Schils small hydro power plant in Flums, Switzerland, designed with BIM

The pioneering BIM project: collaborative planning and model-based construction without 2D plans

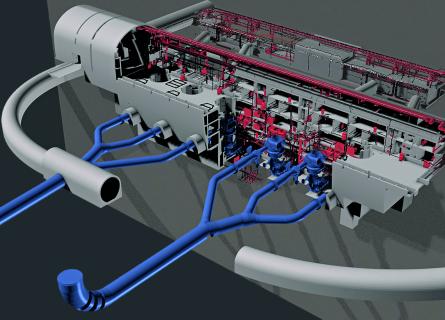

The Schils hydropower plant in Flums is an important supplier of electricity in the region. AFRY was commissioned with the entire planning of the plant from the preliminary project onwards, including construction management and commissioning. The project was carried out as a 3D model-based Building Information Modeling (BIM) project end-to-end.

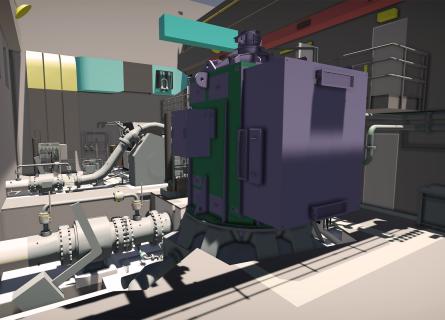

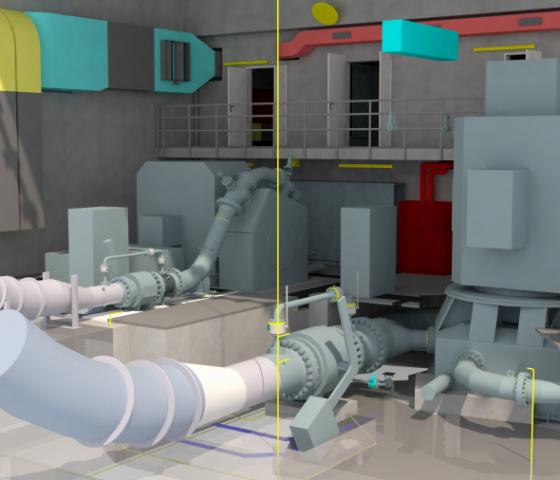

The refurbishment of the some 100-year-old Schils hydropower plant includes the removal of the previous intermediate stage in Pravizin, the partial replacement of two penstocks, and the construction of the new Flums control centre with a total installed capacity of 13 MW.

- The penstocks between the former Pravizin stage and the new Flums control centre were replaced by two steel penstocks with diameters of 1000 mm (Bruggwiti pressure system, approx. 500 m water pressure) and 600 mm (Aeuli pressure system, approx. 400 m water pressure)

- The flow of water is turbined by two Pelton turbines (10.9 MW / 2.1 MW) in the new Flums control centre and fed back into the Schils. In addition to the machine hall, the Flums control centre includes various rooms for equipment and building services, as well as control rooms for power plant operation

The client, planners, suppliers and contractors jointly developed the various structures using 3D computer models.

VDC|BIM offers many advantages

KW Schils is a pioneering project for the application of VDC|BIM in hydropower. It enables collaborative and joint development and facilitates coordination prior to its execution, resulting in increased reliability and a high degree of optimisation in planning. This reduces the need for amendments during construction planning and problems during execution, resulting in fewer change orders and greater reliability in scheduling and costs.

The work was consequently model-based throughout the entire coordination and implementation phase. As a result, many detailed issues were clarified early on using the digital model, which practically eliminated problems during execution and installation. The construction was performed with the model-based BIM2field method, without using traditional 2D paper plans.

System technical data

Bruggwiti:

- Discharge water volume: 2.6 m³/s

- Gross head: 491 m

- Length of pressure pipe renewed: 514 m

- Diameter: 1000 mm

- Installed capacity: 10.9 MW

- Turbine type: 5-nozzle Pelton, vertical axis

- Annual production: 43 GWh

Aeuli:

- Discharge water volume: 0.7 m³/s

- Gross head: 368 m

- Length of penstock renewed: 514 m

- Diameter: 600 mm

- Installed capacity: 2.1 MW

- Turbine type: 2-nozzle Pelton, horizontal axis

- Annual production: 7 GWh

Project facts

Client

SAK (St. Gallisch-Appenzellische Kraftwerke)

Services provided

General planning, structural planning and technical planning for the following phases:

- SIA 31 Preliminary project

- SIA 32 Construction project

- SIA 33 Authorisation procedure

- SIA 41 Tenders

Contract procedures:

- SIA 51 Implementation planning

- SIA 52 Execution

- SIA 53 Commissioning

General contractor for the coordination of all trades involved using the VDC|BIM method, model-based planning and realisation:

- 3D models

- BIM

- VDC|BIM method

- Extended BIM use cases, BIM4D, BIM5D

- BIM2field (model-based construction site without 2D plans) with two different contractors

Project duration

2016—2021