Machinery Safety

The key to a successful and sustainable operation

Machinery Safety equals best-in-class machine performance. It equals fewer risks, an improved and increased output, and a safer operating environment. We call it a win-win scenario. And it’s why safety has been part of AFRY’s DNA for over 125 years.

As the center of excellence at AFRY for the human-technology-organization perspective, we enable our clients to extract the full potential of digitalization while maintaining and enhancing the safety culture.

Our machinery safety team consists of specialists, experts, and EN & ISO developers with a deep understanding of the regulations, directives, and standards that our clients demand. No matter whether the scope of work concerns a single piece of equipment or an entire production line, we consider every directive and advise our clients on all relevant certifications.

At AFRY, our work with machinery safety dates back to 1895. Back then, we performed safety inspections on steam boilers. And since then, our expertise has expanded to include a wide range of industry safety areas.

Given this extensive background, we know how to adapt our approach. We always listen to our clients and shape the safety work to be understandable, manageable and a source of value creation.

Igor Bogunic

Manager Safety & EHS

Our offer

Risk assessment

In each step of our risk assessment, we use a quality assured and systematic approach.

Our process includes:

- identification

- assessment

- evolution

- reduction

- final documentation

This method addresses all unforeseen threats and costs.

Safety PLC

For a Programmable Logic Controller (PLC) to be considered a Safety PLC, it must meet a set of rigorous international standards. It can be a long and difficult journey.

At AFRY, however, we guide our clients smoothly through every step.

We certify and verify Safety PLCs and support regarding its implementation. Should the client require programming as well, we partner with our Automation experts in-house.

Pressure Equipment Directive (PED)

At AFRY, we advise clients on the Pressure Equipment Directive (PED) (2014/68/EU). At every stage, our consultants provide substantial guidance. We assess the:

- design

- manufacturing

- conformity

With our experience – regardless if it’s a pressure vessel, pressure accessory, piping, or safety accessory – the machine will reach the market faster.

ATEX

Flammable substances such as gases, mists, vapor, or combustible dust can create a potentially explosive atmosphere in the workplace.

To prevent accidents, our consultants support regarding the ATEX directives (99/92/EC and 2014/34/EU). Moreover, we perform explosion and ignition risk assessments and deliver instructions for maintenance and training.

CE marking

CE marking is obligatory for products where EU specifications exists. It’s also required for products that require an affixed CE mark.

We manage our client’s needs for the entire CE marking process according to the Machinery Directive, including:

- analysis

- risk assessment

- quality assurance

- technical documentation

- training

- software

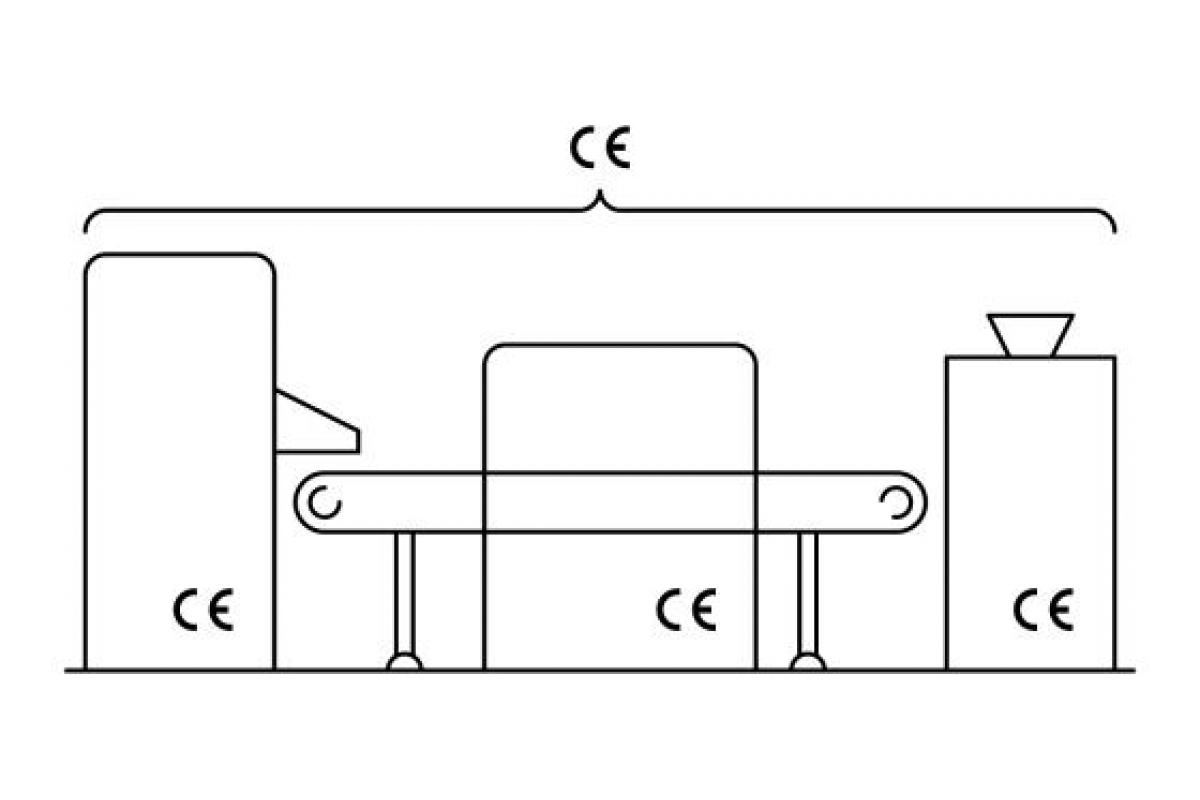

At AFRY, we assess individual machines as well as plants – both of which require proper review.

Also, we offer specialized solutions, such as reviews of existing material.

How we certify entire production lines

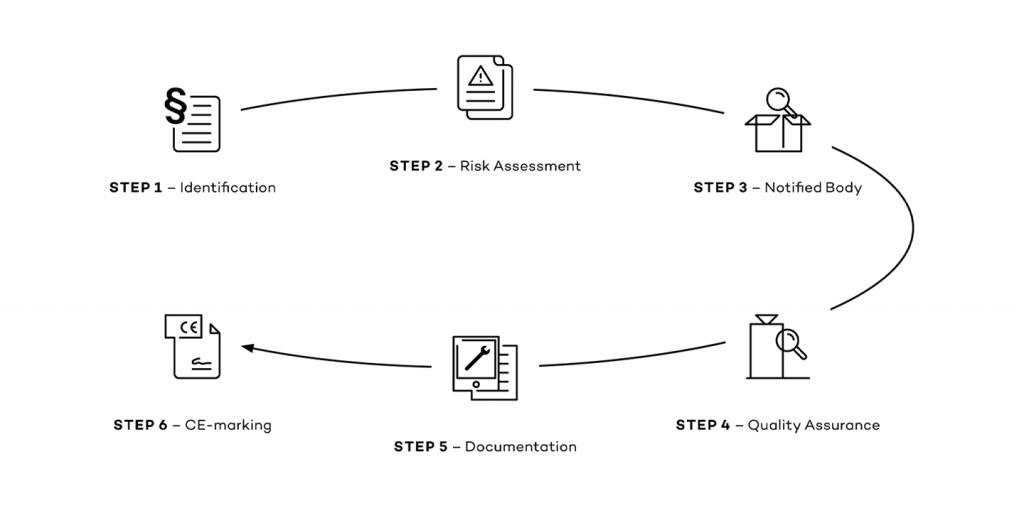

Our quality assured and verified Machinery Safety process, in its entirety, starts with us identifying the relevant directives. After that, we assess the risks. We always conduct in-depth reviews before the product is tested and verified.

Safety also forms a core part of the documentation. Our technical communications team ensure that the manuals conform stylistically as well as legally.

Finally, the client can confidently sign the declaration of conformity, and the CE mark is applied.

STEP 1 – Identification: Identify directives and harmonized standards for the product. 765/2008, article 30.

STEP 2 – Risk Assessment: Verify product-specific requirements. Determine intended use and foreseeable misuse. Evaluate > Eliminate/reduce.

STEP 3 – Notified Body: Review if an independent assessment is required.

STEP 4 – Quality Assurance: Test and verify the compliance for all products.

STEP 5 – Documentation: Compile the Technical Construction File and Information of use. The TCF needs to be available for 10 years.

STEP 6 – CE-marking: Apply the CE-mark on the product and sign the declaration of conformity.

Information and strategy that adds value

Frequently Asked Questions

- Is Machinery Safety required by law?

- Can Machinery Safety reduce costs?

- What industries does AFRY support?

CE marking according to the Machinery Directive, for example, is mandatory for products for which EU directives or regulations exist and for products that require a CE mark affixed.

In some cases, a review may be sufficient.

At AFRY, we support with CE marking and reviews in collaboration with clients.

Machinery Safety is an investment in a future financial security. A safe machine has a higher output and less waste. And, at the same time, it eliminates medical costs, litigations, settlements, and declines in overall productivity.

Moreover, Machinery Safety protects the most valuable asset: the employees.

Our primary focus has been manufacturing and process industries such as Pharma, Food, Pulp and Paper, Construction, High-tech, Mining and Minerals etc. During the past four decades, AFRY has expanded its focus to manage safety in Energy, Infrastructure and digital safety solutions.

Combined Competencies

Interested in our offering? Contact us!