Circular economy in mining and metals

Improving material efficiency and going circular in mining and metals

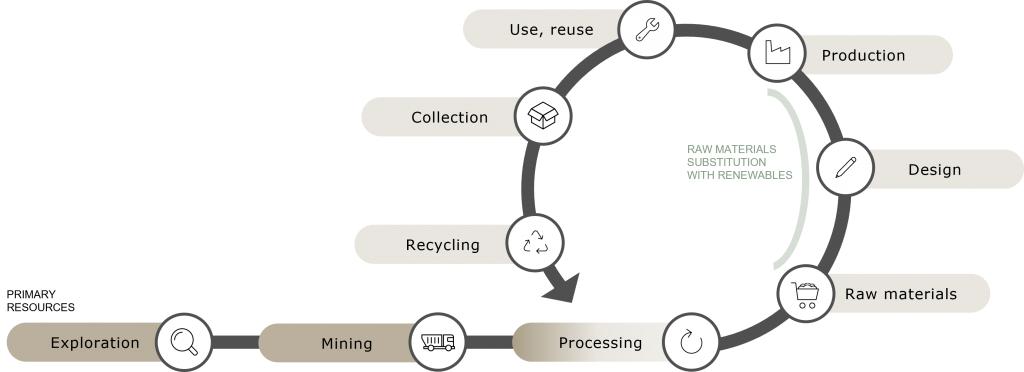

Circular economy restructures entire value chains, as waste is designed out and products are not discarded, but looped back into the material flows. Across industries circularity is an engine for new opportunities through disruptive new business models as the concept of waste is transforming to that of value.

A transition to more circular material flows in mining and metals needs to take place. The mining and metals industry has several opportunities to increase resource efficiency. For instance, the full potential of waste as raw material has not yet been realised.

Mine waste typically includes rocks, sludge, tailings, wastewater and other by-products, depending on the type of mining method, type of ore, the geological set-up and processing techniques. The goal is to valorise what is today to a large extent still seen as waste into resources that can be further utilised in the process or in new end-uses and products. Not only is this a way to improve efficient use of natural resources, but a way to improve the overall performance of the mining sector.

Towards higher material efficiency

AFRY is committed to identifying and developing technological solutions that result in more effective recycling operations, waste reduction and elimination, and repurposing waste streams into new products.

Higher material efficiency and the development of new end-uses for by-products, as well as striving for zero-waste and improving the recyclability of raw materials and by-products, are critical to the shift to circular economy solutions. With the traditional boundaries of industries blurring, circular economy also fuels new business models and partnerships for the industry.

Offering a wide scope of services for minerals and metals recycling

AFRY's diverse set of abilities and expertise make us a reliable partner throughout your project's development. Whether your process is hydrometallurgical or pyrometallurgical, we have technical professionals with extensive industry expertise. We can assist clients through the full process development cycle, from pilot testing through to technology selection and detail engineering, as well as start-up and commissioning services during the project implementation phase.

Recycling cuts the carbon footprint of products

Recycling enables the creation of new goods with a far smaller carbon footprint than by extracting virgin resources; therefore, it is vital to change present practices. Metals are circular by nature, and can be recycled indefinitely without losing their properties.

Our experience in recycling projects on an industrial scale spans more than 45 years. To support our clients even better in circular solutions, we are committed to continuously improving our expertise in recycling processes. For example, AFRY’s cross-sector expertise throughout the whole battery manufacturing value chain – from ore mining to battery cells and modules, and all the way to battery reuse and recycling – enables us to assist clients at all stages of their operations. Recycling of battery materials will not only cut the demand of primary resources and waste generation, but it will also drive down the battery costs.

The EU aims to recycle 70% of the mass battery waste by the end of the decade and is working on a new regulatory framework for batteries. The proposed changes would for example place an recycled content declaration requirement, which would apply from 1 January 2027 to industrial batteries, EV batteries and automotive batteries containing cobalt, lead, lithium or nickel in active materials.

Meeting the outlined recycling targets will require a totally new way of thinking about all recycling flows, as well as significant technological advancements in order to achieve a clear route to large-scale, cost-effective recycling.

Design plays a central part of circularity

The question of what happens next needs to be solved already in the initial design phase. In the case of physical products or even in large scale construction projects, the equation of how different materials are combined and how easily they can be reused, repaired, refurbished, or disassembled is critical and needs to solved at the design stage.

Meeting the outlined recycling targets will require a totally new way of thinking about all recycling flows, as well as significant technological advancements in order to achieve a clear route to large-scale, cost-effective recycling. These material stockpiles in use will be the urban mines of the future.

The fact however remains, that even if we were able to recycle 100% of the minerals and metals extracted, this would not be sufficient to fulfill future material need, and mining for virgin raw materials continues to be necessary to meet society's expanding demand.

AFRY is committed to sustainable mining, minerals processing and metals production

Sustainable mining promotes resource efficiency, minimising waste, and embracing recycling and circular solutions.

As engineers and consultants, AFRY can take an active part in accelerating the pace of change towards sustainable mining and metals. Understanding the interlinkage between process design and environmental performance is at our core.

Our key competencies for circular metals and minerals:

- Mineral resources and reserves

- Mining and metallurgical feasibility studies AACE Class 1-5

- Health, safety and environmental studies, permitting and EIA support

- Multi-disciplinary engineering services

- EPCM (engineering, procurement, project and construction management) services

- Project management services

- Strategical and technical consulting, Management consulting services, including technical due diligence studies and process optimisations

Interested in our offering? Contact us!