Using mountain water to link local resources with circular fishing industry

Fully circular, energy-efficient, land-based fish farm

Railway tunnels have the potential to be very useful to land-based fish farming facilities around the world. Together with AFRY, the Swiss company Basis 57 has made use of tempered mountain water from a railway tunnel to build a fully circular, energy-efficient, land-based fish farm with minimal impact on the local environment.

According to the Global Seafood Alliance, the world’s population is expected to grow to almost 10 billion and food demand will more than double by 2050. Aquaculture is one of the fastest growing industries globally, and presents a resource-efficient alternative, with lower CO2 emissions in comparison to other farmed proteins. At the same time, the fishing industry is facing major environmental challenges such as bio-diversity loss due to overfishing of lakes, rivers, and oceans. In search of new sustainable methods and technologies, land-based fish farming presents opportunities to meet the challenges of rising demand and environmental issues.

We want to decrease overfishing in Switzerland and Europe by building a more local and sustainable fish farm.

- Thomas Gisler, CEO of Basis 57

Land-based vs. open sea

Farming seafood is typically done in the open sea, in lakes or on land. In contrast to open sea aquaculture in underwater nets, however, Recirculating Aquaculture Systems (RAS) land-based fish farming minimises environmental effects: less pollution, water is saved, fish waste is eliminated, and there is no use of antibiotics or dangerous chemicals.

The company ‘Basis 57 nachhaltige Wassernutzung AG’, which means ‘Basis 57, sustainable water usage corporation’, (“Basis 57”) has identified a unique opportunity to make use of tempered mountain water for land-based fish farming, in response to the growing need for sustainable fish production and consumption. AFRY’s long-standing expertise within land-based fishing industry made it a natural choice to handle project management and steering, architectural and construction design, as well as technical coordination in the building of an industrial plant.

The synergies that make more sustainable fishery

The Gotthard base tunnel is located in the Swiss alps and with its 57 kilometers, it is the longest railway tunnel in the world.

During the drilling and construction of the tunnel, the tunnel constructors came across large quantities of warm drainage water from inside the mountain, that had to be managed in order to finish the tunnel construction. This untreated water became a vital source for a sustainable fish farming facility – a natural resource spot for local land-based fisheries.

“When the tunnel constructors drained the water directly into a nearby river, an idea arose to use the mountain water sustainably. Basis 57 had a few suggestions on how we could use the water and decided to create a land-based fish farm”, says Claudio Ferro, Business Development Manager and Head of Project Management Switzerland at AFRY.

In close agreement with local authorities and the railway company, Basis 57 wanted to exploit the resource in the tunnel in a sustainable manner. In collaboration with biologists, and specialists in animal farming and water management, the company combined expertise and local engagement to examine the potential of native fish breeding.

“The project was born in a small canton in Switzerland with many experts and locals sharing their ideas, procuring funds, and contacting small investors. This showed how local citizens can join forces to make something special together – for the sake of the environment”, says Claudio Ferro.

Mountain water becomes a natural power source

Traditional fish farming facilities require high amounts of energy as well as transportation between different farms over the fish’s lifetime, which generate emissions. With high-quality mountain water, Basis 57 found a way to connect the facility to the natural resource. The water is not only very clean and fish-friendly but is ideally tempered at 13-15°C. Consequently, the mountain water becomes a natural power source in the production, minimising the need for water heating and energy waste, leading to less emissions.

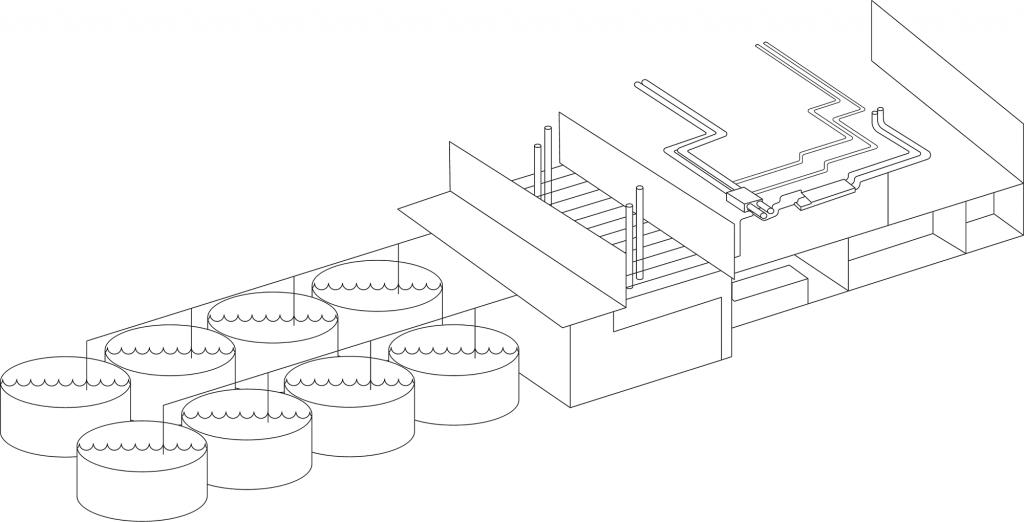

The facility is based on a recirculation system that sustainably reproduces the full product-cycle of farmed fish, from hatching to adulthood to finished packaged fillets. The facility consists of several indoor recyclable water tanks, which are used during the different phases of breeding production, creating the right aquaculture environment. The plant uses the mountain water, which is recycled and treated before it is returned to the river. By using mountain water, nearly 100% of the water gets reused and cleaned from harmful chemicals. All waste products from the fish production can also be reused to produce by-products such as biofuels or animal feed.

The livestock sector plays a vital role in the transition towards a sustainable society. Increasing incomes, changing diets, and population growth have made the livestock sector one of the fastest growing agricultural sub-sectors in middle- and low-income countries. Globally, livestock contributes up to 40% of the total agricultural activity. 1

The fish that meets the local requirements wins

Generally, selection of fish species is mainly based on market demands, and the breeding environment needs to be tailored to the species’ special requirements. The well-known pikeperch was therefore a good match, especially since no suppliers in Europe have been able to deliver pikeperch in constant growth conditions. Basis 57 wanted to exploit this advantage on the market and breed the fish in a sustainable way. RAS land-based fish farm facilities require very specific sets of circumstances to be able to breed delicate species. Pikeperch is highly sensitive, so it requires carefully monitored production, system management, and technical stability. The building design and construction is also strictly integrated into the local environment since it is very important to preserve the natural landscape in Switzerland.

"Building this type of plant comes with several challenges. The fish are very delicate and require darkness, special fish feed as well as calm and clean water at a very specific temperature. You can very easily end up with mass mortality of fish, says Gianluca Punzi", Architect at AFRY.

In 2021 the production facility was set in operation, producing 180 tonnes of pikeperch per year in the first phase. The plan is to expand the production capacity of 540 tonnes per year.

"In Switzerland, sustainability is a big trend, yet sustainable consumption comes with a price tag. We need to think carefully about the trade-off between the economy of scale approach and quality.", says Thomas Gisler.

The principle is to choose a particular fish species and adapt your business plan according to the local availability of resources. That’s how to make a sustainable product.

- Claudio Ferro, Business Development Manager and Head of Project Management Switzerland at AFRY

Local fish clusters is the model fit for the future

In Switzerland, domestic fish production covers around 6% of the Swiss fish consumption, while 94% is covered by imported fish. Since consumers increasingly expect affordable access to sustainable, healthy, and locally produced food, the sustainability perspective has been the project’s top priority.

“Nowadays, it is not uncommon that fish, especially salmon, is produced in Norway, processed in Poland, and packaged in France before it reaches the consumer. This type of value chain has hugely negative impacts on the environment. With this kind of system, you farm the fish in direct contact with the target market”, explains Claudio Ferro.

The circular economy employs small-scale processes to extend the use of local ecosystems. The Basis 57 project shows how local awareness and small-size production matter. It can serve as a source of inspiration for other food producers, to shape new sustainable fish clusters in their local regions, depending on the environmental conditions and infrastructure. The scalability is therefore very much dependent on new approaches and collaborations, and any expansion of the system requires attention to details and complex solutions.

The whole production chain is managed through several stages, starting with the incubation stage in the fish area. This is where the hatching and breeding of the fish occurs. The incubation stage is followed by the Post Nursery, Pre-Growing and On-Growing departments where the fish grows to the right dimensions. The water is treated in the RAS-systems where the water gets mechanically cleaned, biologically treated, recycled, and depurated. The fish is then transported to the processing area, where they are prepared, packaged, and sent to local food retailers.

Sustainability at AFRY

Footnotes

- 1. Source: The World Bank. (2021). Moving Towards Sustainability: The Livestock Sector and the World Bank. https://www. worldbank.org/en/topic/agriculture/brief/moving-towards-sustainability-the-livestock-sector-and-the-world-bank a↩