AFRY ProTAK

Market leading solutions for production optimization and OEE

1. What is AFRY ProTAK?

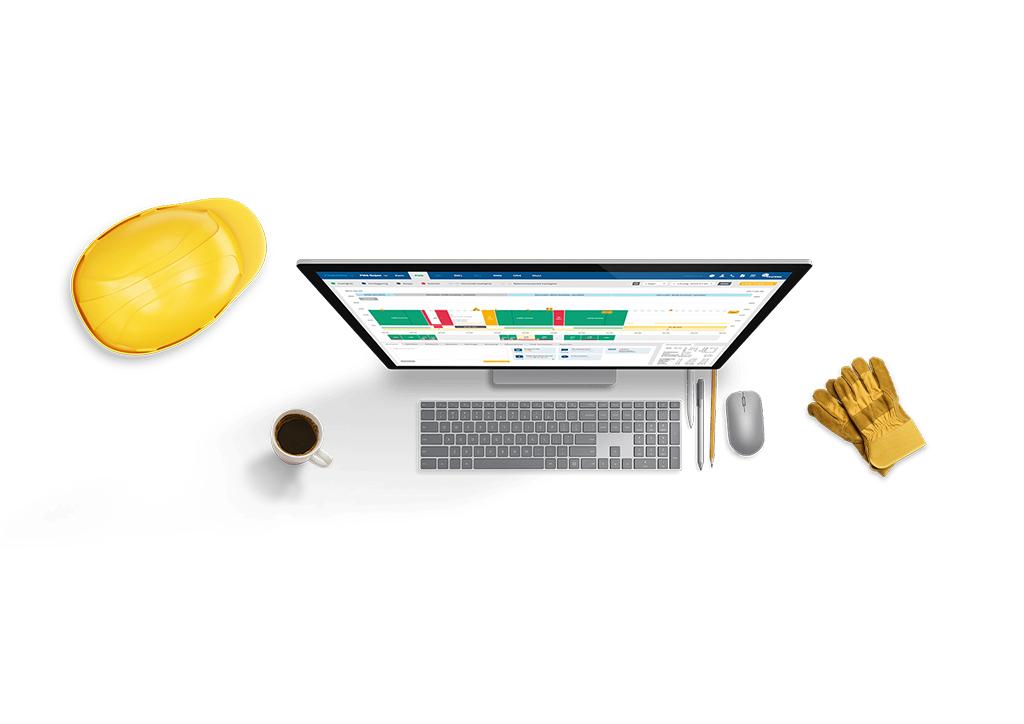

AFRY ProTAK is a product that measures the effectiveness of a plant’s machines*. By doing this you can easily analyze and optimize the production process.

AFRY ProTAK connects the relevant systems and presents a smart view that all users – from site manager to operator – have access to and can easily understand. The product also supports a number of process activities: for example – Patrol monitoring, Journal management and Interruption-camera links. ProTAK is a web-based software offered as a subscription (upgrades are included). ProTAK has the following key functionalities:

- TAK (OEE)-module

- Incident reports

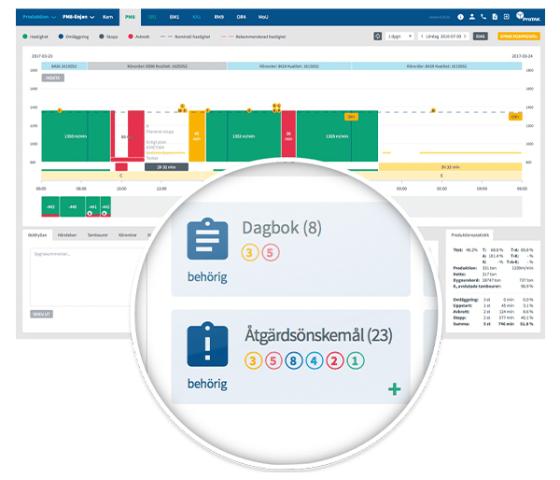

- Journal/notes

- Action requests

- Message function

- Link handling

- Report function

*Our customers are mainly within the process industry

2. What makes AFRY ProTAK unique?

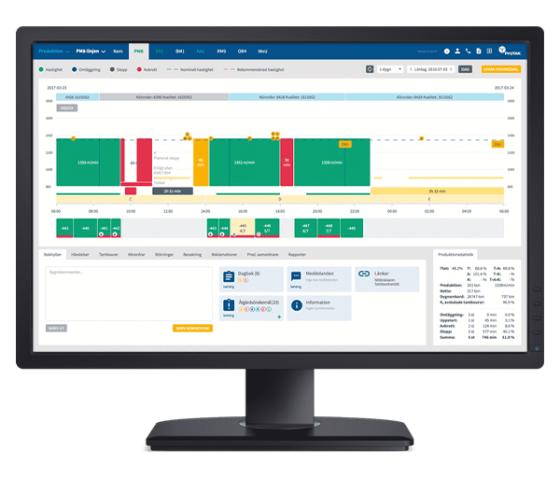

The visual interface, i.e. the graphical rendering of the effectiveness and the inbounded parts, makes is easy for all involved to understand and proactively work with it. Our goal is that you, at any time, can get an instant overview.

It is often in the losses, where the potential for improvement lies. ProTAK’s strength is that it can visualize the losses, and where the losses occur, in a clear way. We, behind ProTAK, have worked in the process industry on all positons – directly with this important question. Our platform is the result of many decades of practical experience, working with process optimization.

3. How can AFRY ProTAK support you?

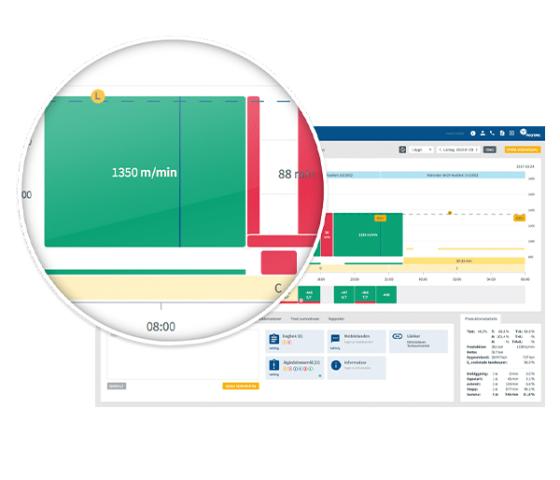

All the information that is recorded and fed into AFRY ProTAK, is visualized in a clean-cut logical picture.

To be able to clearly see how the machines, or the whole department section, use its capacity – is an important element for understanding the process, it also triggers the users to act.

Find everything in one view

AFRY ProTAK has a clear, predefined view for each department and machine. Together with the open interface, you are able to see the other department's “upstreams” or “downstream”. This gives you a better understanding of the factory process.

Although, ProTAK has standardized views: there is of course room for plant-specific accommodations.

Both overall and details

AFRY ProTAK gives you a great overview of a department's total effectiveness and its usage of resources. ProTAK also gives you the detailed information. The users can find everything from, how requested maintenance measures are checked off, to operators´ notes.

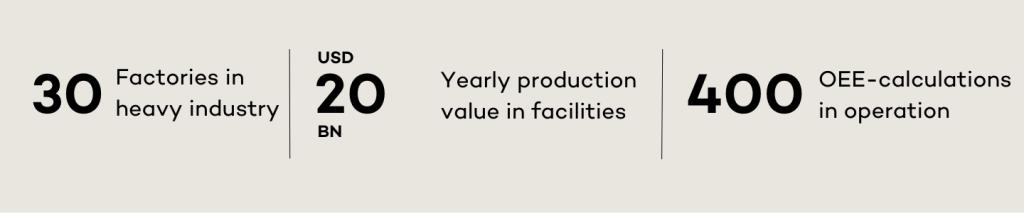

We know, through the hundreds of OEE-calculations we have made, that AFRY ProTAK substantially contributes to the effectiveness of a plant's machines. Furthermore, it gives the factory and the employees a common goal to strive for.

Per Gannå, Founder of AFRY ProTAK

References:

4. AFRY ProTAK Highlights

-

OEE

AFRY ProTAK is built upon a deep understanding of machine effectiveness, or OEE as the standard measurement term is called.

-

SUPPORT

All our customers have a personal contact person from our support team, who is pleased to serve you immediately. Our support is vital to us, we see it as an opportunity to develop our product.

-

REAL-TIME UPDATES

AFRY ProTAK collects data from underlying systems in real-time. Accordingly, you will have the best prerequisites for making the right decisions and working proactively.

-

SIMPLICITY

The graphical interface reduces education costs drastically. The platform is intuitive and direct. Simplicity brings understanding, and the latter makes us act.

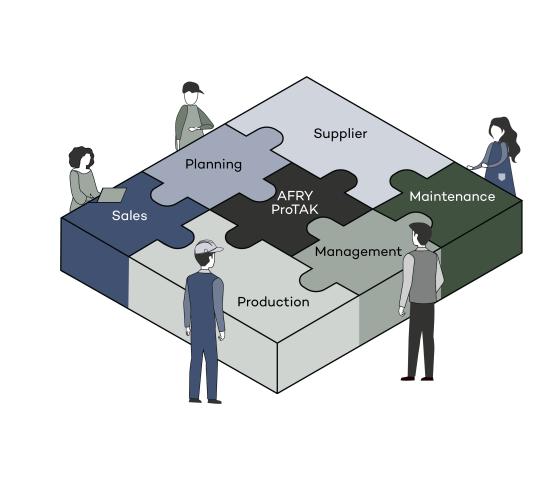

5. Technically, how does AFRY ProTAK work?

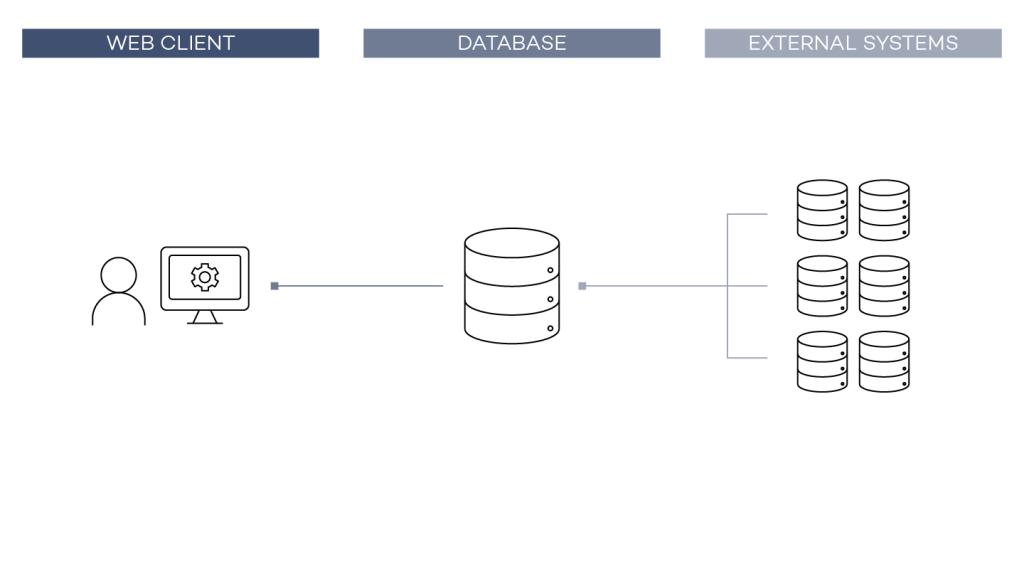

In order to calculate the OEE-value, data is needed from different systems; for example, the business and machine systems. In ProTAK, we bring this information together and generate a visualization in one common picture.

We collect the data from all the relevant systems. For example roll handling system, camera system, plant register, purchase, and warehouse system. The information from these systems is collected together in our ProTAK database. This happens in real-time.

Through an ordinary web browser, you can as a user, get access to the data in the database. It is visualized in intuitive graphs and time axes.

What is OEE, and how does it connect to AFRY ProTAK?

OEE stands for ”Overall Equipment Effectiveness”. In Swedish, we use the abbreviations TAK.

OEE calculations are used for creating data, information, and statistics that can be used for optimizing production flows. This is how we usually explain OEE

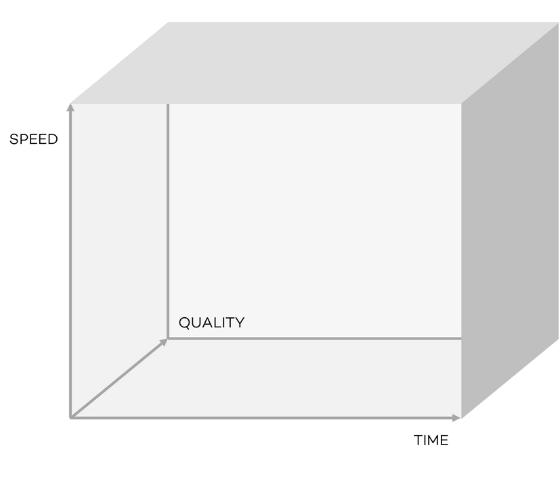

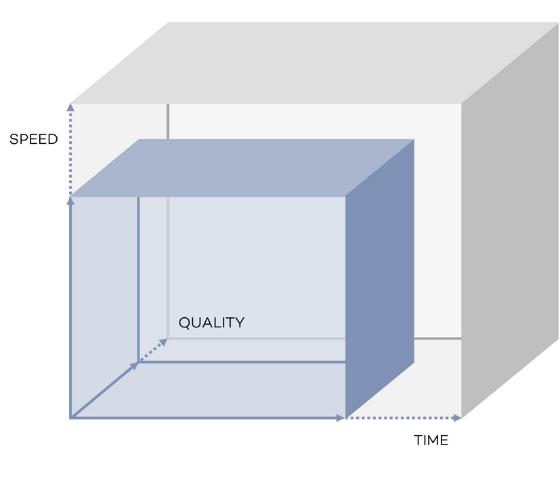

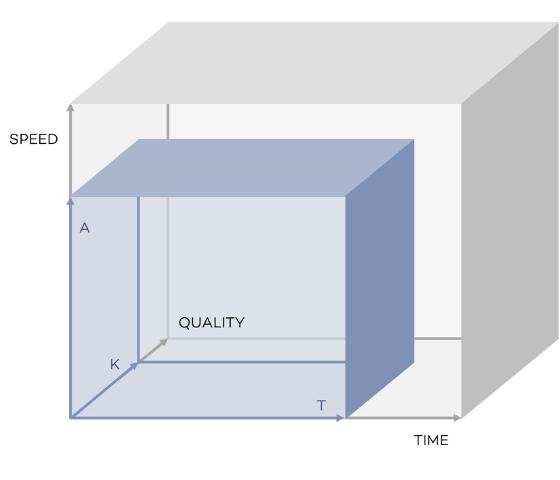

This box represents the theoretical capacity. The parameters are Time = time available, Speed = maximum production speed (per unit) Quality = gross produced, 100% quality approved.

The dotted lines between the two boxes symbolize production events that have caused losses.

It is highly important that these events (losses) are structurally registered in the database. Through the structuring of these events, we can – with a statistical process – get an in-depth insight.

T, S, and Q can simply be regarded as the grey arrow’s length, divided by the blue arrow of the respective axis. Or, T, S, and Q can be described as the volume of the blue box divided by the volume of the grey box.

OEE, is just a measurement of how well a machine, or a process section, is being utilized. The most important element, is that the events of the production (losses) are registered – in order to find bottlenecks and weak sections via statistical processing.

TAK/OEE OCH AFRY ProTAK

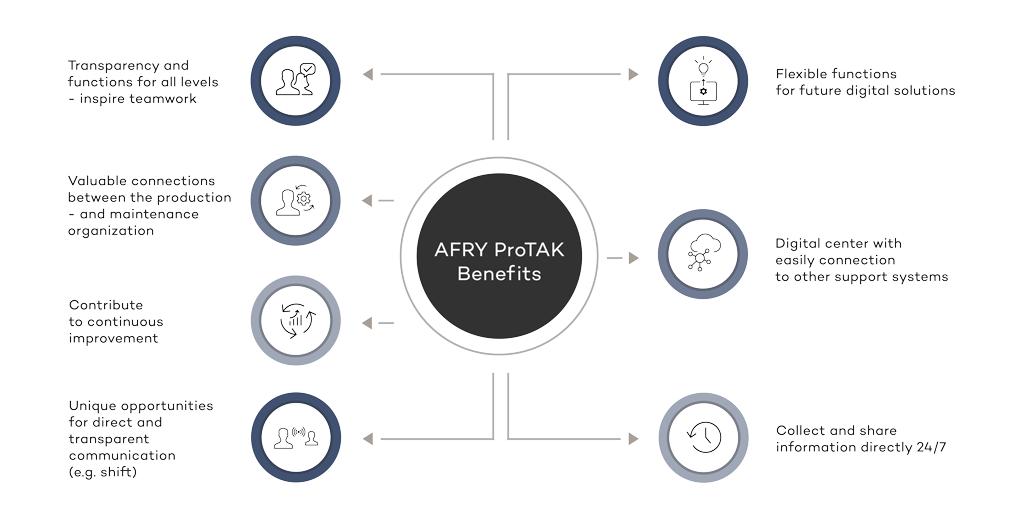

In AFRY ProTAK, we make TAK/OEE measurements and calculations and present it visually on a time axis. Furthermore, we connect other relevant systems (purchase, case, claim, camera system), in order to get a more profound picture of the process at hand. By doing this, the different departments and the factory as a whole can clearly see – in a transparent way – where the losses occur. Consequently, everyone can participate and work proactively in the strive for improvements. Here are some examples, where OEE calculations help us to understand how we can make the right decisions for production

improvements:

- We can provide maintenance-planning.

- We can act quickly, due to the real-time visualization of production.

- We can prioritize operational disturbances.

Support and customization as needed

- When ordering AFRY ProTAK, support is included during normal working hours. Support questions are easily registered via an e-mail address, and a case number is obtained to follow the case. Any problems are resolved according to the "best effort" principle in dialogue with our customers.

- Additional services, such as Customization of reports, Integrations, Configurations, Training, and Consulting for business development, can be ordered via our support or by contacting our sales team.

- We work closely with our customers in an ongoing dialogue in order to constantly develop AFRY ProTAK.

- If you choose AFRY ProTAK, you can be sure that we will be a partner to rely on in your development journey when your business needs change.

AFRY ProTAK

Strandgatan 21

SE-891 18 Örnsköldsvik

Sweden

Tel: +46 10 505 63 11

E-mail: protakinfo@afry.com

Interested in our offering? Contact us!