Why proper maintenance management process is an essential lever for production optimisation

Rather than “go and fix the machine” in firefighting mode, attention to the details of maintenance management processes are the enablers for world class performance.

We have done many diagnostics in various industries looking at the maintenance function. To understand why maintenance performance is low when reviewing the results, be it in terms of technical downtime, lost production or high costs, the maintenance business process needs to be thoroughly analysed. It is the process that needs to be managed to achieve the desired results.

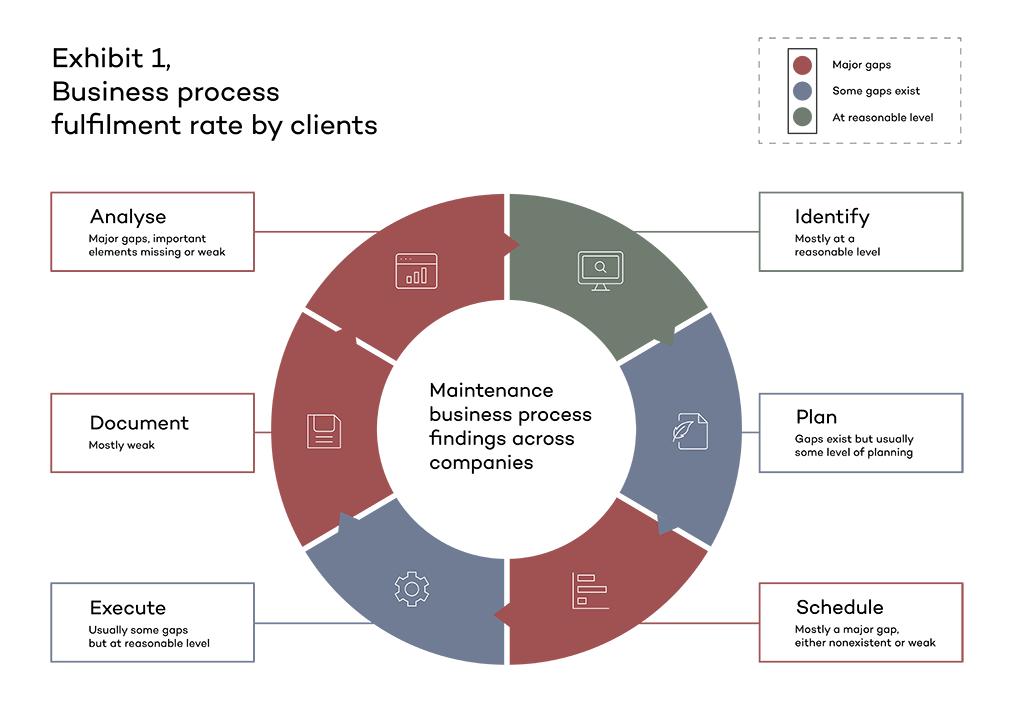

In our diagnostics we find that companies across industries show similar weaknesses in some parts of the process and are at better levels in others. However, the business process needs to be understood as a circle with each step depending on the quality of the previous one. If work is not prepared properly, execution will suffer either in quality or in efficiency. If documentation is weak, analysis will be more difficult and organisational learning will be hampered.

Scheduling is one aspect of maintenance that is usually very weak in most companies that we have analysed. This part of the process is the weakest link in most companies, on average only about 25% complete against a defined set of criteria. Often the importance of scheduling is not properly understood. There is a strong link between scheduling and machine reliability, because proper scheduling ensures that priorities are set correctly and available resources are utilised accordingly.

Analysis, which builds the cornerstone of continuous improvement, is the other aspect of maintenance where we usually find major gaps, on average only one third complete. Often major failures are not investigated well enough and root causes not identified or corrective action is not taken timely enough. This results in the failure to be repeated. A set of suitable key performance indicators is often missing as well, leading to weaknesses in the business process not being recognised and rectified.

After the gap analysis in our diagnostics we find considerable potential of up to 50% reduction in technical downtime, and therefore increasing total available time for production. We work together with our client companies to close the gaps and to implement maintenance processes and systems that support their respective production abilities better and enable a higher contribution to the bottom line for their companies.