AFRY VISI Belt - Conveyor belt condition monitoring system

AFRY VISI Belt provides real time condition information of the conveyor belts and enables to plan right timed maintenance actions

VISI Belt – for conveyor belt condition monitoring

Avoid catastrophic failures and production losses with the help of VISI Belt

VISI Belt Conveyor belt condition monitoring system technology, benefits and modules

- VISI Belt conveyor belt system technology

- VISI Belt System benefits

- VISI Belt Material Side

- VISI Belt Clean Side

- VISI Belt Computing Unit

- VISI Belt Portal

VISI Belt conveyor belt system technology

- Continuously monitor the condition of the conveyor belt

- Two monitoring modules: One on the material side and the other on the clean side of the belt.

- Provides real-time information and reports about the health of crucial conveyor belts

- Provides information about the optimal maintenance window to maintain, fix or change each conveyor belt

- Detects belt wear and tear, misalignment, slowly progressing damages, edge rips, holes

- Alarms when the probability of failure is increasing

- Stops the conveyor belts in severe damages

- Informs the operator of the stoppage reason

VISI Belt increases the conveyors' reliability and optimises conveyor belts lifetime

VISI Belt System benefits

- Increase safety: Prevent unnecessary people exposure from dangerous areas near the conveyors

- Increase production: Avoid unplanned downtime of conveyor belts

- Speed up: Time for troubleshooting

- Save costs: Reduce maintenance costs, energy consumption

- Avoid: Informs about potential failures to ruptures, rips, holes, excessive belt wear, fire and other damage to the conveyor

- Reduce: Falling material from belt, sound emission

- Optimise: Increase belt reliability and optimise lifetime

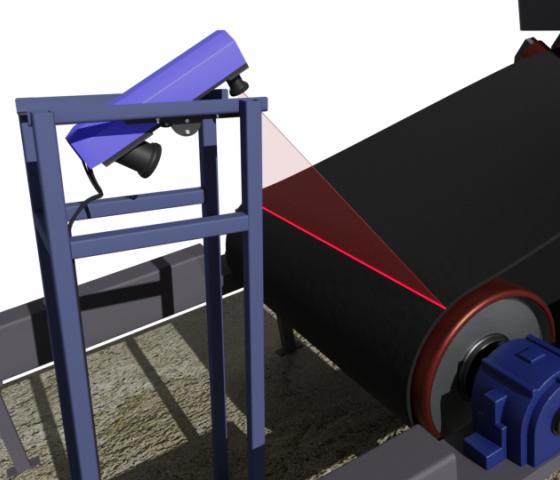

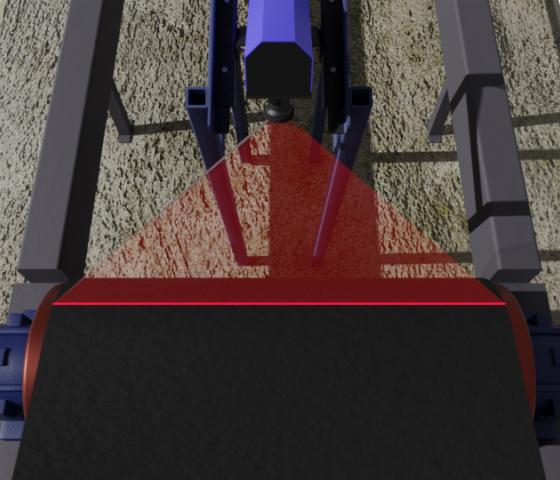

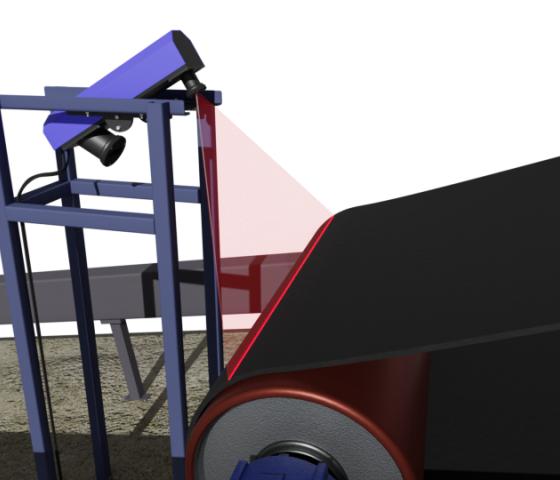

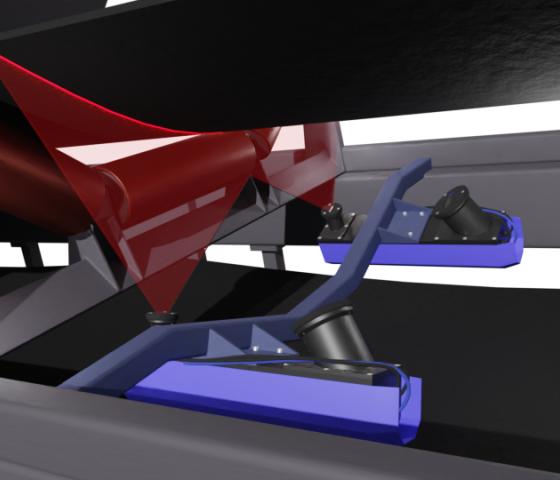

VISI Belt Material Side

VISI Belt MS monitoring module – for monitoring the material side of the belt

The MS monitoring module analyses the cross-directional profile of the belt based on real-time optical 3D surface scanning. It detects belt thickness, wear, misalignment, edge wear, rips, holes, defects, damages and unwanted objects.

Straight measuring Beam. Installed close to the head- or tail pulley or in another stable position.

- Creates defect map for the entire length of the belt and makes a detailed fault analysis. Faults are classified according to the severity of the fault.

- Can be connect to the customer´s control system for fault information data.

- Sends the defect map to cloud/customer servers for advanced analysis and visualisation.

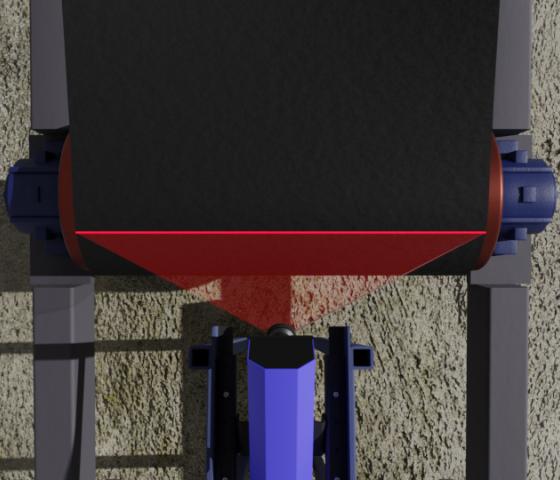

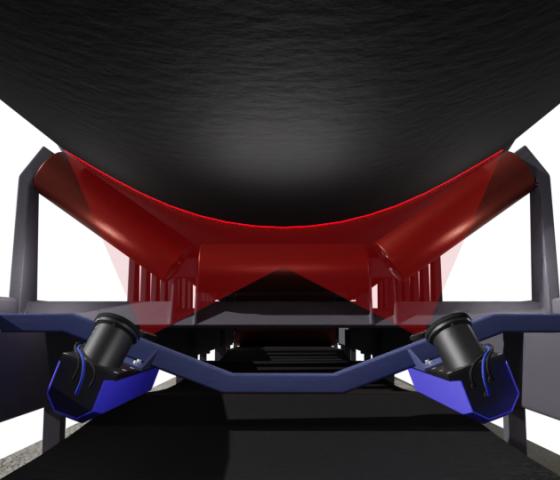

VISI Belt Clean Side

VISI Belt CS (Clean Side)

VISI Belt CS is designed for the conveyor belt clean side condition monitoring.

- Detects with 3D surface scanning the damages that pierce the conveyor belt and detects holes, rips and objects that have penetrated the belt

- Stops the damaged belt by sending a signal to the control system.

- Curved measuring beam. Installed on the bottom of the top belt between conveyors frames immediately after the feed chute

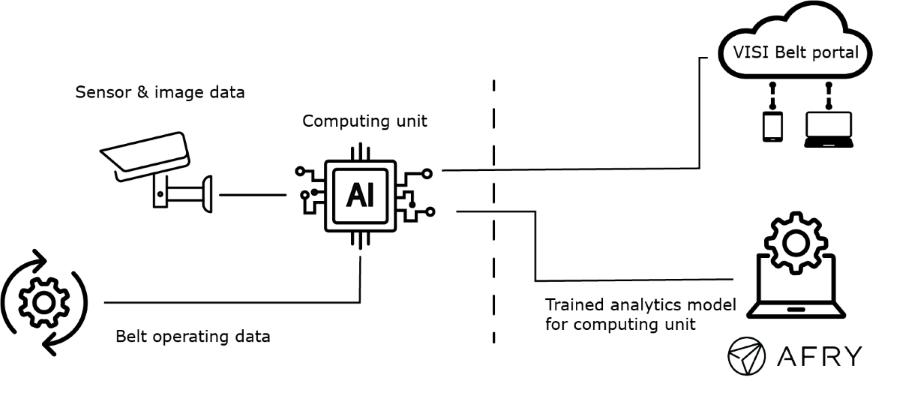

VISI Belt Computing Unit

VISI Belt CU (Computing Unit)

- Computing unit on site or Virtual Machine at customer premises depending on selection

- Analyses the profile of the belt surface

- Real-Time fault detection

- Alarming and stop signal to the automation system

- Data buffering and transfer data to the VISI Belt portal

Computing unit functions

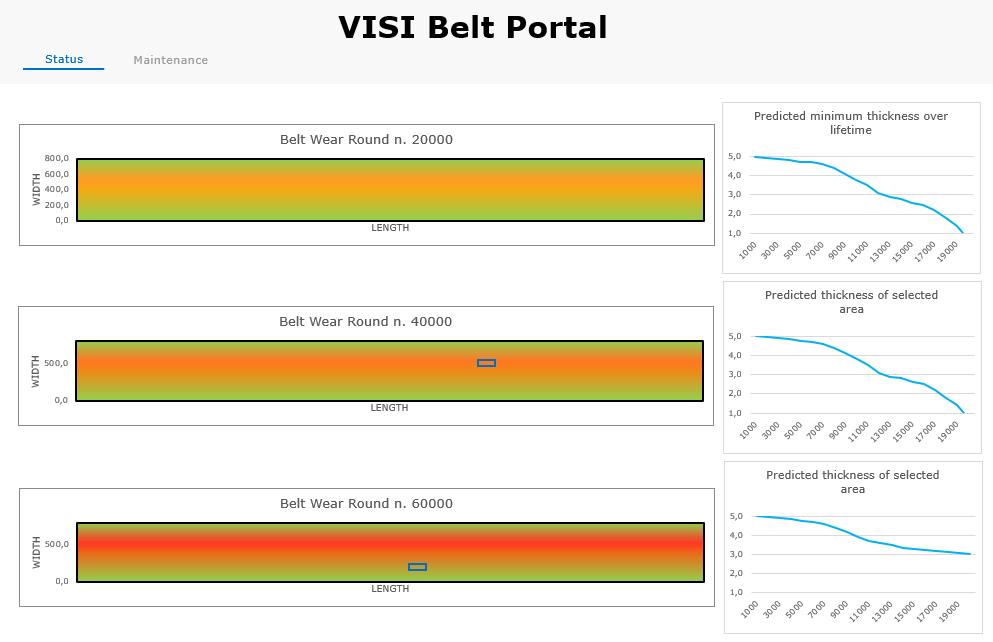

VISI Belt Portal

VISI Belt Portal

Will be customised according to customer needs

- Information about one or several belts

- Belt profile analytics

- Human-labelled fault classifier data

- Alarms /events

- Data logging

- Trending

- Belt lifetime prediction

- Visualisation, dashboard

Data visualisation

- A visual view of the belt´s health trend based on the picture and profile measurement data

- The trend of the belt thickness (wear) visualised on the full belt area

Predictive analytics

- A forecast of belt wear in selected areas based on usage measuring statistics

- Forecast of remaining lifetime

- Recommendation of the optimal time to fix or change the belt