AFRY PRS

Product Information

Digitalised Quality Management packaged in a cloud-based platform.

The PRS system is a packaged solution supporting companies to increase efficiency and minimise cost when faced with the ever-increasing amount of regulations and legislations on a global market.

Companies that develop and produce products have large amounts of data that must be collected, analysed and distributed internally and externally towards customers, suppliers or authorities for various reasons.

The PRS system applications are web-based communication and information platforms designed for traceable, customised and transparent data management both between internal stakeholders and suppliers.

With AFRY and the PRS systems, all relevant data will be efficiently collected with a high collection rate and expected benefits such as time, cost and risk reduction due to improved operational efficiency, communication and cross-functional collaboration.

AFRY offers over 20 different modules for various purposes and industries and has been achieving operational excellence since 2010.

Companies, which manufacture products, have a requirement to collect data as a part of the operational processes according to directives and regulations. The amount of information which has to be controlled and reported increases with accelerating speed with a resource-heavy process creating high cost and risks.

PRS is a web-based AFRY Product, a communication portal between companies and collaboration partners, which could be suppliers from around the globe, as well as internal colleagues. All necessary information is collected using predefined processes and the progression can easily be reviewed and followed up.

With personal logins, you reach traceability, redundancy, and quality assurance. In traditional solutions, information is often relying on individuals. The Administration is done directly in the portal for best effectivity and minimal risk. PRS’ tailormade user interfaces increase response frequency and allow easy creation and export of reports.

PRS has been developed in 2010 and used today by over 10.000 suppliers from 50 countries.

Take Control over the regulation and let it start to work for you.

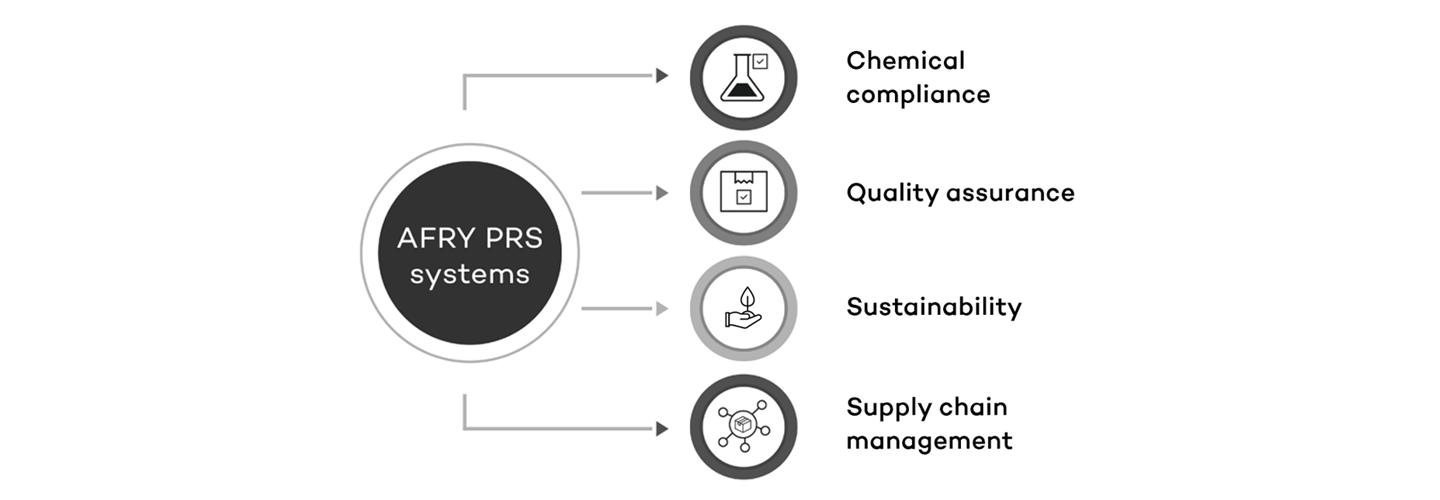

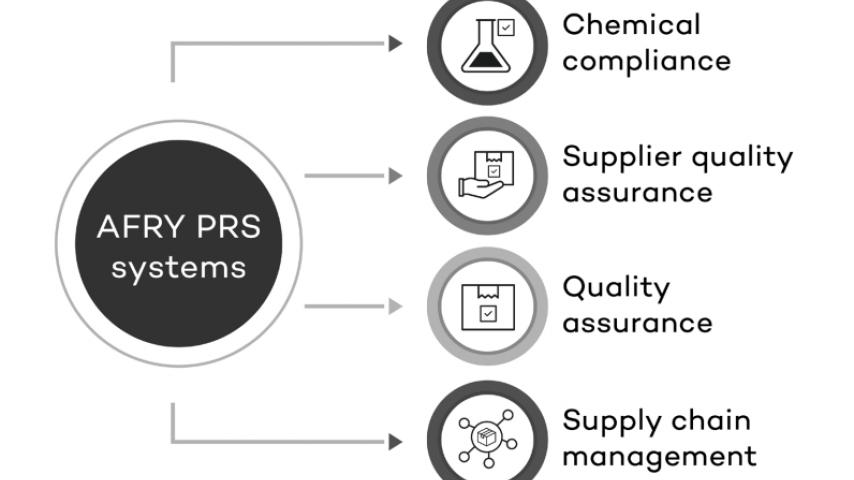

Chemical Compliance

- REACH

- RoHS

- CLP

- Battery directive

- Conflict minerals

- Food contact materials

- PoPs

- Black and grey lists

Quality Assurance

Communication and management of product and parts data, used in quality assurance and appearance approval processes.

Supply Chain Management

- Supply chain mapping

- Risk analysis

- Secure business continuity

- Increase supply chain traceability

- Increase transparency

Sustainability

- Measurement

- Analysis

- Monitoring of corporate social responsibility work

- Sustainable business performance indicators

Common customer challenges

Over the years, we have gathered experience from numerous customer assignments in many industries. This means that we have received an overview of the challenges many customers face.

Regulatory growth

Regulatory growth and increasing demands from customers and authorities globally. It can be difficult to navigate the amount of laws, regulations and standards.

Keep an eye out for our seminars and read more about Sustainable Safety on tour

Wide product portfolios and Suppliers worldwide

Wide product portfolios with many articles and components sold in a global market mean challenges, especially in compliance with, for example, REACH and CLP, labels and product data sheets / safety data sheets.

Suppliers all over the world, with limited knowledge of statutory requirements and obligations in complex supply chains.

Lack of integrated systems & Manual data management

Defined processes and methods that are not integrated with existing systems.

Extensive data management without reliable data or sufficient tools, often time-consuming manual work without systematic data collection

Benefits

Using PRS system clients experience shorter lead time, reduced costs and decreased risks

Reference projects show reduced time, cost and risk due to improvement of:

-

Operational efficiency

-

Communication

-

Cross-functional collaboration

-

Quality of data

-

Traceability

-

Security

-

Response rates