AFRY e-DAP

Predictive modelling by means of data analytics

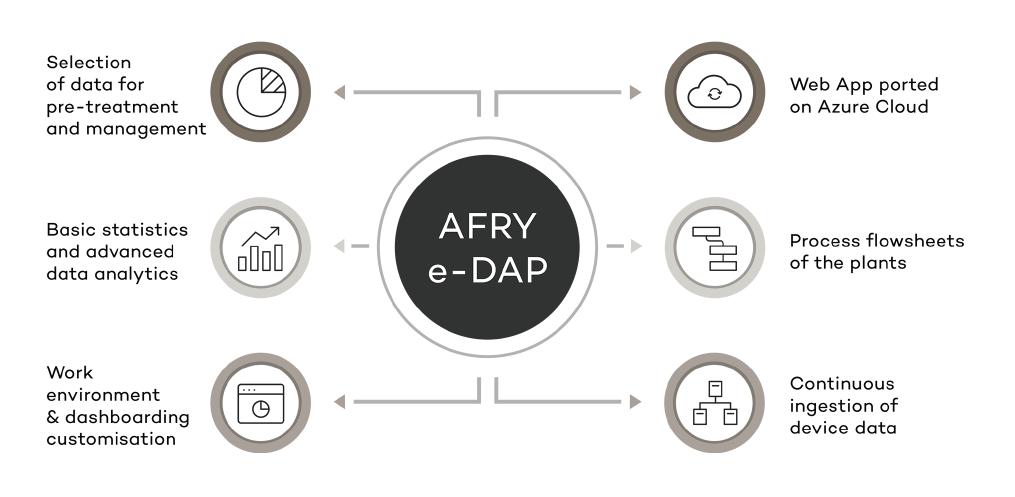

AFRY e-DAP in a nutshell

AFRY e-DAP is an end-to-end cloud-enabled platform, performing Digital Control (DC) and Data Analytics (DA) of plant data across various industries. With its digital control element, the platform enables asset management, comprising data collection and live dashboarding, plant control and file/data sharing. The core components of the data analytics module include:

- data engineering

- predictive modelling using machine learning

- digital twin and insight, where pertinent KPI’s are made available.

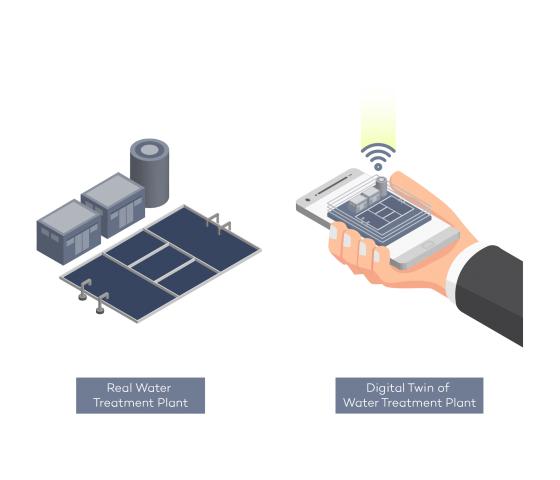

Digital twin web platform using real-time field data

AFRY e-DAP is an end-to-end digital-twin platform aiming at virtually improving operations and maintenance of important elements of equipment and key processes in industrial plants. With its data collection capabilities provided by process instrumentation, coupled with a modern IoT networking and storage, the platform offers a work environment where clients accumulate vast amounts of time-series plant data and infer potential insights into the operation and maintenance using machine learning. AFRY e-DAP can be applied in industry, in services and in infrastructure as a Web App tool supporting:

- Operational (predictive) maintenance

- Production control

- Planning and optimization of processes

- Life cycle management

AFRY’s combined expertise in IoT, Engineering, Simulation and Data Analytics will support you in exploring plant or lab-test data and transform hidden information into assets.

Tailored Data analytics supporting decision making

The virtual data analytics platform helps you to take better informed decisions in an earlier stage, maximise efficiency & reliability to reduce risks and optimize OPEX costs.

AFRY e-DAP is tailored to your needs and simple to use:

- Use AFRY’s own Azure cloud resources to Web App: Use AFRY’s own Azure cloud resources to access your secured projects.

- Create process flowsheets of your plant’s processes: Identify or label the sensors in your plants and control the data transfer to the central platform of AFRY e-DAP.

- Monitor continuous ingestion of real-field data: Receive reliable information due to constant data inflow from sensors interfaced with the on-site Edge IoT Gateway.

- Perform advanced data management: Get support from various tools to select data for pre-treatment, and cleansing including outlier data detection & replacement.

- Conduct basic statistics and advanced machine learning: Tailor output to your needs from basic statistics to advanced data analytics.

- Customise your work environment: Results of the digital twin are presented in a dashboard, and can be interrogated for new operational conditions.

Did you know?

AFRY e-DAP is helping our clients with

- Production control: help you identify hazard management solutions for your operations

- Planning and optimisation of process: leverage AFRY’s expertise to build your own data analytics activity

- Operational (predictive) maintenance: help you to take preventative measures to avoid troubleshooting issues

- Life cycle management: inform you about the efficiency and reliability of the system

Are you ready to discover the potential in your organisation as a tailor-made version, implement it into existing platforms or simply as an add-on feature? Contact our group of experts today to see how AFRY e-DAP can help you.

Air quality in the Gotthard Base Tunnel

Measuring quality of air in the tunnel and predicting long-term impact on the integrity of the tunnel: 57km of tunnel smartly operated and maintained with AFRY e-DAP, our engineering Data Analytics Platform.

AFRY e-DAP supports our client to predict the impact of external weather conditions and allows them to smartly operate the airflow in the tunnel without having to be present: “Tunnel Digital Twin” is used as the engine managing climate conditions in the tunnel.

The platform predicts air temperature and humidity in the tubes based on air velocity, portal temperature and humidity. The dependencies between external and stagnant air conditions in the tubes when the air quality decreases are made transparent on the AFRY e-DAP dashboard.

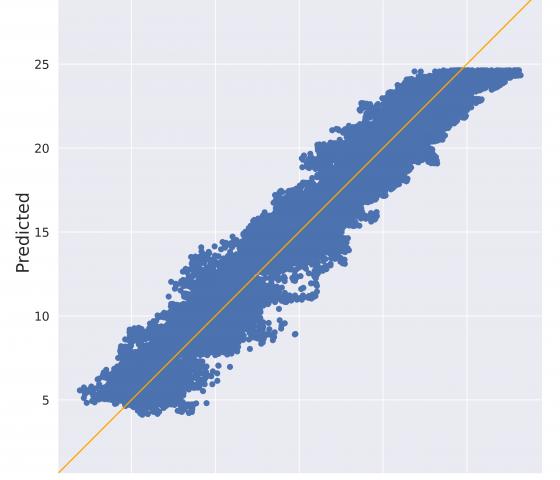

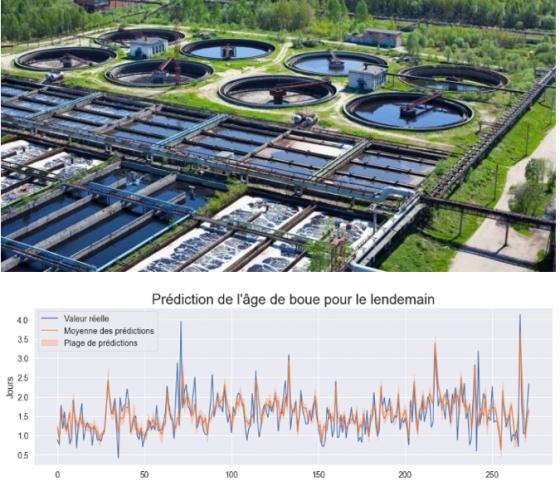

Process modelling in waste water treatment plant

Waste water treatment plants require careful monitoring of operation parameters, including inflows, outflows and a ready-to-apply measures to respond to increased external need, e.g. population growth. From an operational excellence point of view, operators must optimise energy consumption, bio-chemicals, oxygen and nitrogen, etc.

The AFRY e-DAP-based solution consists of a predictive modelling process, comprising the following steps:

- Operation data gathered from devices at Swiss waste water treatment plant Estavayer-le-Lac at a frequency of 5 minutes, over 10 years.

- After thorough data management, we used various machine learning algorithms in order to predict the sludge age in the plant.

Consequences for the plant operator include: Improve and optimise operation, optimise oxygen consumption as a function flowrate, water temperature, acidity, nitrogen levels, and other organic content.

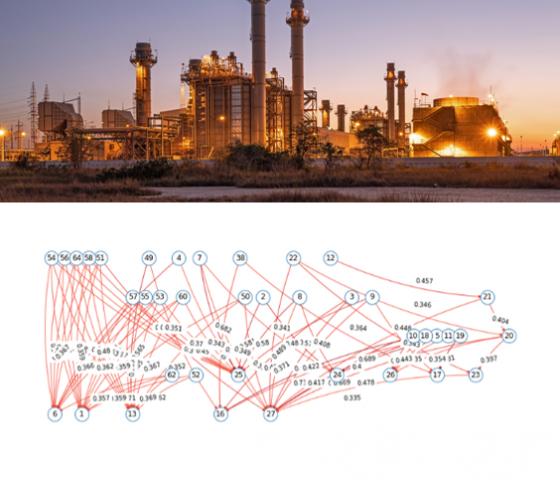

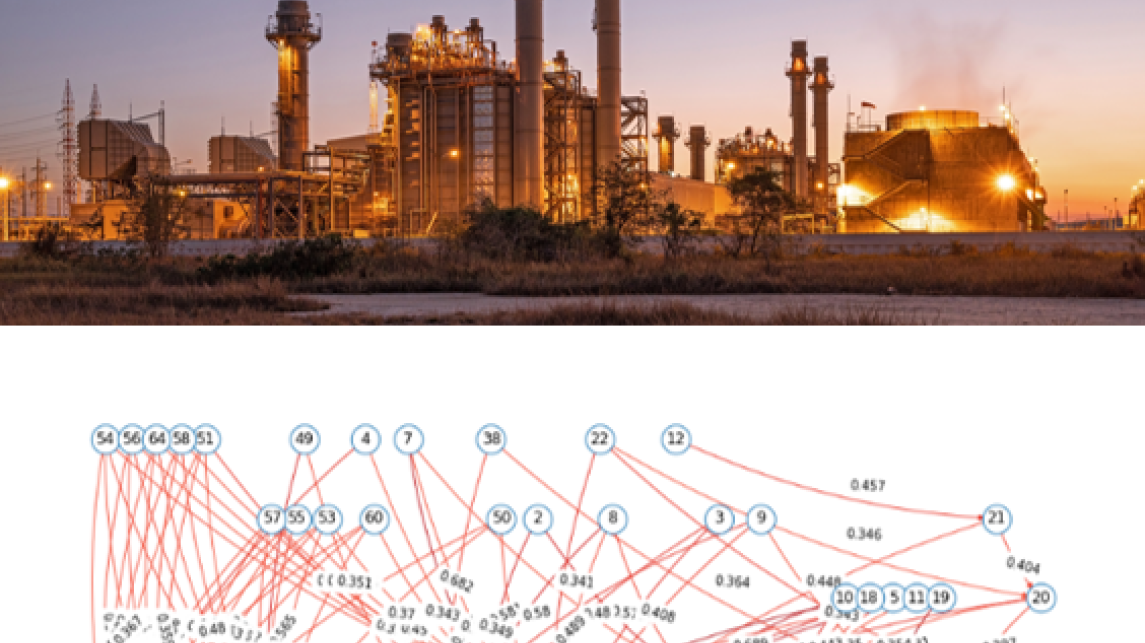

Causality analysis & anomaly detection in energy power plants

Among the various issues met in energy production plants, operational anomaly is one of the trickiest: the system behaves normally before exhibiting unusual instabilities caused by hidden anomalies that are difficult to identify. Production can be stopped for long periods of time, causing losses, especially when safety measures are involved.

With AFRY e-DAP, our experts added a model dedicated to anomaly detection via causality analysis, where the dependence of every variable is meticulously assessed using a powerful in-house Causality Analysis tool. This applies to energy power plants as well as chemical & process plants.

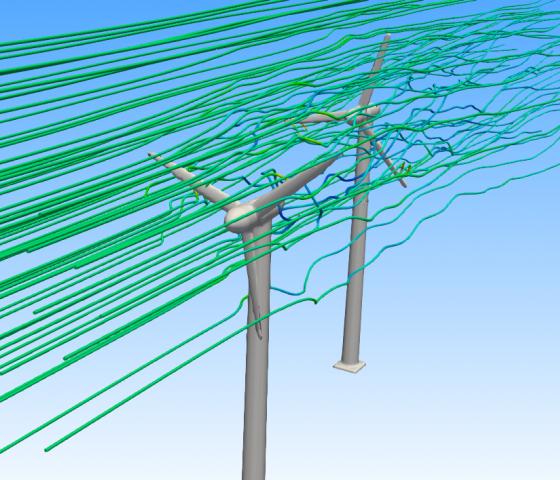

Simulation Digital Twinning (SDT)

Computer-Aided Engineering (CAE) has supported the industry in its transition from trial-and-error towards physics-based modelling, but our ways of handling and getting value from simulation results have changed little during this period. Indeed, the business model of CAE centers almost exclusively around delivering base-case simulation results with a few additional operational conditions.

AFRY’s new solution consists of a new paradigm for the exploitation of computational physics data, using machine learning to enlarge the simulation databases in order to cover a wider spectrum of operational conditions and provide quick response directly on field. The resulting product from this hybrid physics-informed and data-driven modelling is referred to as Simulation Digital Twin (SDT). While the paradigm can be equally used in different CAE applications, AFRY's experts implemented it in the context of Computational Fluid Dynamics (CFD).

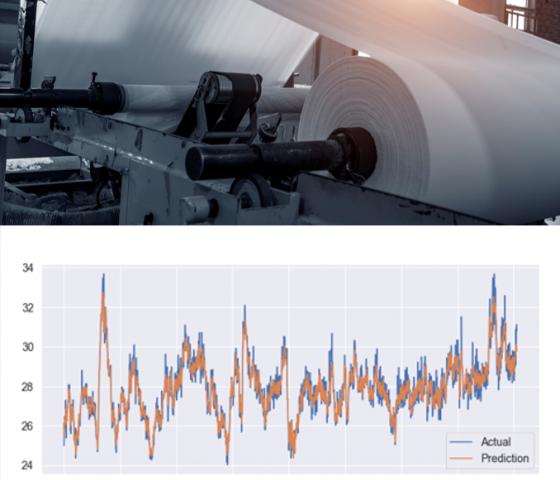

Optimisation of the cooking process in the pulp digester

The challenge among the daily issues encountered by pulp digestor operators:

- Separation swing caused by a production change causes disturbances; stable conditions take a long to be recovered

- Long-time delays make it difficult for operators and automatic controls to compensate for the changes

- Risk of plugging at screening, consumption of chemicals, effluent treatment and off-spec pulp quality

Our solution using AFRY e-DAP is to provide a predictive modelling process, comprising the following steps:

- Feed, production and operation data gathered from plant devices at 5 minute intervals

- After thorough data cleansing and system identification, the quality of pulp sustainability can be modelled

This has the following effects: Possibility to maintain higher separation for increased yield, and reduction in chemical costs & decreased COD load to effluent treatment.

Interested in our offering? Contact us!