Circularity transforms the use of plastic

More plastic than fish in the ocean – in 30 years this could be a reality if we do not change the way we consume plastic. A step in the right direction is to address plastic packaging and the waste it generates. With the support of ÅF, H&M has developed a circular strategy as the basis to transform all the company’s packaging.

Cheap, durable and water repellent, plastic is a core pillar of the global economy. But the negative impact of our dependency on plastic is becoming more apparent. Oil-based plastics are produced by a finite fossil resource that causes greenhouse gas emissions during both the production and incineration phases. Globally, less than 15 percent is collected for recycling. Instead, the plastic often end up in nature, which results in worldwide extensive impact on the environment. In countries with inadequate waste management systems, plastic waste is being dumped in open landfills and can cause harm when environmentally hazardous substances leak into seas and streams.

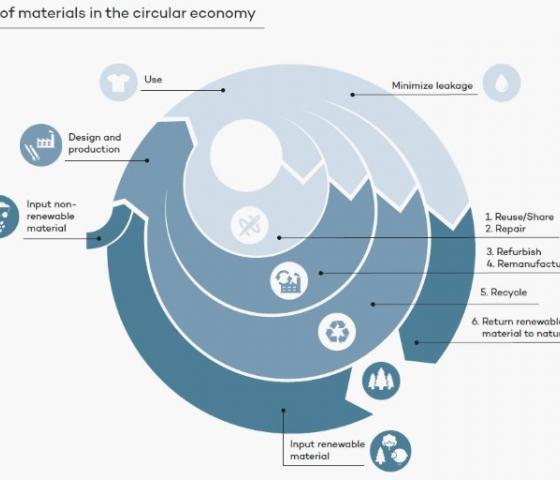

To achieve change there is a need to move towards circular systems as defined in the circular economy. This means minimising input of raw material and generation of waste as well as keeping products and materials circulating with their highest value for as long time as possible.

”From a sustainability perspective, ideal would be to get rid of all ’unnecessary’ packing, to reuse as much as possible and to ensure that packaging that can’t be reused, is recycled instead”, says Carolina Togård, sustainability consultant at ÅF, who has developed the pre-study and the strategy together with H&M.

Reuse is crucial

Not until the products are fully worn out, recycling is used as the final step – therefore, manufacturers need to consider the whole circular system in the early designing phase of products and packaging.

One company that strives to increase their circularity throughout the entire organisation is the global fashion giant H&M Group. With more than 170,000 employees in 70 countries, H&M Group is one of the dominant actors in the clothing industry. In 2017, they launched an ambitious strategy to become climate positive and take action towards circular material flows for textiles. Now, packaging is the next important area.

”On a global scale, the material flows are very linear today. For H&M, it is particularly problematic at the customer end. When the packaging ends up in the hands of our consumers we lose control over it and we can not guarantee that the package in managed in a good way”, says Cecilia Brännsten, Environmental Sustainability Manager at H&M.

To increase control of the flow of materials, ÅF was commissioned to develop a circular packaging strategy for all packaging used by H&M globally – including consumer packaging as well as product and transport packaging. Some of the main challenges highlighted were the increasing online shopping and the varying recycling opportunities in the different markets.

Selecting materials is complicated

The project was initiated with a prestudy of H&M’s use and consumption of packaging and the allocation between different types of material. For example, ÅF surveyed the proportion of material that was environmentally certified, recyclable and compostable. The analysis covered the packaging design, choice of material, packaging routines as well as end-of-life management.

ÅF also analysed innovative packaging designs currently available on the market, global regulations, trends related to plastic, alternative materials and the challenges in creating a circular system.

”When considering the material of a product, a good option is to use recycled bio-based materials that are recyclable and bio-degradable if it ends up in nature. One example is packaging produced from recycled paper, but the challenge is that it is sometimes more expensive than virgin paper and it can be difficult to find a high-quality recycled paper. Degradable bioplastics are marketed as a more sustainable alternative to conventional plastics, but most degradable plastics currently on the market require industrial composting. The plastics do not degrade if they end up in nature”, explains Carolina Togård.

Circular design as part of the strategy

Reusing and recycling are two of the four focus areas in the work lying ahead for H&M, to move towards a circular system for its packaging.

”Recycling and reusing will be guiding principles in the design of all our consumer packaging. We want to make it easier for customers to recycle or reuse the packaging. This is called circular design and it is an important part of our effort to achieve a circular packaging system. We are also working to create better opportunities to sort materials at warehouses and in stores”, says Cecilia Brännsten.

The strategy offers a holistic approach in transforming packaging, but also an opportunity to drive positive social change.

”The most obvious positive impact is that we reduce our resource consumption and increase control of consumer facing plastics and other packaging materials for customers. We also gain a better insight of global legislation on plastic, and how we can contribute to ensuring we are moving in the right direction in the markets where we operate”, says Cecilia Brännsten.