Transforming Pulp & Paper Manufacturing - Digital Solutions Addressing Real-World Challenges

For many years, the pulp and paper industry has been teetering on the brink of the next industrial revolution: digitalisation or Industry 4.0, how you want to call it. While this topic has been discussed extensively during the years, recent developments have transferred digitalisation from theory to reality within production operations. There is now evidencies that this transformation will be a game-changer, offering solutions for efficiency, cost reduction, decarbonisation, and sustainability— responding to the major challenges presently faced by the industry.

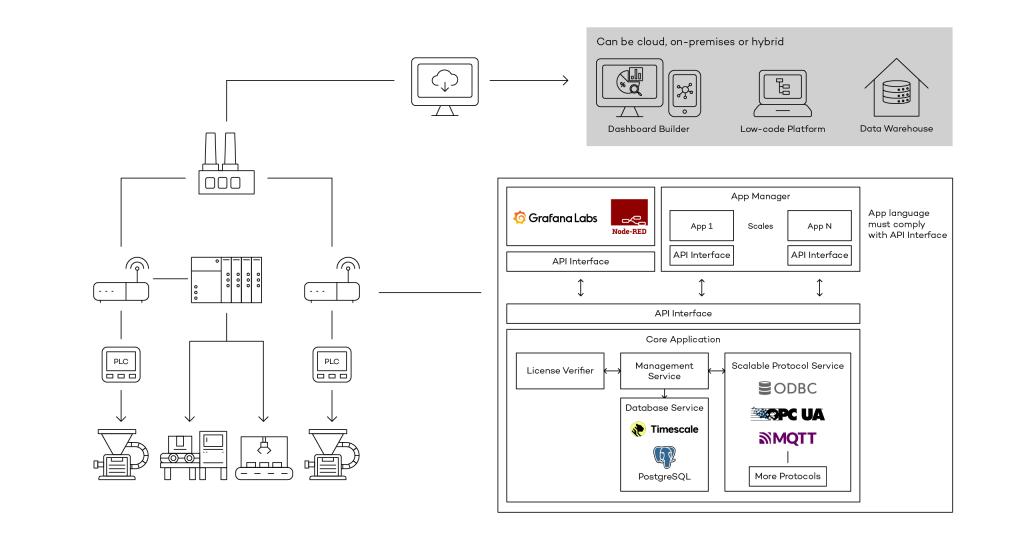

Organisations increasingly populate control rooms with set of software and applications running either on local hardware or cloud environments created by various software providers. Various digital solution providers have seen the use digitalisation as an opportunity to generate new services and retain customers. They encapsulate their knowledge in digital applications by linking their areas of expertise with diverse business processes, allowing for the generation of very specific and narrowed use cases. The use of technologies, like Internet of Things (IoT), enables the deployment of locally installed devices to transmit data to the cloud to provide SaaS models, regardless of the client's IT or OT infrastructures.

We have also found that often applications run on local hardware, generally without any connection to the organisations’ IT systems, populating dashboards and operating screens to control rooms where operators can see visualisations of specific application results. Often, through these applications, vendors can create dependencies, making it very difficult, if not impossible, for industrial operators to switch service provider without losing historical data or making systems incompatible with third-party applications and systems.

This way of implementing independent applications and software solves short-term specific needs but lacks a holistic, long-term digitalisation strategy.

Navigating the Complexities of Digital Transformation: Key Considerations for Organisations

What dependencies we create with specific solution provider? How does licensing cost grow aligned with my growing needs? Who owns the data processed by the application? How can data be made accessible for other apps or dashboards? How can I manage information flows transparently? Can apps be adapted to my specific use case requirements? The responses to all of these questions should meet the organisation's long-term needs and expectations.

Besides integrating third-party softwares and applications, organisations often need to create their own digital solutions. The expertise of the center's staff must be converted into use cases and turned quickly into reality. These in-house applications demand technologies that are challenging to merge with traditional data from control systems, like web data, IoT sensor data, or external systems. For instance, if we want to calculate our electricity cost, we may want to have data from the electricity market. If we have a solar panels installed to produce electricity, we might need the weather forecast to estimate our own power generation and therefore, according to our production planning, estimate our power demand from the grid. How can we merge this external information with our data analysers that are in the control system or in the third-party software?

Organisations are now seeking to explore Artificial Intelligence AI-based solutions for improved process control and decision-making but don’t know how to put it in practice. Common concerns in this development include the unknown costs of development, data integration possibilities, swift deployment, and scalability possibilities.

In our vision, some of the fundamental pillars on which a digital strategy for pulp & paper mills should be based are:

- The digital infrastructure should start small initially to adapt to the specific present need but can scale progressively as the organisation's needs to grow.

- Through a single source of information, we require an environment where all administrative (IT), operational (OT), and engineering (ET) systems, as well as external data sources, are interconnected, putting this information at the service of continuous improvement.

- Digitalisation should not create dependencies on vendors. The use of open-source tools eliminates these dependencies while minimising licensing costs.

- An environment where the knowledge of vendors and third-parties can function properly, but where the organisation maintains total control over the infrastructure and data flows, must be established

- Ability to develop in-house solutions and the possibility to implement those smoothly to secure quick return on investment. In this aspect, the use of low-code or no-code programming tools allows many people within the organisation to create and contribute on application creation.

Empowering Your Business by Minimising Dependencies, Costs and Maximising Control

Digitalisation should not create dependencies on suppliers. You can avoid supplier dependencies through open-source tools, ensuring full organisational control over infrastructure and data. Contribute to an environment where supplier knowledge can function, while also permitting rapid development of in-house solutions. The use of low-code or no-code programming tools allows a wide range of people within the organisation to create applications. Our AFRY Smart Platform addresses these needs, providing an open-source, technology-agnostic platform with low-code tools for data storage, programming, visualisation, analysis, and advanced process control.

Bridging Pulp & Paper Industry Expertise with Advanced Digital Solutions

To address the above-mentioned aspects, AFRY has created the AFRY Smart Platform, an open-source platform with low-code tools that is technology-agnostic, allowing for data storage, low-code programming, visualisation, information analysis, and advanced process control implementation.

AFRY has over 60 years of accumulated experience in the pulp & paper industry, with a unique combination of process specialists and multidisciplinary engineers, providing real value to our clients in all types of studies, implementation projects, and daily operation of pulp & paper mills.

Part of this experience and knowledge has been embodied in specific digital applications for the pulp & paper industry. These applications address the specific needs of our clients, including, among many others, applications for energy management, optimisation of cogeneration plants, water management, optimisation of wastewater treatment plants, OEE, paper machine data management, etc. These applications, called "engines," are ready to run not only on the AFRY Smart Platform but also on any other platform that the Pulp & Paper mill may have, providing immediate solutions to specific problems faced by clients.

By leveraging our vast industry expertise and digitalisation resources, it is also possible to develop completely new applications as turnkey solutions or through collaborative projects with the client.

Digitalisation is not about an individual project but rather an integral part of daily business activities. AFRY is your long-term partner for paper industry clients on this journey, providing resources and digital solutions, as well as accompanying them on the path of continuous improvement in the exploitation of these solutions.

This article was partly published originally in El Papel -magazine in April 2024.