To reach your goals, be conscious and careful about how you measure your performance

Written by Jakob Redlinger-Pohn, Alexander Pohl, William Isaksson, Lea Pauline Schalk, and Stefan Kucher

Key Performance Indicators (KPIs) measure the business and operation performance, but KPIs are frequently ill-defined and non-suited for reaching the envisioned goal

Having clearly defined goals, performance measurement quantifies how well these are met and triggers actions for adjustment. Performance measurement and strategy are tied to each other, but both need to be handled with care. Key Performance Indicators (KPIs) for measurement can also mislead or invoke counterproductive actions. One of the dire consequences of inappropriate KPIs is unfocused processes. These have high waste levels and are incapable of adjusting to the macroeconomic changes that we are facing.

The rule in defining KPIs is to keep them SMART: Specific, Measurable, Attainable, Relevant, Timely. A simple rule which is often hard to follow. Common problems found across businesses that counter the KPI effectiveness include:

- The use of financial targets and production goals at the shop floor for operations control, where, for example, quality of the running production process is needed instead

- Misguidance by overemphasising the individual department performance whilst missing the connection to overall business success

- Reporting of past performance only (known as lagging KPIs) instead of using actionable KPIs that allow for a fast intervention and production adjustment to avoid waste (known as leading KPIs)

- KPIs defined by the availability of metrics and indicators instead of being defined by their suitability to inform about the process performance

An example that we recently spotlighted is the case of maintenance departments that only measure the outcome of their work but not the process steps that lead to the result. Costs and unplanned technical downtime are the often tracked KPIs, but both indicators are lagging in time and only measure the overall result. Without further analysis, these KPIs are not actionable and do not support continued improvement. KPIs that measure how well the process is followed are needed to identify shortfalls in the maintenance process.

The problem with performance measurement is that it cannot measure all that is needed, whilst what is measured can evoke unintended actions. Performance measurement is, however, essential to tracking business performance and production operation quality, as well as enabling continuous improvement. The question is: how to do it best?

Involve all stakeholders and pair process understanding with business targets when designing KPIs used for control on the shop floor

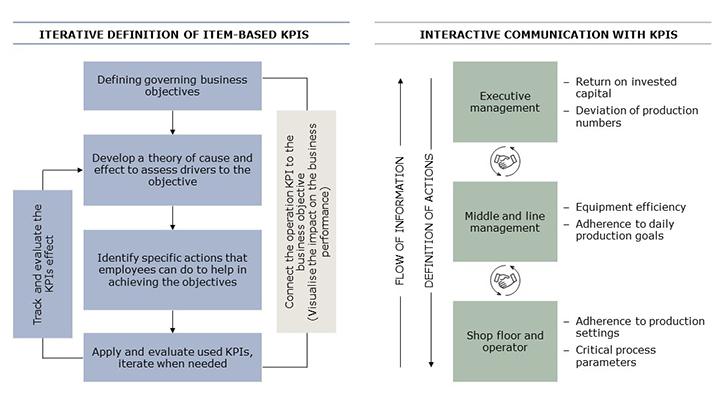

SMART KPIs need to be defined in alignment with the business objective and need to support the operators in their actions to keep the process efficient and reliably running. It is thus important to not establish KPIs simply top-down but to include operators in the design phase and iterate the result, as visualised in Figure 1, left panel.

Executive management defines the governing business objectives, which are translated into KPIs by establishing a cause-and-effect theory. In the process industry, the operational theory of cause can be established using the process flow chart or pipe and instrumentation flow diagram. Similar process flow charts should be developed as a KPI design basis for manufacturing and (internal) services, such as sales, procurement or customer relations.

Specific actions for the operator are defined from the designed KPIs. The effectiveness of these actions is tracked, and they are, along with the KPIs, subject to evaluation and redesign should they be inadequate to meet the business objective. The best is to plan for frequent reviews of the used KPIs.

Additionally, tie the KPIs to the business's success. Indicators in monetary terms visualise the personal and departmental impact, for example, money saved by waste avoided. Money raises concern, and the direct impact on profitability is a clear value and less abstract than the amount of additional production. The connection of operations and shop floor KPIs to business success helps to counter silo actions that only benefit departmental numbers but are detrimental to the overall business performance.

KPIs are fact-based and informative and must be communicated clearly to the workforce in order to avoid conflicts. Debates about KPI correctness and room for interpretation about the KPI logic counter the effective use of KPIs and must be avoided by design. The aforementioned integration of all workforce levels in the KPI design evokes trust in the KPIs. Further, display the KPI definitions, for example, as footnotes, in the daily meeting reports to counter ambiguity.

Figure 1, right panel, exemplifies KPIs appropriate to the level and their role in communication between the levels. In order to define actions against deviations, managers need accurate information, which is provided in daily shop floor meetings and cycled up to middle and senior management. Adherence to production settings and standards is cumulated to efficiencies and production goals. Deviation from planned production can thus be traced back to production problems, and measures can be taken timely. It is important to embed the flow of information and the definition of actions into communication that provides understanding on all levels. This fosters the acceptance of proper KPIs at all levels and counters playing a numbers game.

Visualisation of the KPIs is thereby an essential tool. KPIs should not be solely collected in tables but visualised, for instance, on screens in the control room. The use of colour schemes (red, yellow, green) aids readability and quickly informs about the KPI status, which enables timely actions.

What are the key takeaways to have in mind when designing KPIs?

Managers that evaluate the suitability of their KPIs and redesign KPIs to move towards optimised processes should keep in mind to:

- Define KPIs in collaboration with all stakeholders

- Utilise flow charts and process maps to identify suitable KPIs

- Define action plans and track the effectiveness of these and the KPIs

- Tie KPIs to business success

- Define KPIs clearly, without room for interpretation

- Communicate KPIs and action plans (cause and effect) across all levels

- Visualise KPIs for easy tracking and monitoring

AFRY advises on the design of KPIs based on proven strategies. We join operators, engineers and managers and guide the KPI design process along process flow charts. Together, we identify the success factors which are aligned with the business objective and define from those the KPIs that enable process performance and improvement. We take care of the KPIs and actions' sustainable implementation in your operations so that they become part of daily routines, which is essential to achieve full operational potential.