Decarbonisation Study for Process Industries

For assessing and identifying GHG impacts of your industrial unit or process

AFRY's Decarbonisation Study for Process Industries defines the roadmap to GHG emissions reduction by identifying and prioritizing decarbonisation measures with impact and implementation cost analysis. It applies to any process industry operations, from single units to entire production processes.

Globally there are still several industrial sites using a large share of fossil fuels like natural gas and fuel oil as energy source. Thus the potential for reduction in GHG emissions is huge. During past years AFRY has conducted several decarbonization studies with excellent results.

Decarbonisation study is done for the existing plants. AFRY has experience with old (over 50 years old) mills to the newest and the most modern mills globally. As a result of the study, Client will receive a concrete list of actions to achieve the decarbonization targets. AFRY has long experience in energy efficiency studies that can be included as part of the decarbonization study. AFRY’s wide and long expertise in complex mill environment is key to understanding the impacts of the GHG measures for the entire mill.

AFRY also offers GHG impact assessment for the investment. This is a simplified version of the decarbonisation study and is aimed for the investment project. Greenhouse Gas Impact Assessment can be done at different stages of the project: pre-feasibility, feasibility or pre-engineering study. Impact assessment shows the sources of greenhouse gases and gives a good understanding of the impact of the planned investment on the mil’s GHG emissions.

AFRY's comprehensive deliverables for Decarbonisation Study include the following:

- Current status and achievable targets

- Scenario/measures required to reach the targets

- Costs and benefits

- Total CAPEX of the measures to reach targets in alternative scenarios

- Implementation plan and schedule

There are 3 scopes defined by the GHG protocol. Identification of GHG emissions is usually done based on direct (Scope 1) and indirect (Scope 2) GHG emissions.

At AFRY you will find a unique mix of sustainability specialists with long experience and experts within all industrial, digital and infrastructure branches, in 40 countries all over the world. AFRY offers a combination of vast engineering expertise, deep competence in environmental sustainability services as well as management consulting on strategies and roadmaps for business development.

With an innovative mindset and a genuine interest in finding technically and economically the most feasible solutions, AFRY creates value and improves business performance in partnership with Client.

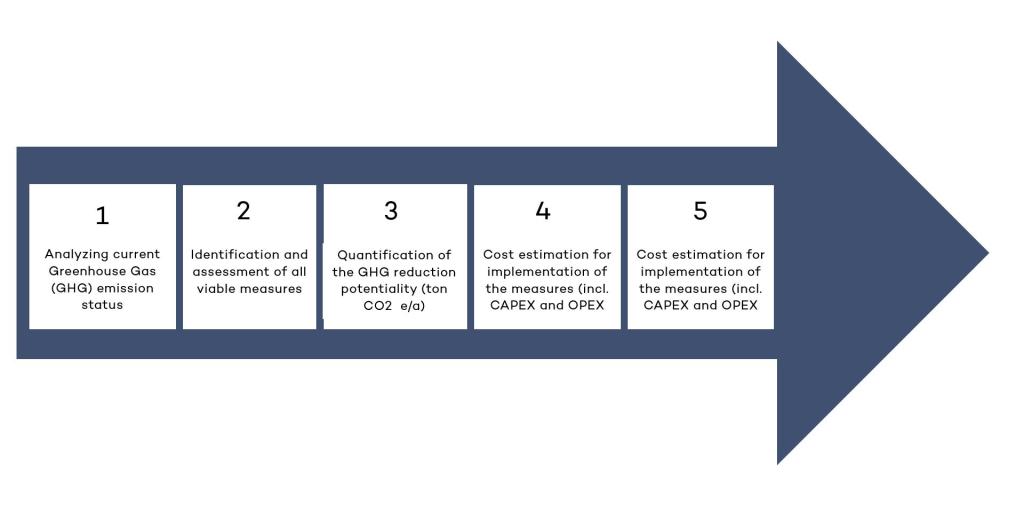

Assessment is started by selecting the target operations, varying from single process unit to entire plant operations. First, AFRY does a review and determination of the present Greenhouse Gas (GHG) emission status.

Second step is the identification and assessment of all viable measures that impact GHG emissions. After this, quantification of the GHG reduction potentiality (ton CO2 e/a) is calculated.

To define the roadmap estimation of cost for implementation of the measures (CAPEX and OPEX) is done. Based on the analyzed potentiality and investment cost the proposal for prioritization of the measures is done.