Automotive Design

Design for a complex future

Automotive design is one of the foundations of our studio. Once our nucleus of User Experience had been created, we realised that our creative and user-centred approach had been long-awaited by our automotive partners.

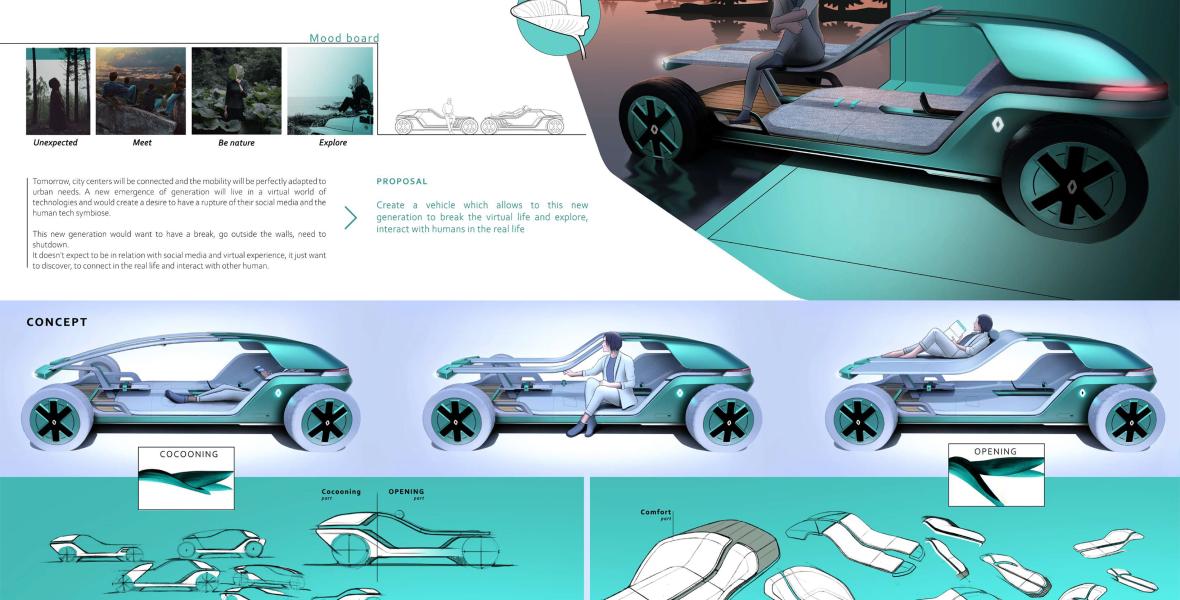

Exterior and Interior, CMF, and HMI are the perfect partners for UX design

In our user-centered ethos, we believe that physical and digital controls should never be considered separate. We also believe that User Experience spreads to every facet of a vehicle through the way an exterior communicates emotion, how the materials feel, and how lighting is designed for more than just surface entertainment. We take care of and excel in Digital Modelling, Physical models & geometry design, CMF, and Design Quality Studio Engineering. Our design teams stretch across platforms and work in every facet of the design to question, improve, and create new ways of answering the needs of our future selves.

Craft in an ever-changing world

As the automotive landscape progresses and our needs for traditional modes of personal transportation change, we are shifting our multi-faceted approach to design.

This, together with our broad knowledge within the Infrastructure, Energy and ICT sectors, put us at the fulcrum of designing the industry shift. We are here to support our clients on the journey of discovery.

Our team has these competencies

- Surface Design

- Studio engineering

- Physical Models and Geometry Engineering

- Design Quality

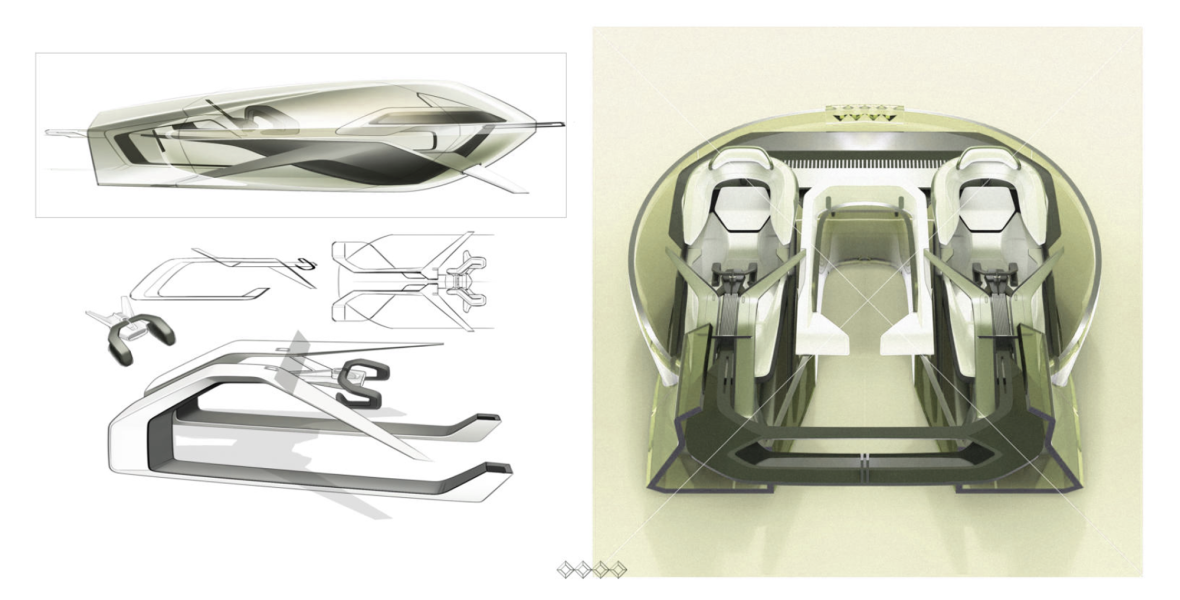

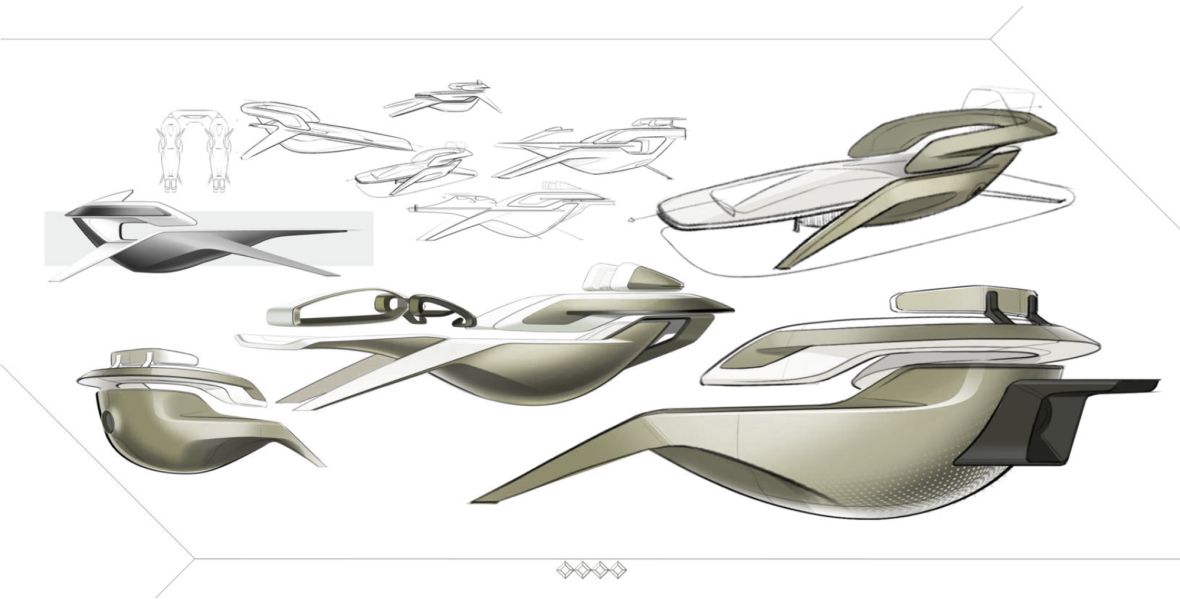

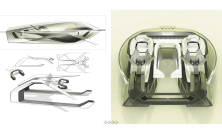

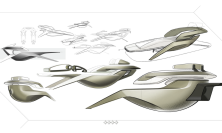

Surface Design

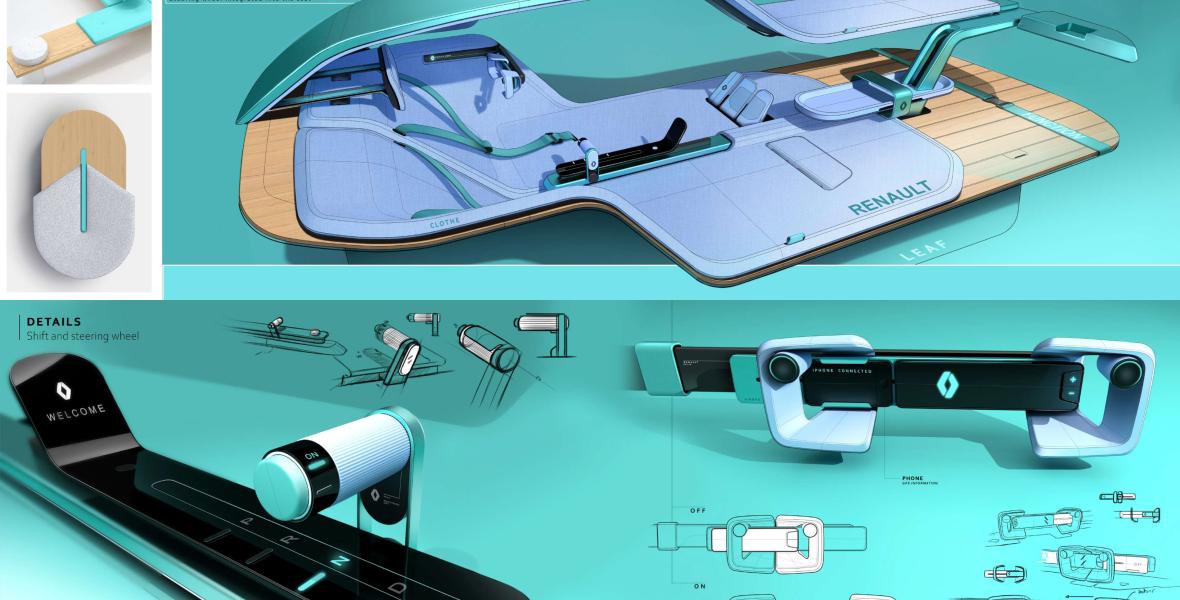

Where dreams come true

The surface designers are the hands of the designers. With full control, they model the visions and designs and create a high-defined digital master data. All technical parameters and demands considered without losing any of the aesthetical intentions. Surface design is a crucial part of the design process in automotive where highlights, features, and the overall design are in focus. Also when designing consumer products surface design can add value both in the design process and to the final product.

Our Surface design team is the largest partner in Scandinavia. We are one of the main design suppliers to all automotive OEMs in Sweden and in close collaboration with our clients, and aligned with their process, we model high-definition 3D models. With more than 30 years of experience, working across the automotive landscape from mainstream premium cars, trucks, and heavy machinery to sportscars, you find clients like Volvo Cars, Polestar, Lynk&Co, Zeekr, Scania, Volvo Trucks, and some non-automotive such as Cycleurope. We have the experience and capability of working with different scenarios like front office and core team, back office, near-shore, and off-shore.

With our own in-house team combined with an extensive partner network, we can manage outsourced projects and extended studios. Also, we source Surface designers directly into our clients’ studios. We can man up for, and take on, an entire project, or specific task, quickly and can prepare digital models for visualization, physical verification, or production tooling. The business set-up can be done with different scenarios like front office and core team, back office, near-shore, and off-shore.

We are proficient in surface modeling from early design phases, with quick modeling tools, to finished production surfaces, from CAS to Class-A including parametric modeling if requested.

We are professionals in using the business-leading tools Alias, ICEM Surf, Blender, SubD, Maya, Grasshopper, and CATIA V5.

The core of all our offers is the long-term relationship with our clients, giving us the opportunity to coach new talents to the market and creating a win-win solution for everyone.

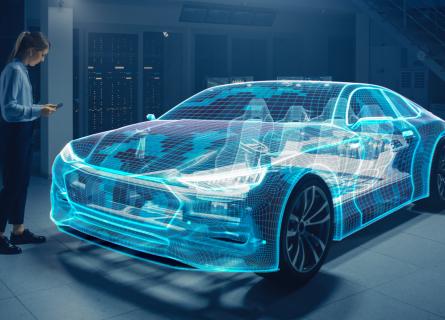

Studio engineering

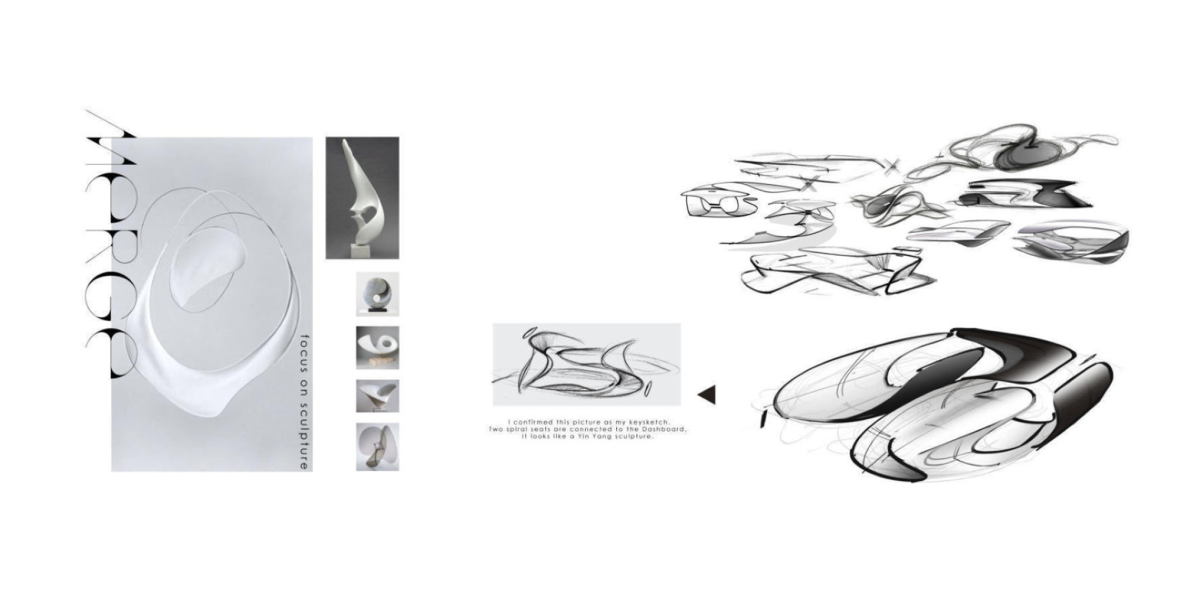

Connecting the dots

The technical feasibility development will impact and adjust the design intention in a push-the-limits but compromising funnel as the process advances toward the final design of the product. In this process and teamwork, the studio engineer is an essential link between the design engineering side and the product design side, and the assurance that the original design vision is kept as much as possible. With knowledge of the process, criteria, and constraints, and skills in communication and problem-solving, they will take the product design intent and work out an optimal and feasible solution together with the design engineering side.

With our in-house studio engineers and our extensive partner network, we support our clients’ projects either in our own studio when we develop an outsourced project or in the clients’ design studio.

Depending on the different needs and tasks in the project we will find a studio engineer with the right experience, for example interior, exterior, CMF, accessories, or non-automotive industrial design.

Physical Models and Geometry Engineering

For all your senses

In the design process it is necessary to verify the design intention and ambition according to the vision set from the beginning. The technical feasibility development will impact and adjust the design intention in a push-the-limits but compromising funnel as the process advances towards the final design of the product.

This verification process within the design process is done in an optimized combination of digital visualisation and physical models visualisation, depending on various factors.

At Experience Studios we can support you with setting up the optimal verification process and solution, for the assurance of your design reaching its full maturity and keeping the intent. Always with a focus on sustainable development and product.

We can support you with any kind of physical model to verify your product in whatever phase you are in the process, to complement the verification done by our visualisation department. This includes models such as colour, material and finish models, clay models, clinic models, ergonomic models, aerodynamic models, UX rigs, verification models, functional prototypes, concept models, show models etc.

We do some of the models together with our colleagues within AFRY, but mainly we do our models together with our partner Cliff Models & Prototypes in Gothenburg.

Our Physical Model Geometry Engineers will coordinate and execute the digital modelling and engineering activities to develop the physical models of our clients, and get them prepared for manufacturing. Either for manufacturing by our partner Cliff or by our client’s themselves.

Timing and quality of all verification is essential, but also optimized according to where in the process you are, which is something we prioritze.

In a combination of knowledge of modelling processes, material selection, model fabrication processes and assembly, and together with our partners and network we can help you with any kind of physical model or prototype.

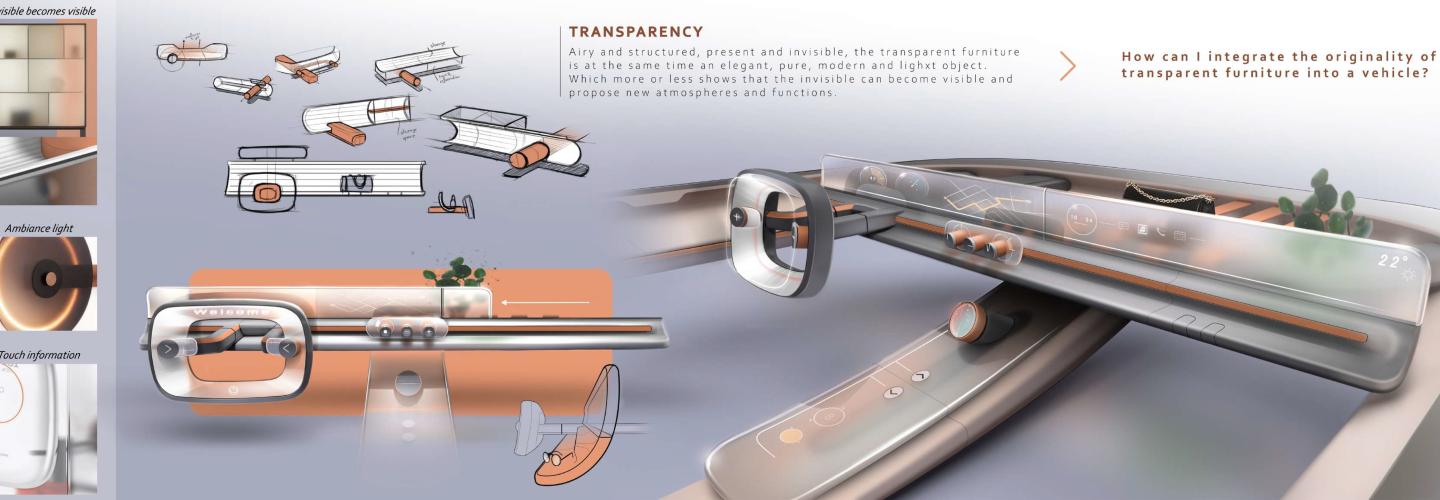

Design Quality

Don’t forget, the customer can be you

Design Quality is the support for the product appearance to achieve the right perceived quality feeling on the product. It is the result of the execution of product design, engineering, and production. Design quality should continue to improve visual quality; internal and external harmonies, fit and finish, surface and characters lines for all parts visible by the customer.

DQ Specialist is considered as eyes and voice of customers within the design team, with an eye for design and detailing. Both from the modeling aspect as well as the design intentions and engineering criteria. The DQ specialist interacts with various stakeholders with the simple goal of developing the best possible designed product.

Our DQ Specialists can support any project from the early phase until the late production phase. They can support on general design features, grain, draft angel, color, texture, gloss, and overall aspect of form. They are used to involve and communicate with suppliers, part owners, SQE, purchasers, Colour and trim designers, studio engineers and to summarize everything in DQ reporting systems.