difference in the order of magnitude of single-use plastics that we need to phase out compared to the scale of these new materials is mind-boggling.

Enter fibre-based packaging for the win!

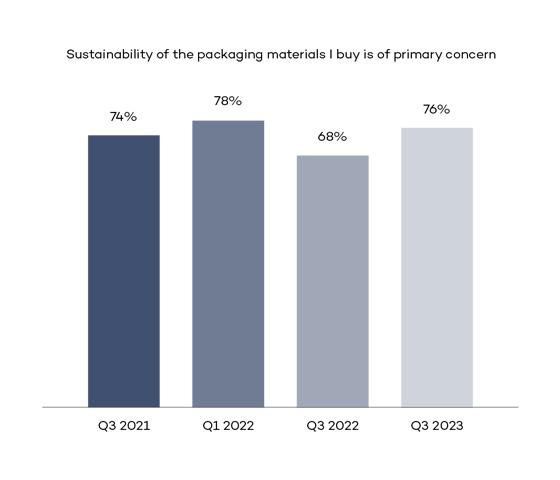

Consumers increasingly report that they perceive fibre-based packaging as more environmentally friendly than plastics. Many life-cycle assessments confirm that the carbon footprint of fibre-based packaging is significantly lower for fibre-based packaging than plastics.

With single-use packaging reduction targets, extended producer responsibility schemes, single-use plastics bans, and net zero targets by brand owners, demand for fibre-based packaging is on the rise. AFRY estimates that there is over a 3 million tonne demand growth in cartonboard, sack, kraft and moulded fibre by 2030 in North America alone.

However, the role of functional barriers in enabling fibre-based packaging to meet performance criteria for food contact packaging cannot be overlooked. While fibre-based packaging is recyclable, non-toxic and can be biodegradable, they have a low resistance to water, grease and gas without barriers. Most food and beverage packaging contains plastic barriers to adhere to strict barrier criteria for oil, grease, water and oxygen. Bio-based solutions enable a shift away from these plastic barrier coatings, which consider both the carbon footprint and end-of-life considerations of the packaging.

Bringing new materials into the fold

New materials, represented at the Plastic Waste Free World conference, showcased many prototypes of products, from cups to straws, completely out of their bio-based materials. However, it seemed that the application as a barrier solution on fibre-based packaging was not on their radar.

Collaboration across the packaging value chain is critical to expedite the scale and commercialisation of these new materials as a barrier solution to fibre-based packaging. Only through collaboration can these new materials overcome the hurdles of scaling, overcoming the steep learning curve in adoption and commercialisation.

If new, bio-based, biodegradable and compostable materials can be applied as a barrier solution to fibre-based packaging for food contact applications, the demand opportunity for these materials could be large. AFRY’s presentation to the Plastic Waste Free World conference aimed to highlight this point and offer support to any player in the packaging value chain who is ready to capitalise on the large opportunity in the transition ahead.

For more information on the status and role of barrier solutions and the packaging market, reach out to AFRY. We’re #makingfuture together.

Bioindustry Management Consulting

Bio-based alternatives and a circular economy approach have increased in their importance and are becoming the new norm. To survive and flourish, industries and companies need to adapt and innovate at an ever-increasing rate. This generates a growing and exciting market for our consulting services.