Turning Vision into Reality: the roadmap to efficient operations by mastering improvement projects

Effective and efficient operations do the right thing in the best way. By definition, they are profitable.

Written by Jakob Redlinger-Pohn and Stefan Kucher

Effective operations can be characterised by running machines, not running people, with the goods in a well-managed flow along the value chain – from raw materials to production and shipping of finished goods. The bottom line is that variable costs are reduced, and fixed costs are used to add value and improve operations. Controlled and managed improvement, based on an understanding of the root causes behind it, trumps firefighting any day.

Efficient operations are characterised by collaboration that ensures the flow of information and gets all departments working towards the same goal

This statement is easy to sign. Unfortunately, it is all too often not the practice. Divergent individual and departmental goals and objectives, together with missing links between departments, create misalignment and result in loss of efficiency.

Consider sales, production planning and production itself, with their individual goals of maximising orders and keeping operations in defined cycles to minimise changeover losses. It is easy to see that too much focus on one will reduce the other. An example is a quick order, a profit won by sales. Planning manages to add the order to the current production. Changeover time and material losses are incurred, and in the worst case, upstream preparation of intermediates and work-in-progress is thrown out of tact. It is not a question of forbidding the take-in of additional sales and only allowing production in large cycles by ignoring the additional profit from sales. The point is to make extra profit while producing profitably. This requires a proper flow of information between the departments, enabled by the management system.

Uptime is another example that can suffer from a lack of communication between the departments. Maintenance works to keep the machines running but is unaware of what is happening in operations unless communication structures are in place to create awareness of each other's contribution. Companies and business structures evolve over years and decades and can reinforce unhealthy practices. However, none of this is set in stone, and legacy processes can be changed for the better.

The common goal of all employees is the profitability of the business, but not all employees can or should be tracked by this target. The trick is to set and align area-specific individual and departmental goals and make them tangible, understandable and in support of the tasks that need to be performed (read more in our KPI article). High-performing operations do an excellent job of making their people accountable and responsible for their contribution to the common goals by making them understand the impact and direct influence of their related tasks at the right level of granularity. Their DNA is sketched in Figure 1.

- The business and operational strategy is represented in defined objectives. Key Success Factors (KSFs) that build towards the objectives are identified

- Key Performance Indicators (KPIs) are derived from the KSFs. The KPIs are specific, and cross-dependencies are considered. Pitfalls, such as management KPIs assigned to operators, are avoided

- Conflicting KPIs are avoided by breaking down silos and ensuring communication. All employees work towards the common goal

- KPIs are visualised and provide timely information, enabling early problem resolution. That is part of the quality built within the management system. Rework is reduced, and reliability is increased

- Digital tools are used to improve the speed and quality of information flow, enabling variable cost optimisation and additional production throughout the entire mill

- It is understood that digital tools are not a substitute for a proper management structure but a support. Digital tools improve the productivity of well-structured operations but can cause profitability losses when these are lacking

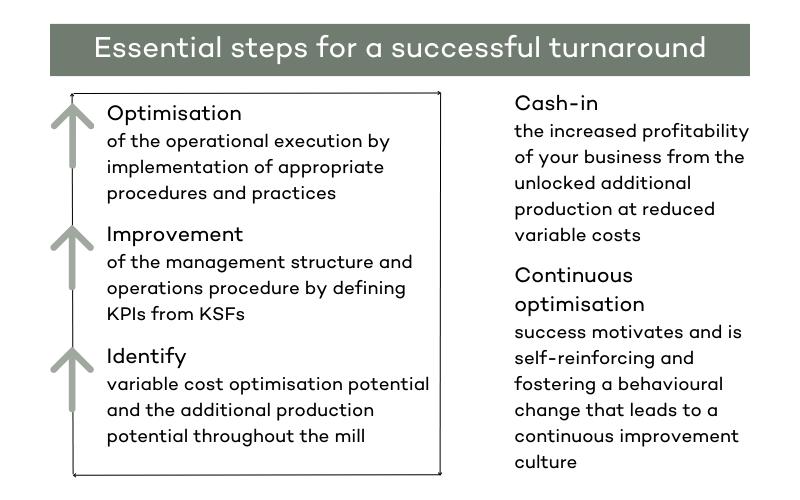

Turning around underperforming and inefficient operations follows a systematic approach, summarised in Figure 2. The aim is to (i) identify and analyse the Execution Gaps measured in monetary terms, (ii) define the focused improvement steps, and (iii) capture the improvement potential by introducing new practices that your people internalise.

The return on a successful turnaround project can be significant. For example, in the bio-based industries, we have found an additional profit of €12 to €65 per tonne produced, based on average values prior to recent business disruptions (read more about their impact here). The profitability potential of a successful turnaround is only increasing as energy and logistic costs rise.

Having the right team is crucial to success. For this purpose, a mix of skilled team members with process and change management experience is needed to ensure that the change process is well-supported, highly accepted and not stopped halfway through. An external partner can accelerate your success and reduce the cost and duration of your operation transformation process. What they should bring into your support is a mix of proven methodologies.

Partner with AFRY to transform your operations

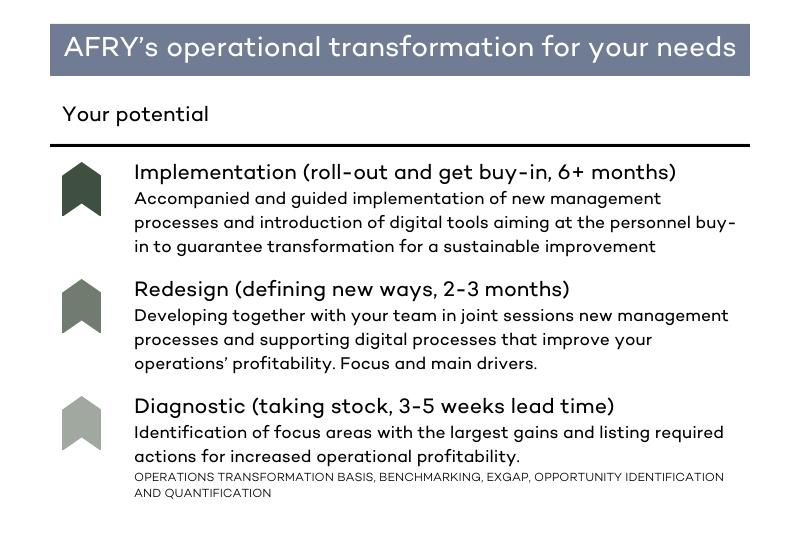

Trusting the right partner to support your operational and organisational transformation is, as the saying goes, half the journey. We earn our clients’ trust by bringing together a multi-disciplinary team of business consultants, change managers and engineers who understand your unique operations and business. Using a step-by-step approach based on a proven continuous improvement process framework, we work with you to identify the areas of greatest benefit and transform them for higher profitability (Figure 3).

The starting point is a thorough diagnosis of your operational and business performance, identifying where to focus, what to target, and how to act. This is followed by the redesign of your management processes and supporting digital tools. We focus on the areas that will deliver the greatest benefits. Crucially, we do this without disrupting your production.

What sets us apart is that we do not walk away after creating a list of actions. Instead, we engage at all levels, starting on the shop floor, to guide and support you through the implementation phase. Our aim is to get your people to adopt the new processes and use the new digital and management tools. Essential to our understanding of project success is that the new ways of working together are not lost during the transformation. This ensures that Execution Gaps are closed, and operations are transformed for higher profitability.

We are proud to have helped our clients to close 92.9% of the Operational Execution Gaps identified in the diagnostic after a successful implementation. This represents a significant improvement in margins, as well as a reduction in costs and emissions per unit produced.

Evaluate your potential to reduce variable costs, increase labour potential, reduce emissions and succeed in your digital transformation by contacting us.